Inner wall anti-corrosion process suitable for thin and short HDPE corrugated pipe

A corrugated pipe and process technology, which is applied in the field of corrugated pipe anticorrosion technology, can solve problems such as difficult coating, difficult spraying of corrosion inhibitors, easy existence of blind spots, etc., and achieve the effect of large economical and practical benefits and efficient coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

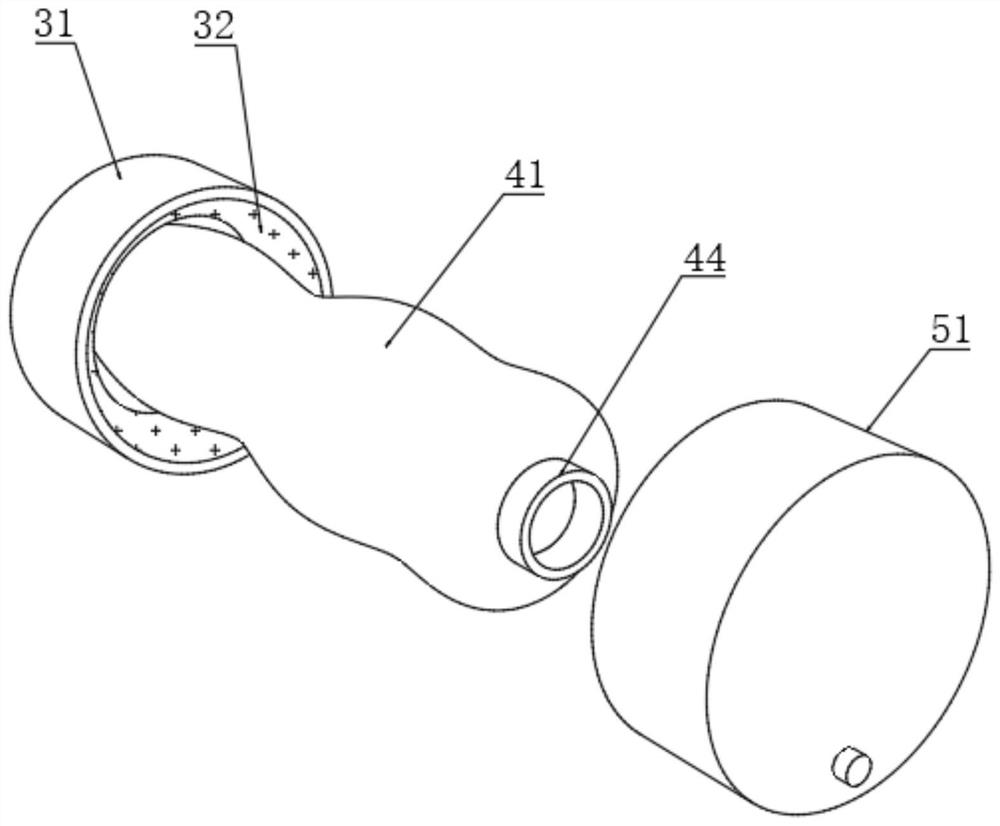

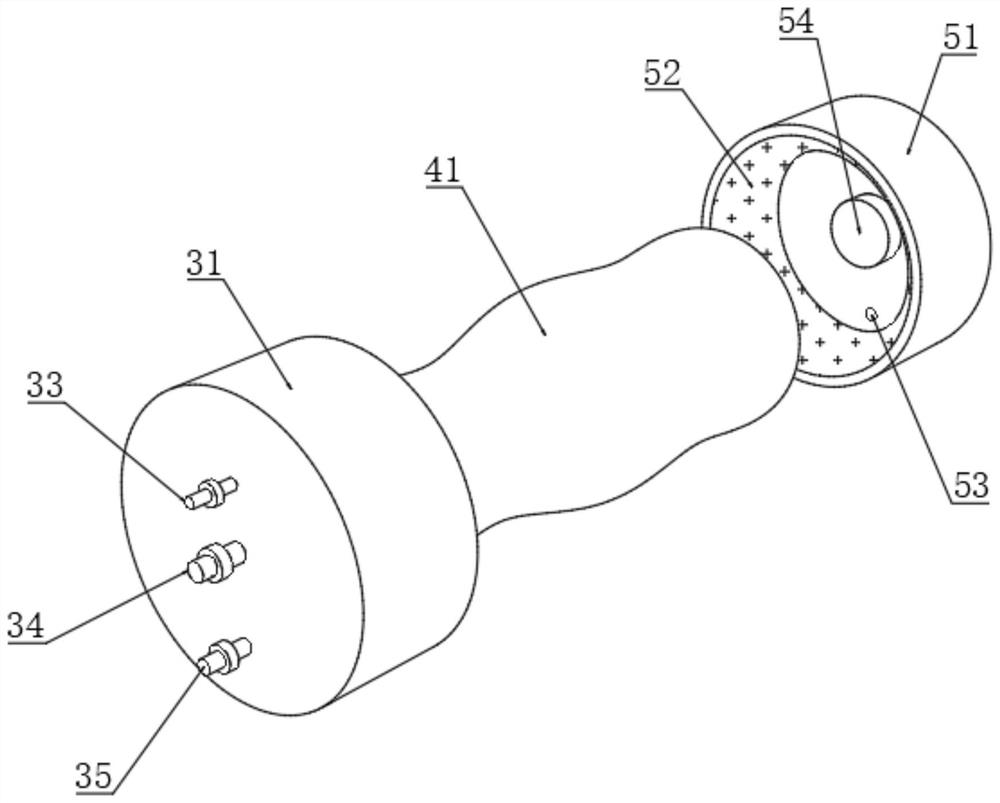

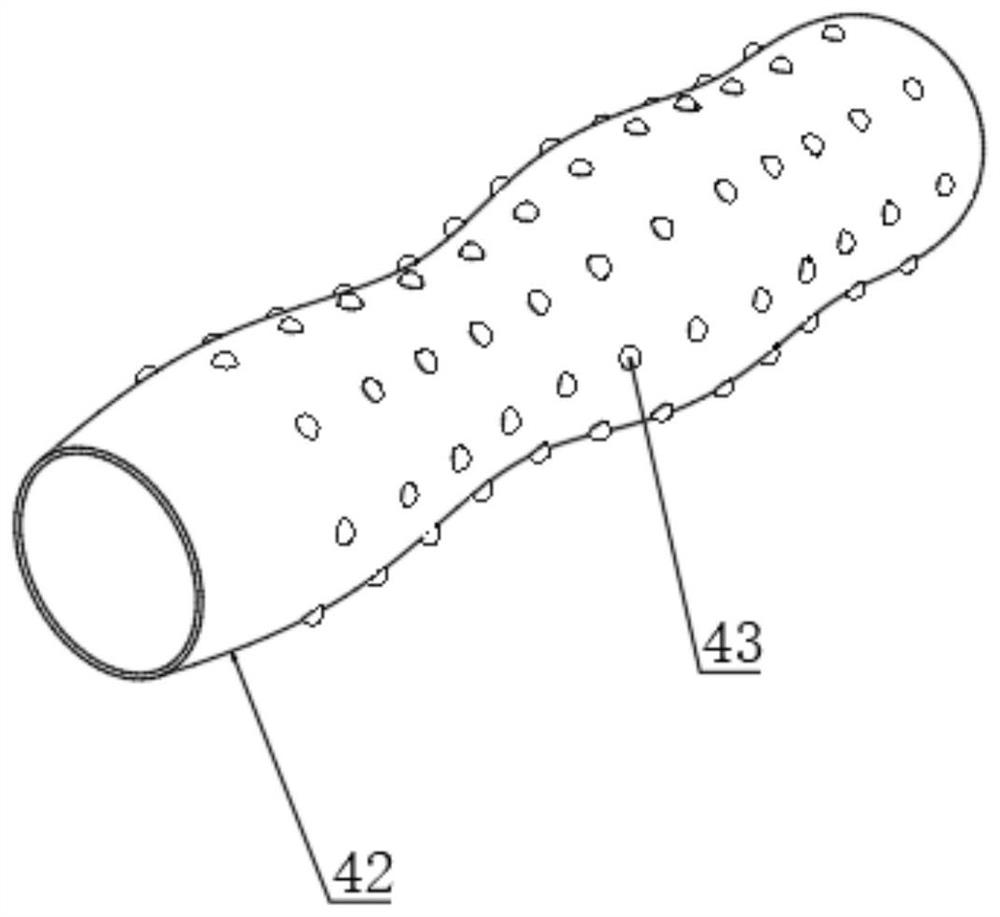

[0048] see figure 1 with image 3 , an inner wall anti-corrosion process suitable for thin and short HDPE corrugated pipes, comprising the following steps:

[0049] S1. Prepare coating tools: multi-port front cover, double-layer film sleeve and single-port rear cover;

[0050] S2, put the pipe body n to be processed on the outside of the double-layer film cover, such as Figure 5 shown;

[0051] S3. The air in the outer cavity of the double-layer membrane sleeve is drawn out through the multi-port front cover to form a vacuum state, and air is introduced into the inner cavity of the double-layer membrane sleeve to expand the double-layer membrane sleeve and form with the inner wall of the tube body In the semi-open contact state, the multi-port front cover and the single-port rear cover are respectively placed on both ends of the tube body n, such as Image 6 shown;

[0052] S4. Pass a sufficient amount of anti-corrosion coating between the double-layer membrane sleeve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com