Precise hole machining method for glue-containing laminated material

A hole processing method and a technology of laminated materials, which are applied in the field of aerospace parts preparation, can solve the problems of poor hole position accuracy and aperture accuracy, and meet the requirements of ensuring correctness and processing efficiency, ensuring position accuracy and aperture accuracy , Guarantee the effect of hole processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

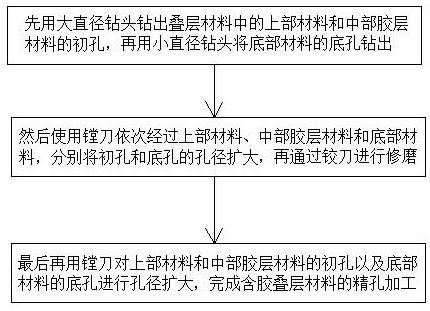

[0029] see figure 1 , a method for fine hole processing of glue-containing laminated materials, comprising the following steps:

[0030] a. First use a large-diameter drill to drill the initial holes of the upper material and the middle adhesive layer material in the laminated material, and then use a small-diameter drill to drill the bottom hole of the bottom material;

[0031] b. Then use the boring tool to pass through the upper material, the middle rubber layer material and the bottom material in sequence, respectively expand the aperture of the initial hole and the bottom hole, and then use the reamer for grinding;

[0032] c. Finally, use a boring tool to enlarge the hole diameter of the initial hole of the upper material and the middle rubber layer material and the bottom hole of the bottom material to complete the fine hole processing of the glue-containing laminated material.

[0033] "a. First use a large-diameter drill to drill the initial holes of the upper materi...

Embodiment 2

[0035] see figure 1 , a method for fine hole processing of glue-containing laminated materials, comprising the following steps:

[0036] a. First use a large-diameter drill to drill the initial holes of the upper material and the middle adhesive layer material in the laminated material, and then use a small-diameter drill to drill the bottom hole of the bottom material;

[0037] b. Then use the boring tool to pass through the upper material, the middle rubber layer material and the bottom material in sequence, respectively expand the aperture of the initial hole and the bottom hole, and then use the reamer for grinding;

[0038] c. Finally, use a boring tool to enlarge the hole diameter of the initial hole of the upper material and the middle rubber layer material and the bottom hole of the bottom material to complete the fine hole processing of the glue-containing laminated material.

[0039] In the step a, the large-diameter drill bit drills out the rubber layer material in...

Embodiment 3

[0043] see figure 1 , a method for fine hole processing of glue-containing laminated materials, comprising the following steps:

[0044] a. First use a large-diameter drill to drill the initial holes of the upper material and the middle adhesive layer material in the laminated material, and then use a small-diameter drill to drill the bottom hole of the bottom material;

[0045] b. Then use the boring tool to pass through the upper material, the middle rubber layer material and the bottom material in sequence, respectively expand the aperture of the initial hole and the bottom hole, and then use the reamer for grinding;

[0046] c. Finally, use a boring tool to enlarge the hole diameter of the initial hole of the upper material and the middle rubber layer material and the bottom hole of the bottom material to complete the fine hole processing of the glue-containing laminated material.

[0047] In the step a, the large-diameter drill bit drills out the glue layer material in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com