Aluminum profile surface treatment equipment and surface treatment method thereof

A technology for surface treatment and surface treatment layer, applied in metal processing equipment, grinding/polishing equipment, abrasive surface conditioning devices, etc. Profile processing and other issues, to achieve the effect of improving the reuse rate, improving the adequacy and diversity, and sufficient surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

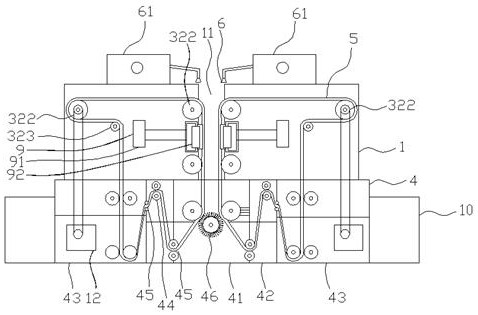

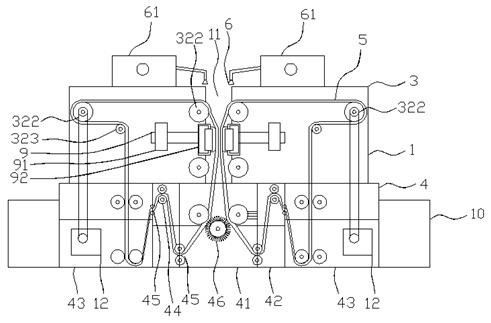

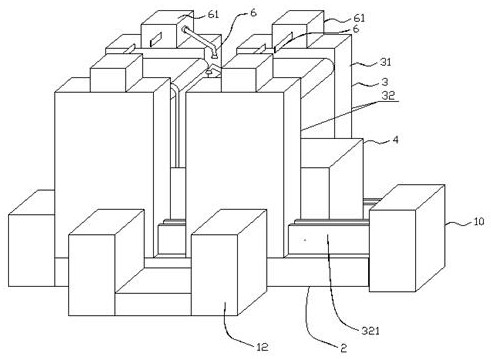

[0037] Such as Figure 1~Figure 4 As shown, an aluminum profile surface treatment equipment 1 includes a base 2, a pair of parallel slide rails are arranged on the base 2, a purification treatment box 4 is arranged between the slide rails, and the purification treatment box 4 is located between a pair of parallel slide rails between. A pair of opposing surface treatment racks 3 are slidably arranged on the slide rails, and each surface treatment rack 3 is provided with multiple sets of transfer rollers 322 , and a closed-loop surface treatment belt 5 is sheathed outside the transfer rollers 322 . The upper part of the surface treatment frame 3 is provided with a treatment liquid spray head 6 corresponding to the outer surface of the surface treatment belt 5 for spraying a treatment solvent for the surface treatment of aluminum profiles.

[0038] Specifically, such as Figure 1~Figure 3As shown, both sides of the purification treatment box 4 are respectively straddled with a ...

Embodiment 2

[0042] Such as Figure 1~Figure 4 As shown, a surface treatment method of aluminum profile surface treatment equipment 1 comprises the following steps,

[0043] Step 1, hang and load the aluminum profile onto the conveyor rack. Specifically, the four-corner positioning of the suspended loaded aluminum profiles is carried out through the transmission frame to improve the positioning stability of the aluminum profiles.

[0044] Step 2, driving the external transmission frame, and sequentially transmitting the suspended loaded aluminum profiles through the operation transmission area 11 between the surface treatment frames 3 arranged oppositely.

[0045] Step 3, by driving the surface treatment belt 5 on the opposite surface treatment frame 3 to move relative to each other, so that the frosted area 521 on the surface treatment belt 5 and the flexible painting area 522 with the processing solvent are sequentially applied to the operation transmission area 11. The aluminum profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com