Anti-adhesion surface for rubber die as well as preparation method and application for anti-adhesion surface

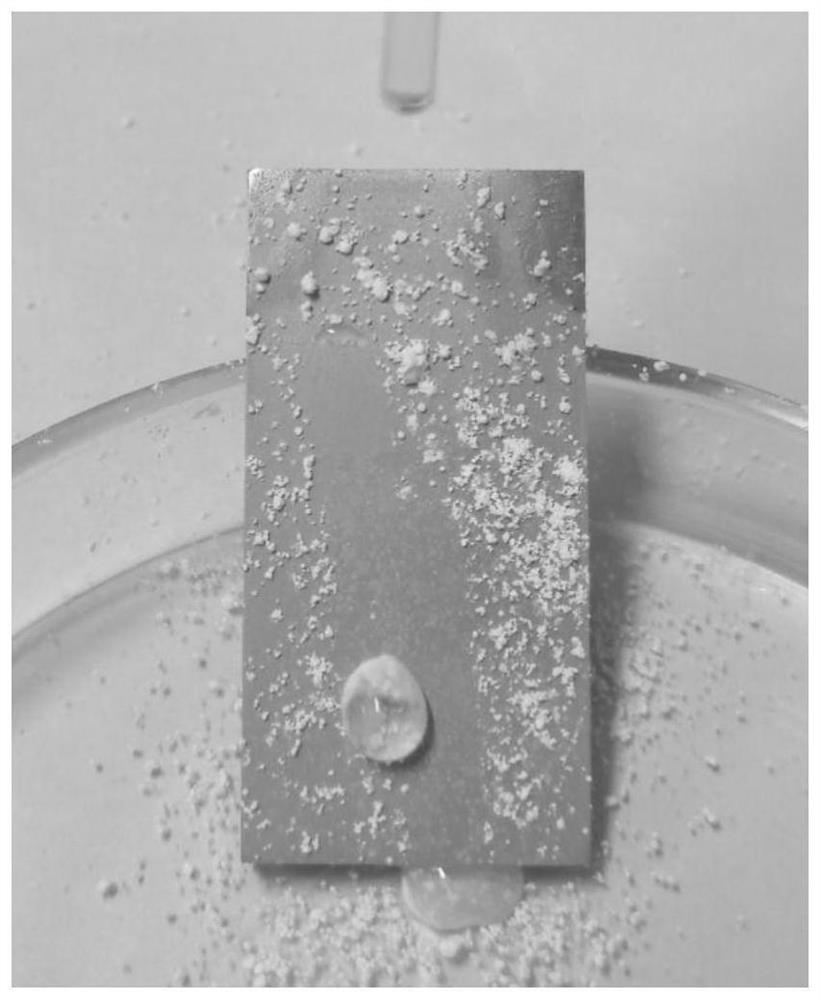

A rubber mold and anti-adhesion technology, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of high energy consumption and material consumption, expensive equipment, complicated process, etc., to improve performance and service life, and effectively Adsorption and storage, simple and adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Use 600-2000 mesh sandpaper to grind and polish the surface of 6082 aluminum alloy (Ra=0.05-0.1μm), then put the substrate into absolute ethanol and deionized water for ultrasonic cleaning, and finally put the substrate into the oven Dry in vacuum for later use.

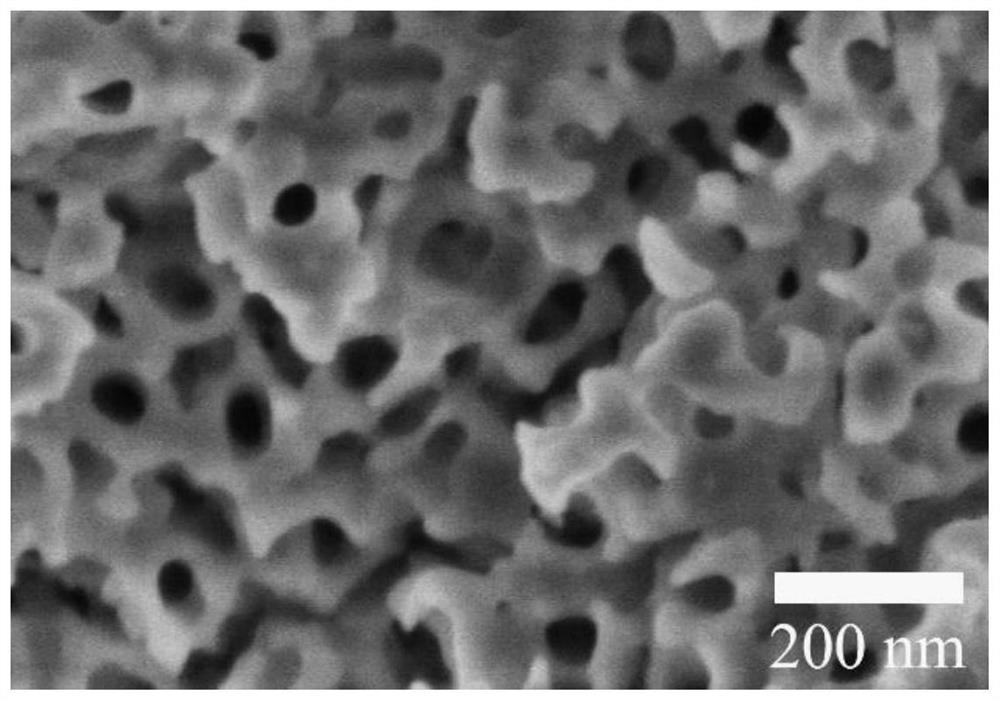

[0033] 2. Put the substrate treated in step 1 as an anode into a 40g / L phosphoric acid electrolyte, the cathode is an aluminum alloy with the same area as the anode, the distance between the two electrodes is 20mm, and the temperature of the electrolyte is 10°C. Set the anodizing current density to 20A / dm 2 , time 10min. Put the anodized metal surface into deionized water for ultrasonic cleaning, and then dry it naturally for use.

[0034] 3. Soak the anodized metal surface treated in step 2 in molten palmitic acid (palmitic acid) for 20 minutes, and then put the soaked surface into absolute ethanol for ultrasonic cleaning for 2 minutes.

[0035] 4. Add Krytox 100 dropwise to the metal surface treated in...

Embodiment 2

[0037]1. Use 600-2000 mesh sandpaper to grind and polish the surface of the metal mold substrate 6082 aluminum alloy to make the surface roughness Ra=0.05-0.1μm, and then put the substrate into absolute ethanol and deionized water for ultrasonication After cleaning, the substrate is put into an oven for vacuum drying for later use.

[0038] 2. Put the substrate treated in step 1 as the anode into a 50g / L phosphoric acid electrolyte, the cathode is an aluminum alloy with the same area as the anode, the distance between the two electrodes is 25mm, and the temperature of the electrolyte is 15°C. Set the anodizing current density to 25A / dm 2 , time 15min. Put the anodized metal surface into deionized water for ultrasonic cleaning, and let it dry naturally for later use.

[0039] 3. Soak the anodized metal surface treated in step 2 in molten palmitic acid (hexadecanoic acid) for 20 minutes, and then put the soaked surface into absolute ethanol for ultrasonic cleaning for 2 minute...

Embodiment 3

[0043] 1. Use 600-mesh to 2000-mesh sandpaper to polish and polish the surface of the metal mold substrate, then put the substrate in anhydrous ethanol and deionized water for ultrasonic cleaning, and finally put the substrate in an oven for vacuum drying for later use .

[0044] 2. Put the substrate treated in step 1 as an anode into a 50g / L phosphoric acid electrolyte, the cathode is an aluminum alloy with the same area as the anode, the distance between the two electrodes is 30mm, and the temperature of the electrolyte is 15°C. Set the anodizing current density to 25A / dm 2 , time 20min. Put the anodized metal surface into deionized water for ultrasonic cleaning, and let it dry naturally for later use.

[0045] 3. Soak the anodized metal surface treated in step 2 in molten stearic acid (octadecanoic acid) for 15 minutes, and then put the soaked surface into absolute ethanol for ultrasonic cleaning for 2 minutes.

[0046] 4. Add all FC-70 dropwise to the metal surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

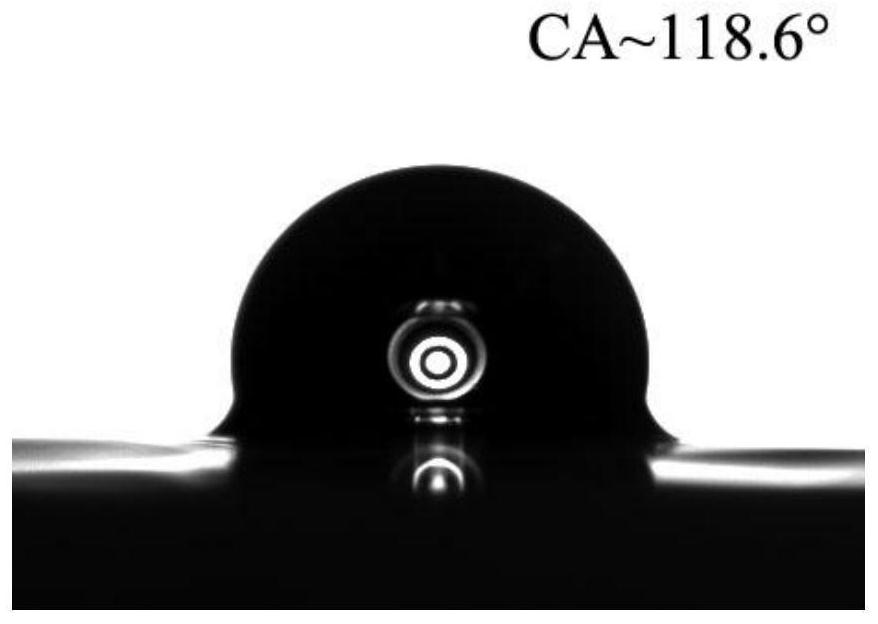

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com