Brick paving device capable of automatically adjusting brick placing direction

An automatic adjustment and brick laying device technology, applied in the field of mechanical engineering, can solve the problems of low convenience and complex structure, and achieve the effects of improving brick laying efficiency, easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

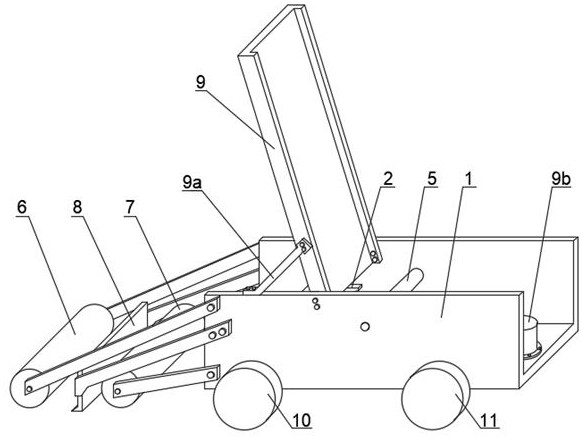

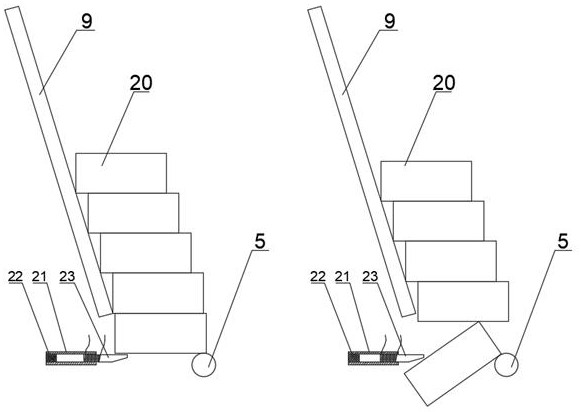

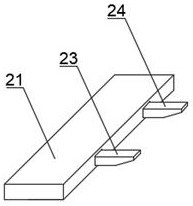

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and implementation methods.

[0022] Such as figure 1 As shown, a brick laying device that can automatically adjust the direction of laying bricks includes a box body 1, a lock brick assembly 2 and a brick swing assembly 3 are arranged inside the box body 1, a wheel shaft 4 is provided at the bottom, and the side of the lock brick assembly 2 A rotating shaft 5 is provided; a front pressure roller 6 and a rear pressure roller 7 are arranged on the outside of the box body 1, and the two are hingedly connected with the box body 1, and the front pressure roller 6 and the rear pressure roller 7 can rotate around the rod, so that The soil layer is compacted; between the front pressure roller 6 and the rear pressure roller 7, a shovel plate 8 is fixedly connected to the box body 1, and the shovel plate 8 can level the soil on the ground, thereby Ensure the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com