A steel sheet pile cofferdam

A technology of steel sheet pile cofferdams and cofferdams, which can be used in construction, infrastructure engineering, etc., and can solve problems such as difficulty in pulling out steel sheet piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-5 The application is described in further detail.

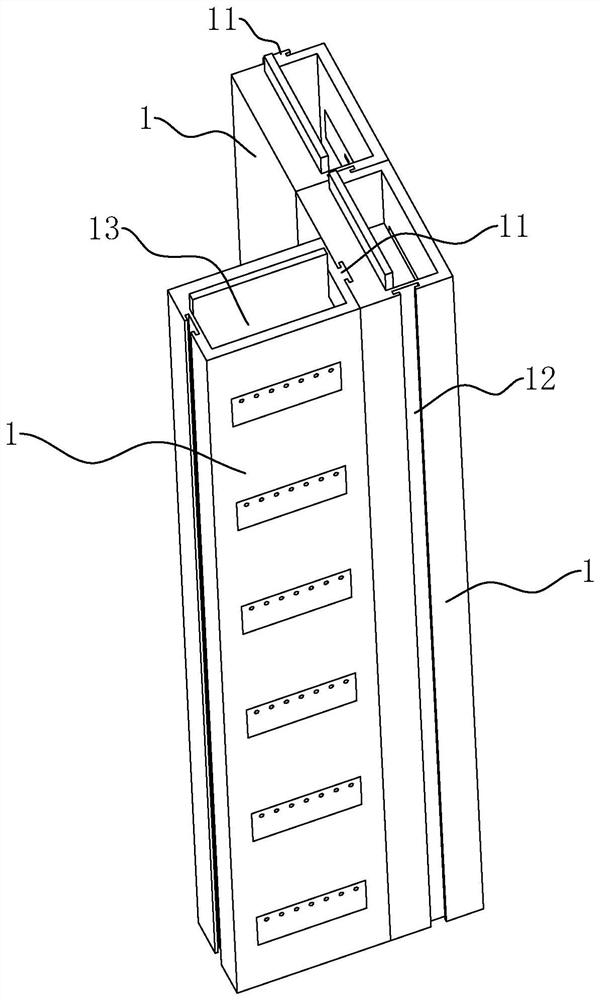

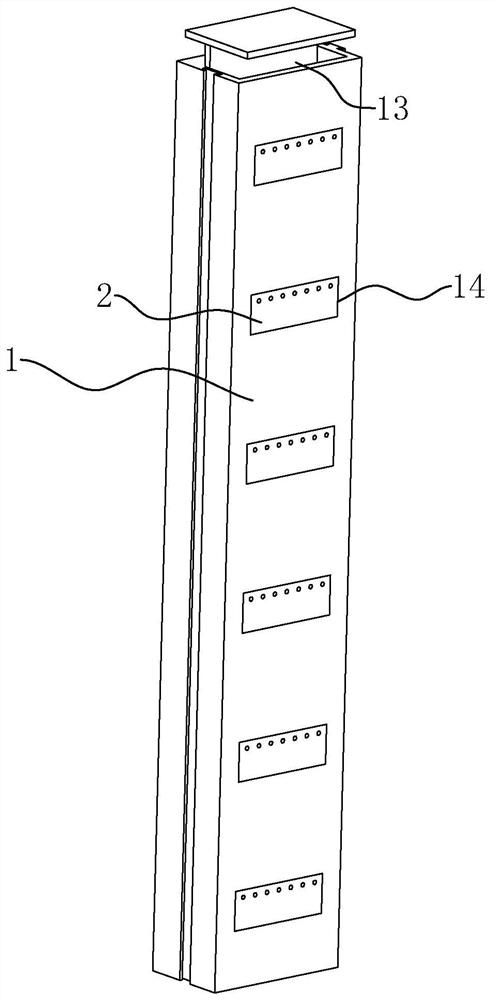

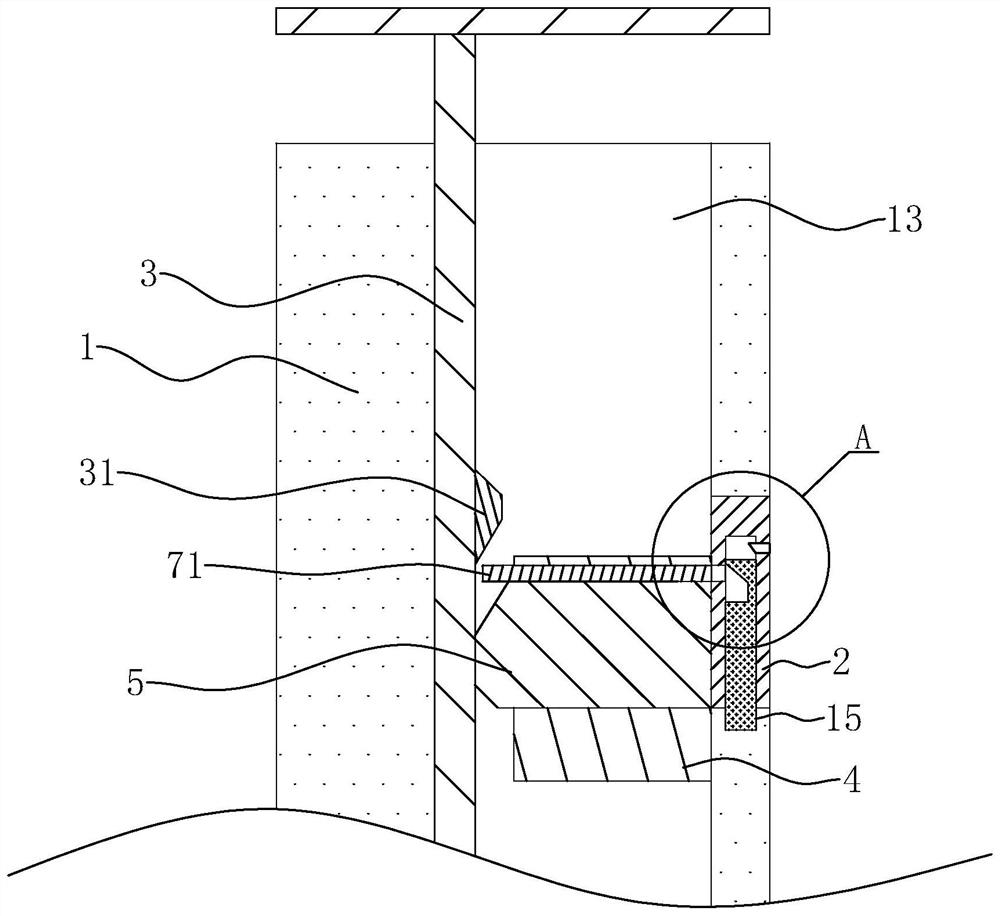

[0034] The embodiment of the present application discloses a steel sheet pile cofferdam, referring to figure 1 , figure 2 , comprising a number of piles 1, two piles 1 are fixedly connected with a T-shaped block 11 along the length direction on one of the outer walls facing each other, and a connecting pile is provided along the length direction on the outer wall of the pile body 1 away from the T-shaped block 11 The T-shaped grooves 12 at the upper and lower ends of the body 1, and the T-shaped block 11 on one pile body 1 are plugged and fitted into the T-shaped groove 12 of the other pile body 1, so that the two pile bodies 1 are connected together. A T-shaped groove 12 is also provided on the side wall facing the inner side of the cofferdam on the pile body 1 at the corner of the cofferdam, and the pile body 1 at the corner of the cofferdam is inserted into the T-shaped block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com