Novel impact-resistant shock-resistant belt pulley

An impact-resistant, pulley technology, used in belts/chains/gears, components with teeth, gear lubrication/cooling, etc., can solve the problems of reducing the service life of the pulley, weak anti-vibration and shock performance, affecting the pulley transmission, etc. The effect of accelerating heat dissipation, improving service life and preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

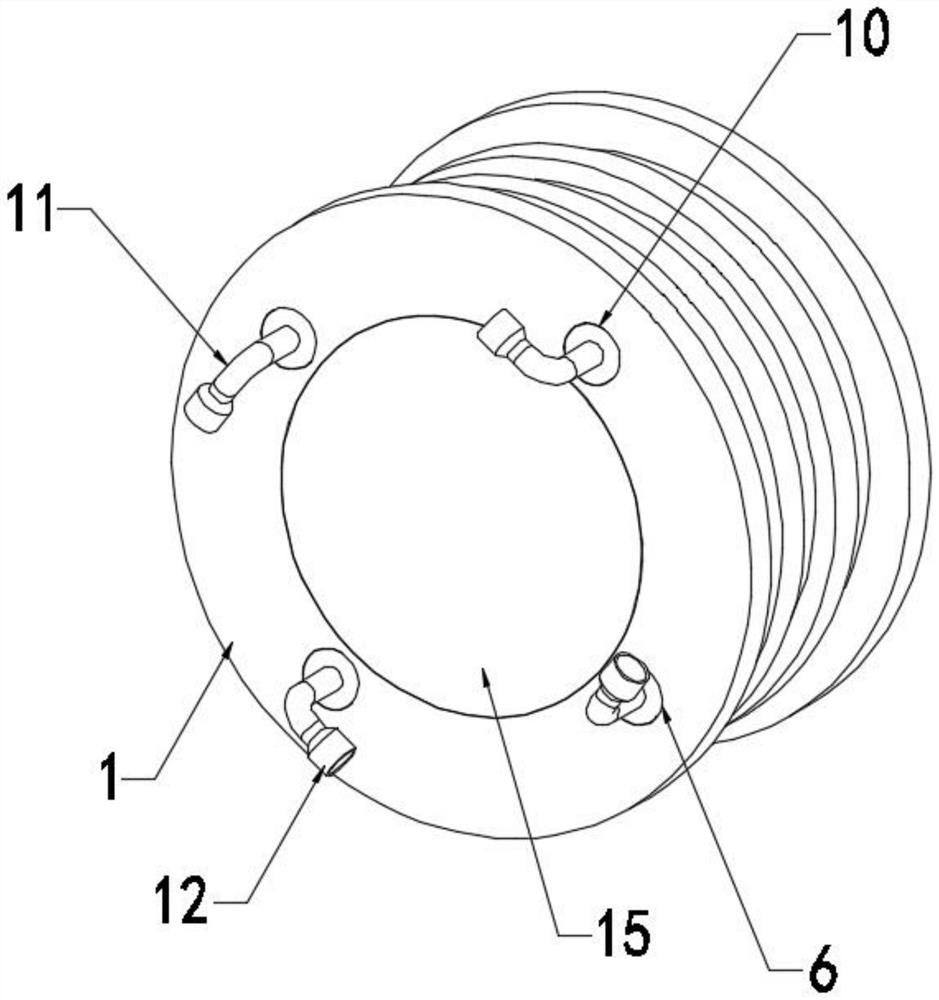

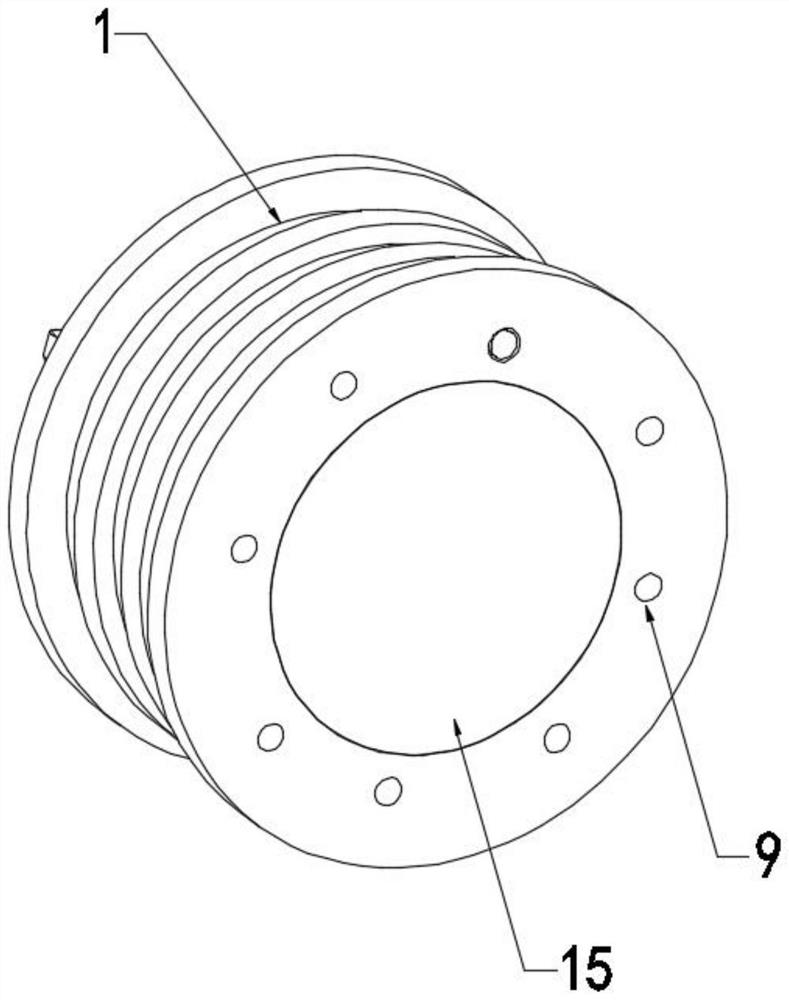

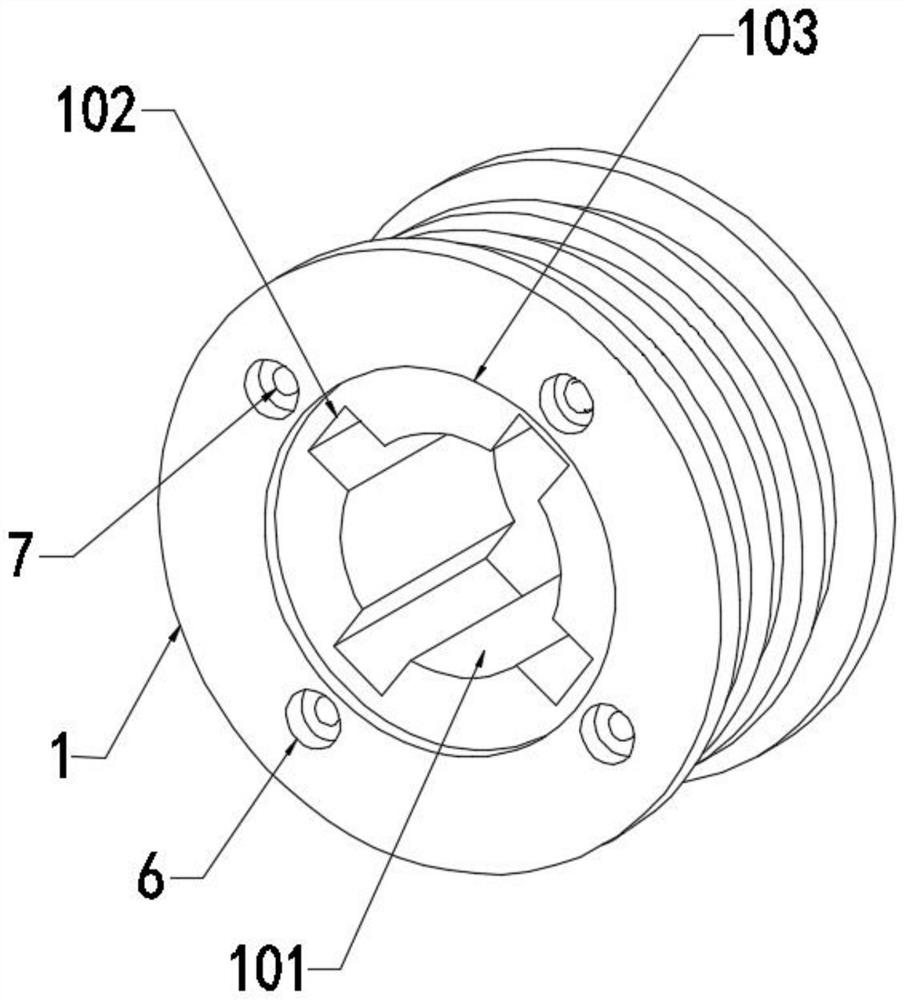

[0038] see Figure 1-7 , the present invention provides a technical solution: a new type of shock-resistant and anti-seismic belt pulley, including an outer hub 1, a circular groove 101 and a plurality of square grooves 102 are opened in the outer hub 1, the square grooves 102 communicate with the circular grooves 101, and the circular grooves 101 Internally connected with an inner shaft 2, the inner shaft 2 is fixedly mounted with a plurality of squares 3 inserted into the square groove 102. The width of the square 3 is smaller than the width of the square groove 102. The two sides of the square 3 are elastically connected with the first spring 4, and the first spring The free end of 4 is elastically connected with the inner surface wall of the square groove 102, and the two sides of the outer hub 1 are provided with installation grooves 103, and the installation groove 103 is provided with an installation cover 15, and the installation cover 15 is fixedly installed with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com