Hot water recirculation system used for flue gas waste heat recovery

A recirculation system, flue gas waste heat technology, applied in the direction of climate sustainability, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problem of easy blockage of filter holes, and achieve the effect of increasing filtering effect and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

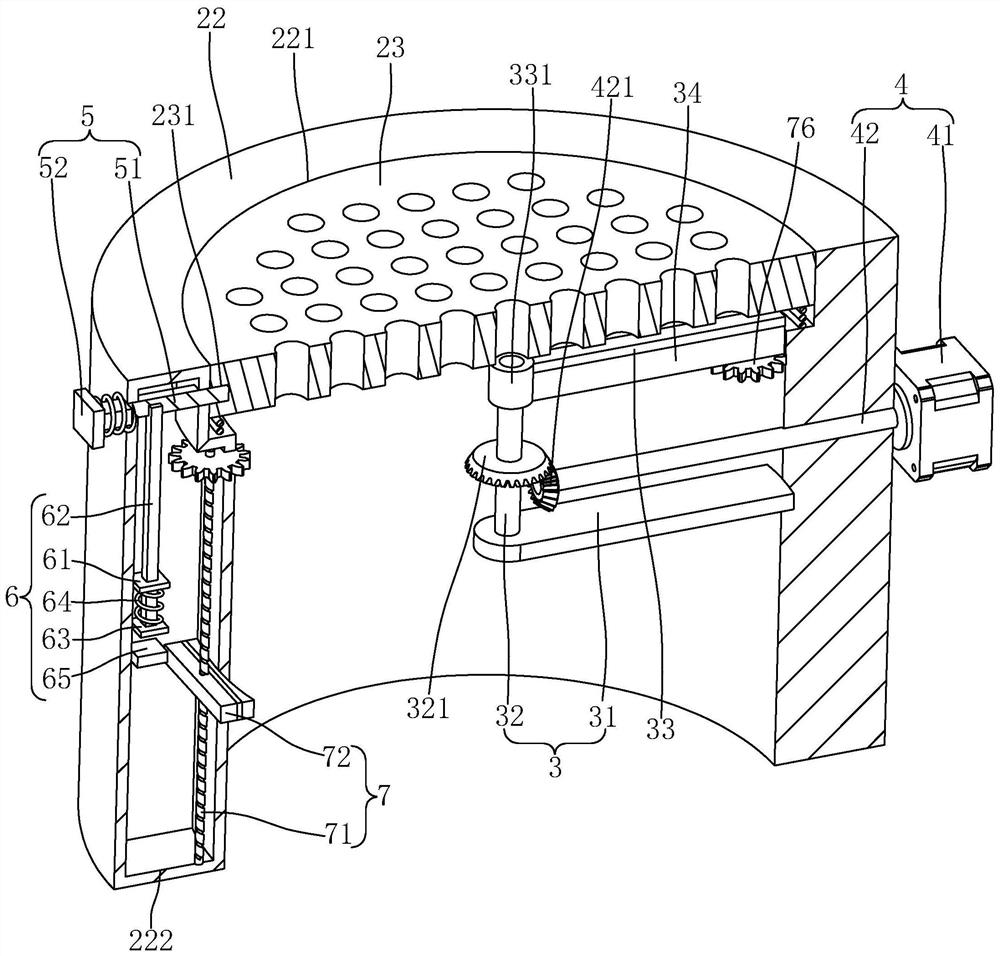

[0032] The following is attached Figure 1-4 The application is described in further detail.

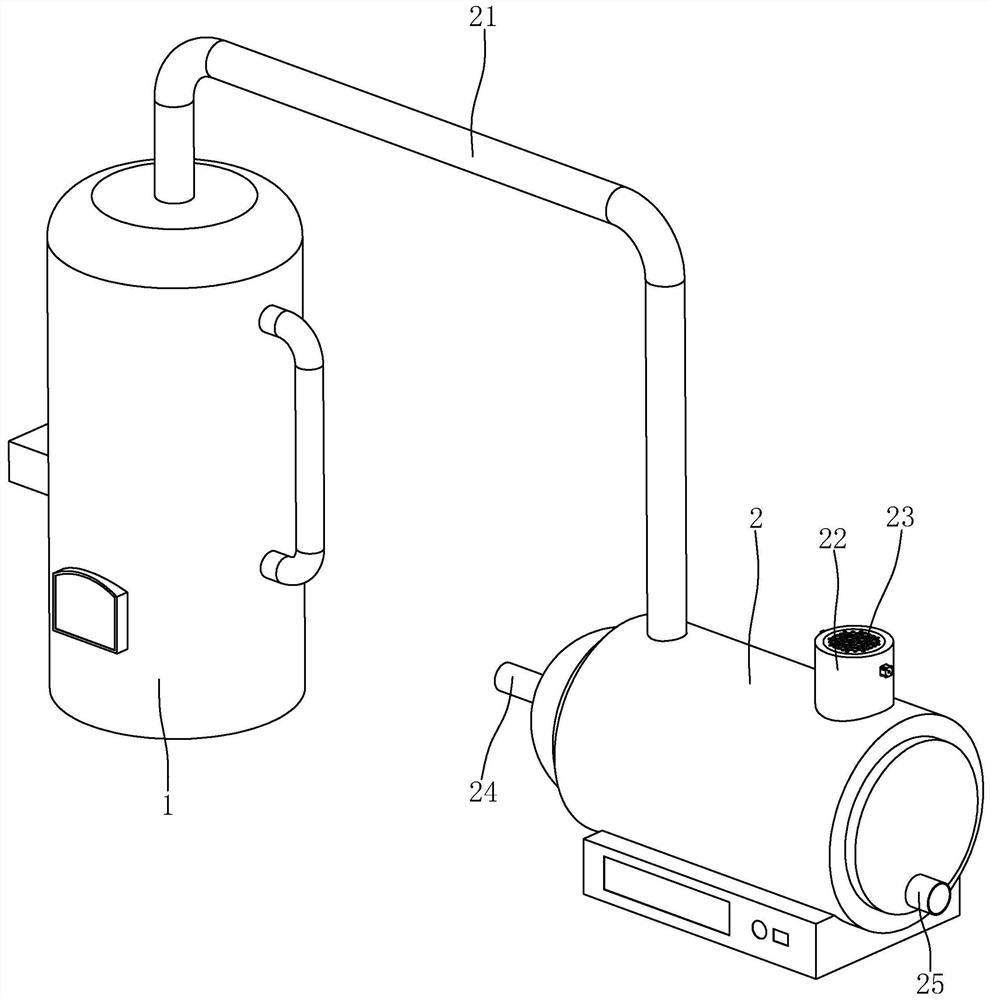

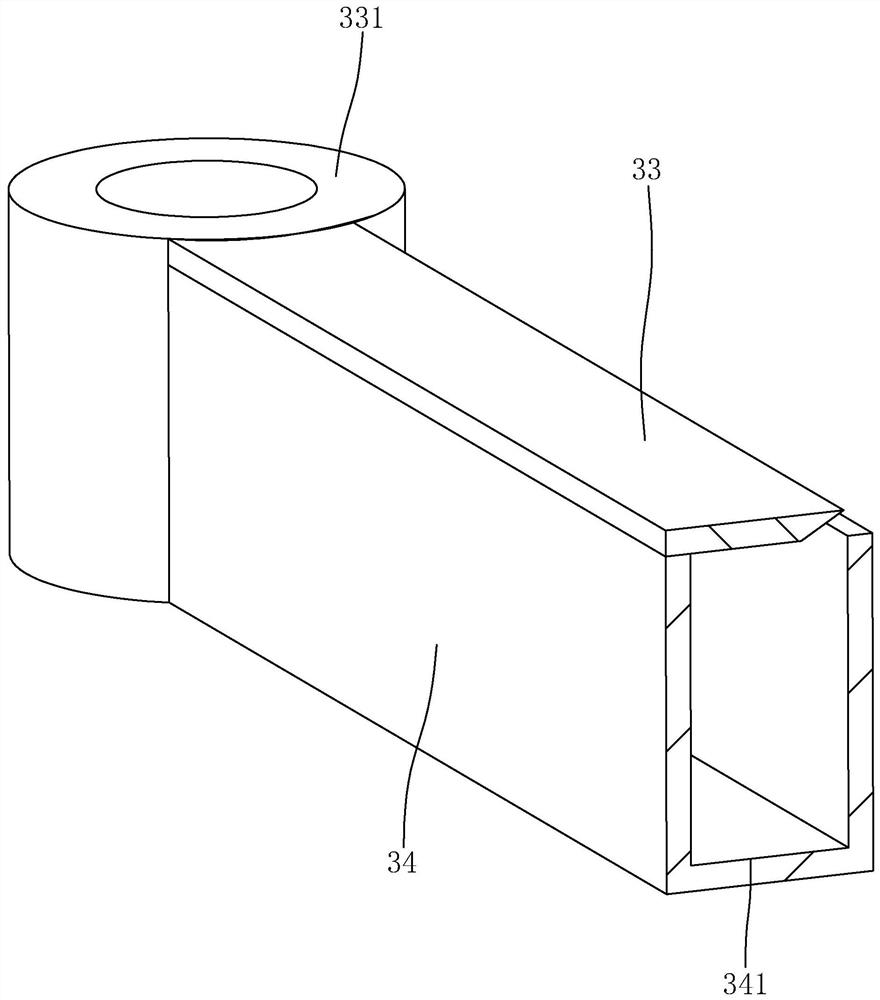

[0033] The embodiment of the present application discloses a hot water recirculation system for flue gas waste heat recovery. refer to figure 1 with figure 2 , the hot water recirculation system for flue gas waste heat recovery includes a boiler body 1 and a flue gas waste heat recovery shell 2; The top of the body 2 is fixedly connected with an outlet pipe 22; the end wall of the flue gas waste heat recovery casing 2 facing the boiler body 1 is fixedly connected with a water inlet pipe 24, and the water inlet pipe 24 is connected with the water tank, and the flue gas waste heat recovery casing 2 is far away from the boiler A water outlet pipe 25 is fixedly connected to the end wall of one end of the body 1; a filter sheet 23 is arranged horizontally at the nozzle of the air outlet pipe 22, and the filter sheet 23 can filter impurities in the flue gas; a cleaning component 3 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com