Anti-blocking drainage device for thoracic surgery department

A thoracic surgery and anti-blocking technology, applied in the direction of suction equipment, etc., can solve the problems of not being able to handle gas and liquid separately, increase patient pain, and reduce the practicability of the device, so as to achieve simple structure and operation, reduce labor intensity, and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1:

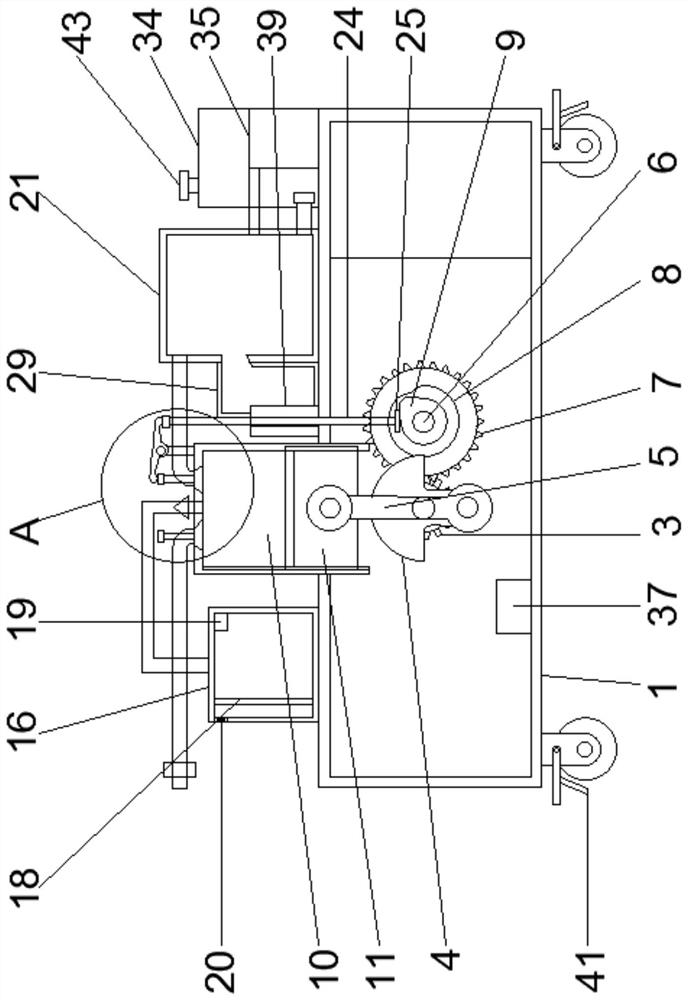

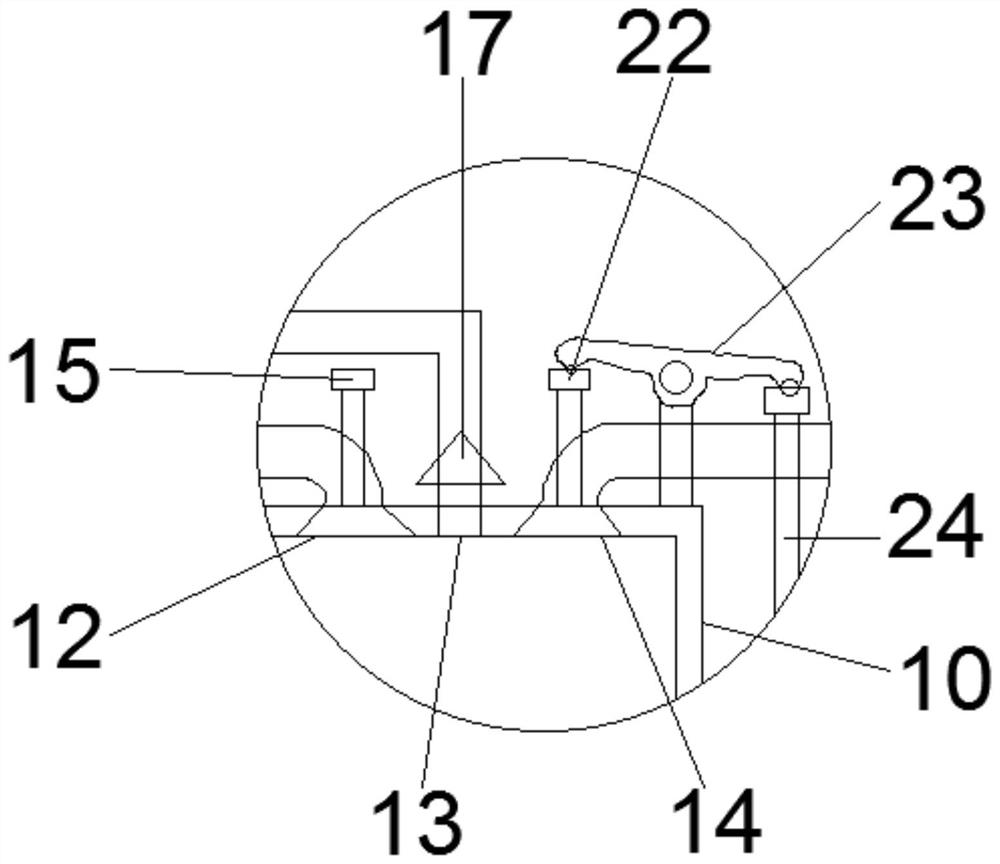

[0029] see Figure 1-8, according to an embodiment of the present invention, an anti-blocking and drainage device for thoracic surgery includes a workbench 1, a first motor 2 is fixed on one side of the workbench 1, and the rotating shaft of the first motor 2 extends into the workbench In the table 1, a first gear 3 is fixedly sleeved in the middle of the rotating shaft of the first motor 2, and a first cam 4 is fixed at one end of the first motor 2. The lower end of the first cam 4 passes through the first gear. The bearing is provided with a connecting rod 5, and a rotating shaft 6 matching the first motor 2 is embedded on one side of the worktable 1 through a second bearing. The middle of the rotating shaft 6 is fixedly sleeved with the first The second gear 7 matched with the gear 3, the first gear 3 and the second gear 7 mesh with each other, a turntable 8 is fixedly sleeved on one side of the rotating shaft 6, and one side of the rotating shaft 6 is ...

Example Embodiment

[0031] Embodiment 2:

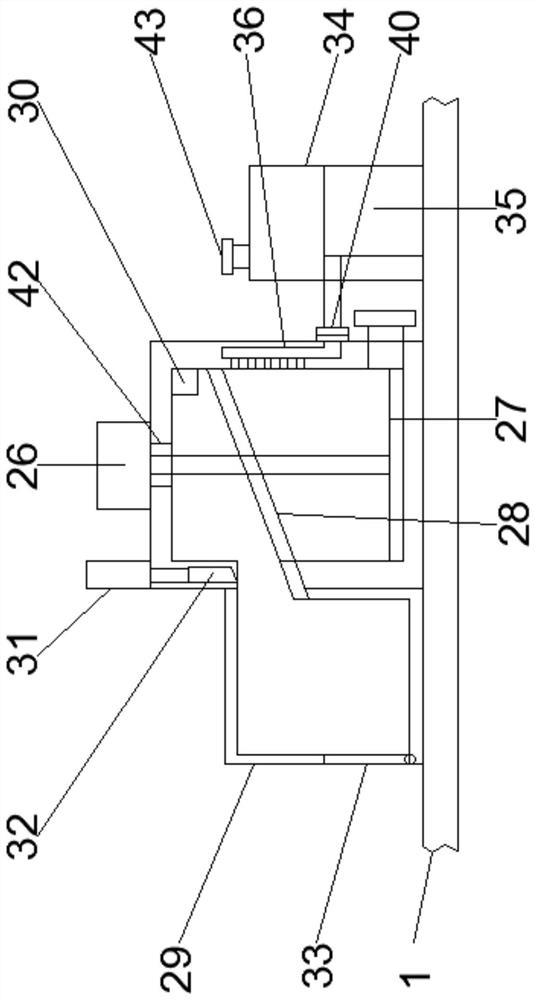

[0032] see Figure 1-4 and Figure 8 , for the sliding sleeve, the upper end of the worktable 1 is fixedly provided with a sliding sleeve 39 matching the sliding rod 24, the rod passes through the sliding sleeve 39, and for the flange, the water pipe passes through the method The flange 40 is connected to the pipe 36 .

[0033] Through the above solution of the present invention, by arranging the sliding sleeve 39 and the flange 40, the movement trajectory of the sliding rod 24 can be easily fixed, and the connection and disassembly of the water pipe and the pipeline 36 can be facilitated.

Example Embodiment

[0034] Embodiment three:

[0035] see Figure 1-4 , for the universal wheel, the four corners of the lower end of the worktable 1 are fixed with universal wheels 41, for the sealing sleeve, the upper end of the push plate 11 is fixedly provided with a sealing sleeve 42, and the upper end of the liquid collecting tank 21 is fixed with a sealing sleeve 42. A sealing sleeve 42 matching the second motor 26 is fixedly provided.

[0036] Through the above solution of the present invention, by providing the universal wheel 41 and the sealing sleeve 42 , the moving device can be facilitated, and the pumping box 10 and the liquid collecting box 21 can be easily sealed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap