Corrugated pipe group cleaning device

A technology of cleaning device and bellows, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low disassembly and cleaning efficiency, inconvenient disassembly, and inconvenient disassembly of bellows, and achieves convenient disassembly and cleaning. Replacement, cleaning effect is good, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

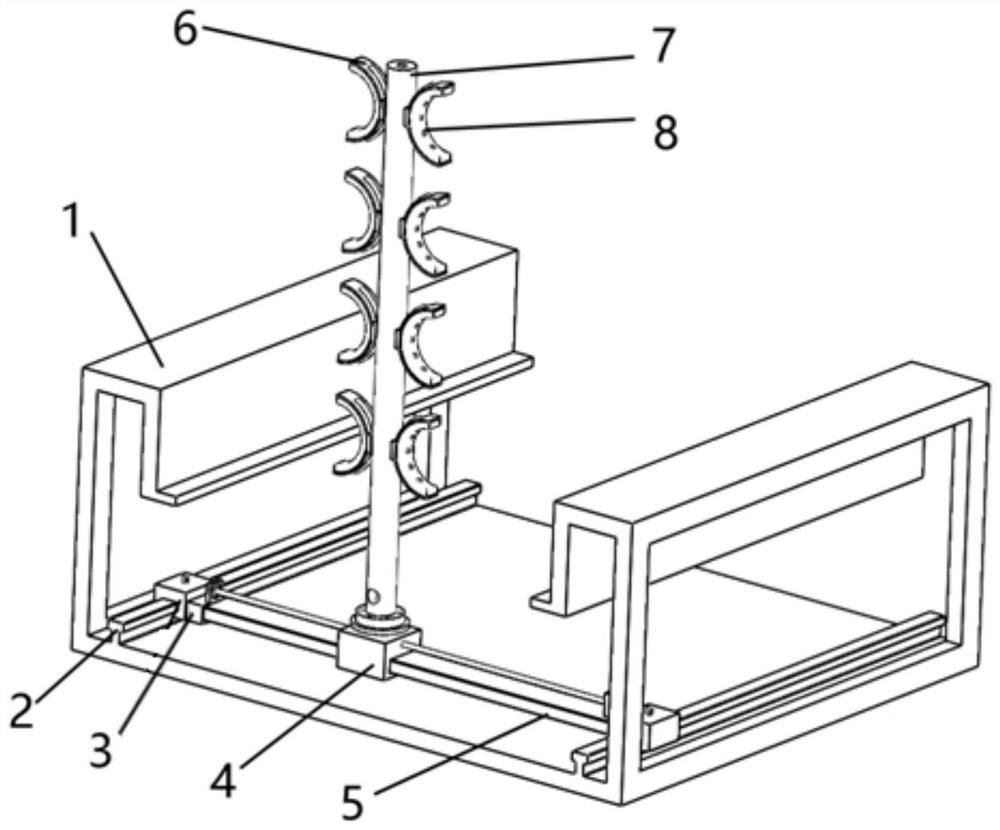

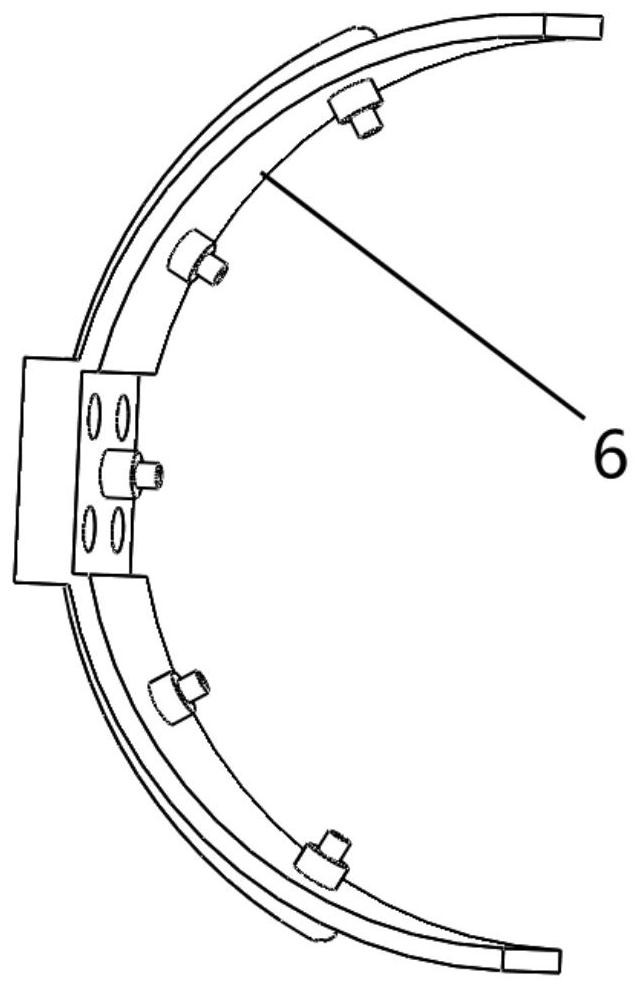

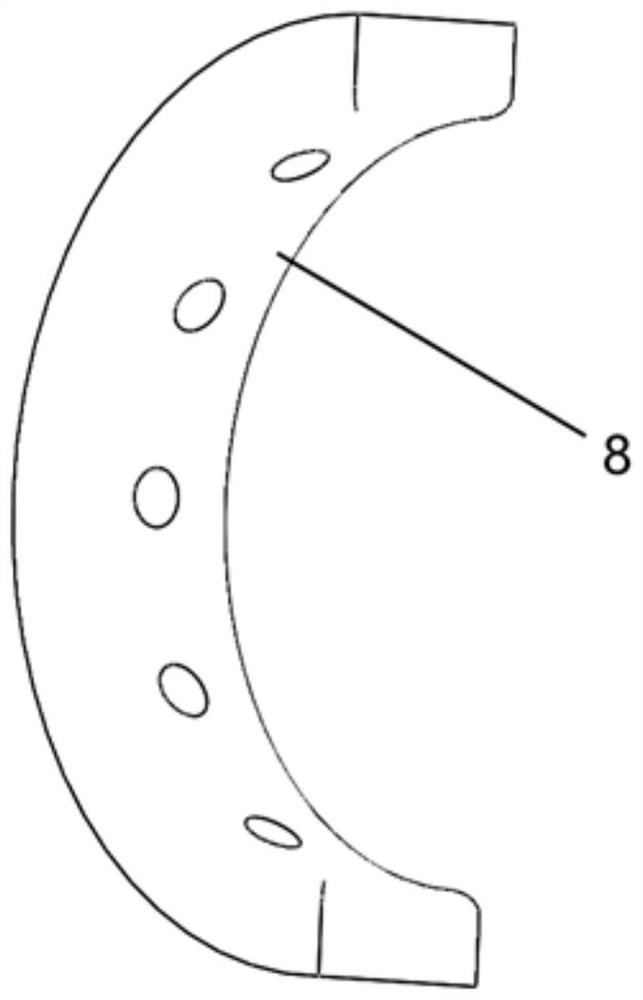

[0032] see Figure 1-10 , a bellows group cleaning device, suitable for cleaning the heat exchange core of a smoke furnace waste heat recovery device with 16 bellows 14 arranged in a 4X4 rule, including a base 1, a base slide rail 2, a cleaning slide rail cover 3, a rotating slide Block 4, cleaning slide rail 5, cleaning brush holder 6, stand 7, cleaning sponge 8, left butterfly bolt 9a, right butterfly bolt 9b, motor 10, bearing 11, screw rod 12, left end cover 13, bellows 14, right end Cover 15, base slide rails 2 are arranged on both sides of the bottom surface of the base 1, and a base slider is provided on each base slide rail 2, a cleaning slide rail cover 3 is arranged on one side of the base slider, and a cleaning slide rail cover 3 is arranged on the other side of the base slider. The cleaning slide rail 5 is provided, and the cleaning slide rail cover 3 is mortised and connected with the base slide rail 2 through the base slide block after tenon joint, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com