Method and system for generating vacuum cup based on vacuum brazing furnace

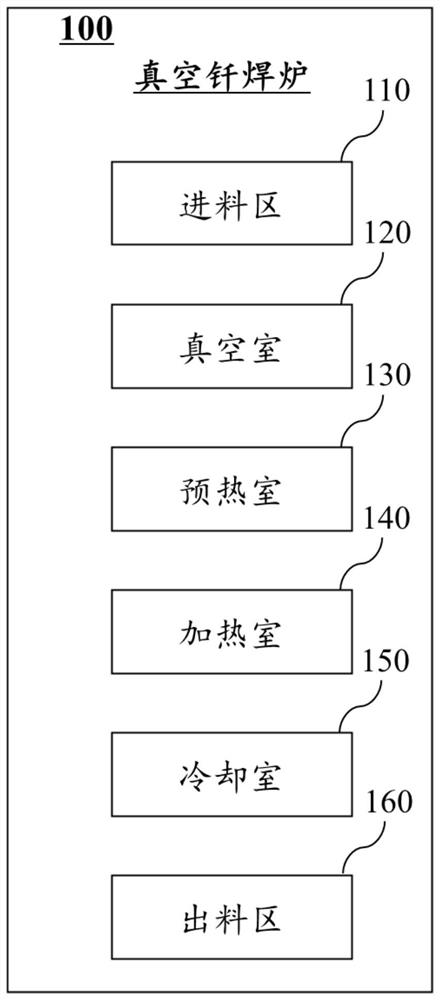

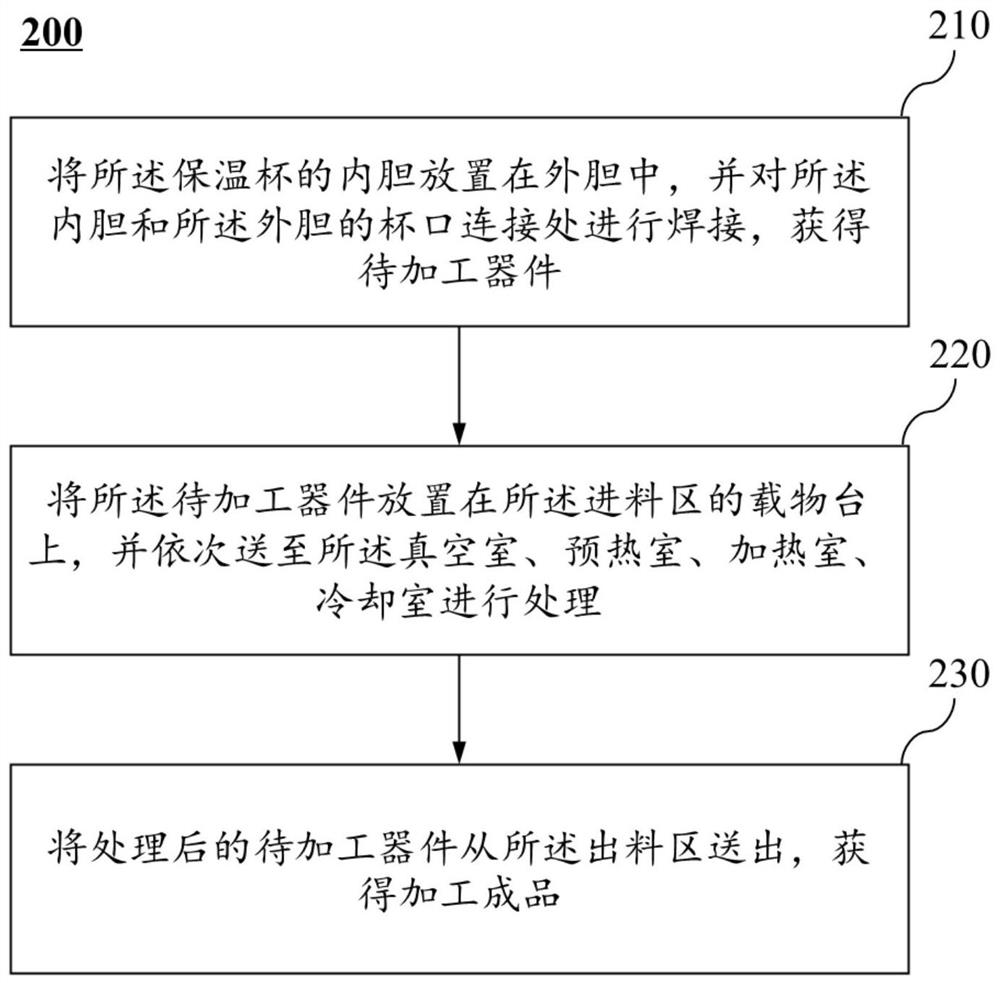

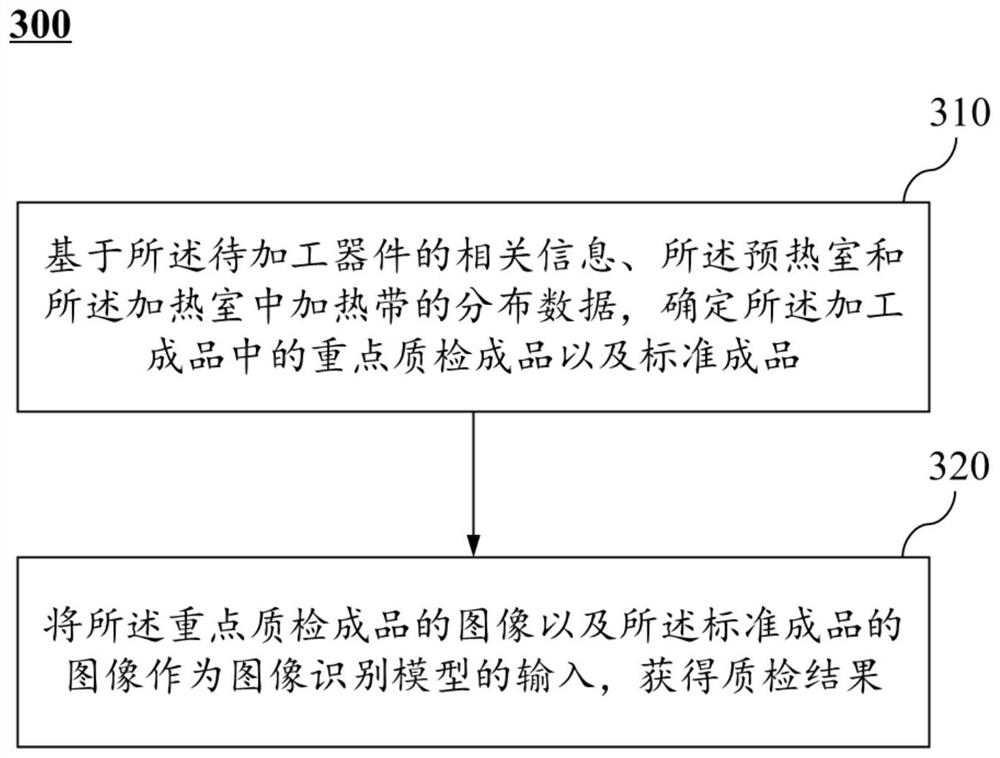

A technology for vacuum brazing furnaces and thermos cups, which is applied to welding equipment, hollow objects, manufacturing tools, etc., and can solve problems such as difficulty in ensuring the quality of thermos cups and different production process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to more clearly illustrate the technical solutions of the embodiments of the present specification, the following briefly introduces the drawings that need to be used in the description of the embodiments. Apparently, the accompanying drawings in the following description are only some examples or embodiments of this specification, and those skilled in the art can also apply this specification to other similar scenarios. Unless otherwise apparent from context or otherwise indicated, like reference numerals in the figures represent like structures or operations.

[0017] It should be understood that "system", "device", "unit" and / or "module" as used herein is a method for distinguishing different components, elements, parts, parts or assemblies of different levels. However, the words may be replaced by other expressions if other words can achieve the same purpose.

[0018] As indicated in the specification and claims, the words "a", "an", "an" and / or "the" are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com