Machine tool chip coiling device for machining

A technology of machining and machine tools, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems affecting the surface roughness of the workpiece, reduce the processing efficiency, increase the auxiliary time, etc., to improve the processing efficiency and processing. Quality, economic cost reduction, effect of reducing auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

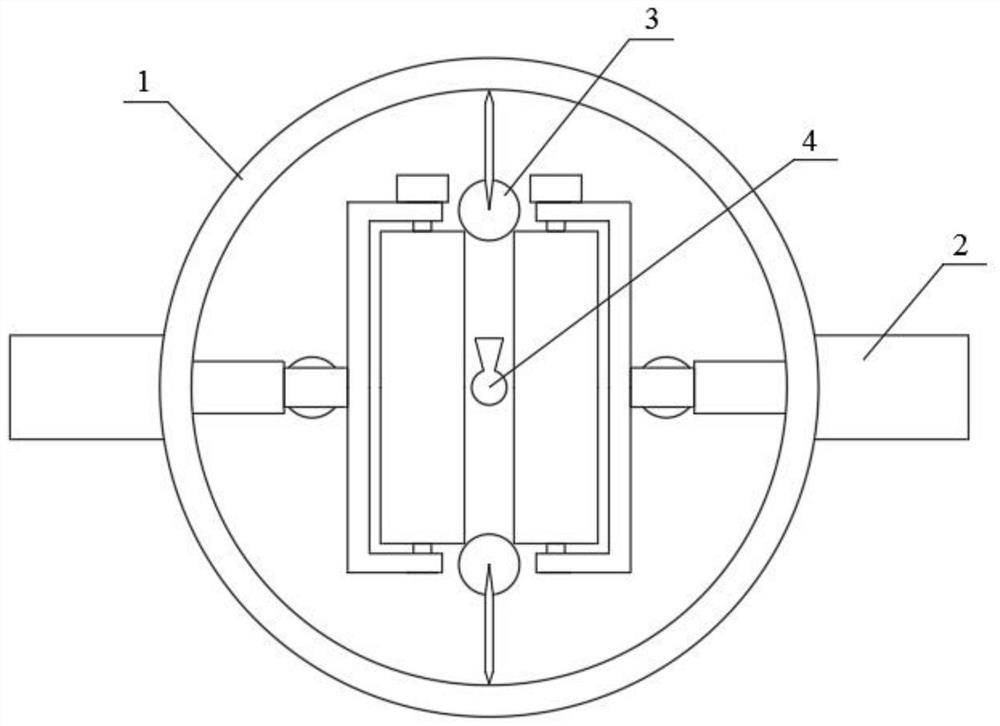

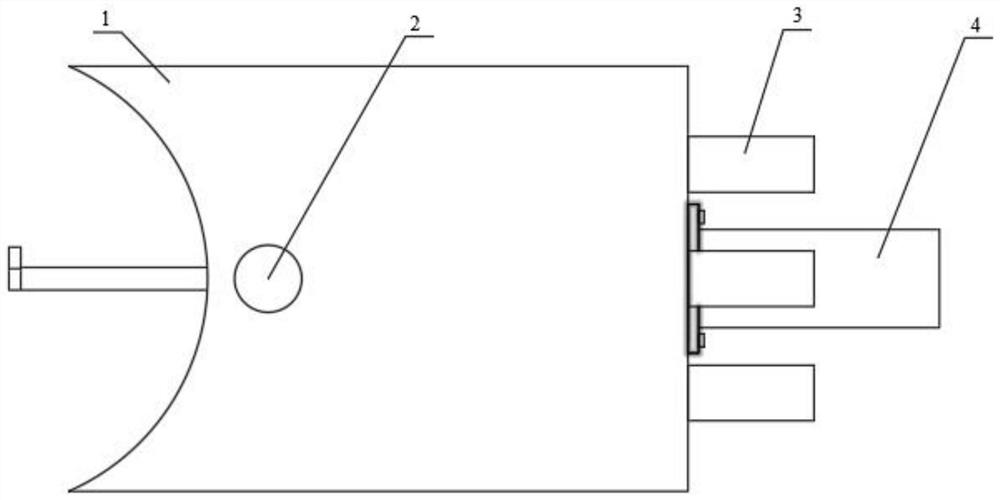

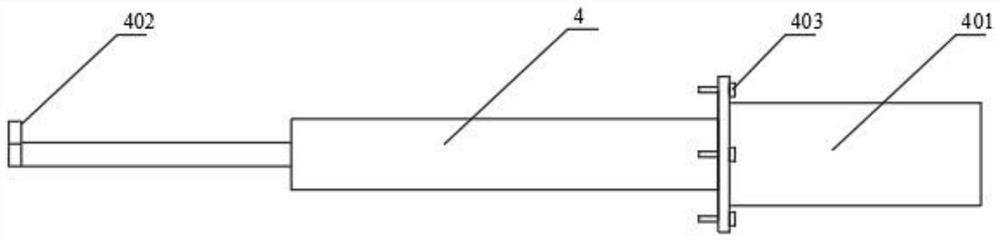

[0037] A machine chip rolling device for machining, such as figure 1 and figure 2 As shown, its structure includes a cylinder body 1 with a closed end. The closed end of the cylinder body 1 is provided with a chip hook assembly 4. The chip hook assembly 4 is used to hook processing chips and pull them into the cylinder body 1. A conveying assembly 2 is arranged on the circumferential side wall of the cylinder 1, and the conveying assembly 2 is used to feed the processing chips drawn into the cylinder 1 to the closed end, and a debris assembly 3 is arranged on the closed end, and the debris assembly 3 is used for Breaks up the machining chips fed into the closed end.

[0038] In use, the machine tool chip rolling device is installed on the side of the main shaft of the lathe or the turning-milling compound machining center, first use the hook chip assembly 4 to hook the processing chips and pull them into the interior of the cylinder 1, and then use the transmission assembly ...

Embodiment 2

[0048] As a further improvement based on the technical solution of Example 1, in order to facilitate the device to be closer to the position of the processing chips, it is easy to operate, such as figure 2 As shown, on the side of the cylinder body 1 away from the closed end, there is an arc-shaped surface which is convenient for approaching the workpiece.

Embodiment 3

[0050] As a further improved solution based on the technical solution of Example 2, in order to facilitate the export of machining chips and prevent secondary reflections on the surface of the workpiece, a leakage hole is provided on the cylinder 1 to facilitate the export of machining chips.

[0051] The invention provides a machine tool chip rolling device for mechanical processing, which can pull the processing chips into the cylinder and crush the processing chips in the cylinder, thereby preventing the processing chips from being entangled on the workpiece or the turning tool and scratching the machine tool. The surface of the workpiece affects the surface roughness of the workpiece. The invention reduces the auxiliary time of processing, improves the processing efficiency and processing quality, reduces the economic cost of workpieces, has strong practicability, and is worth popularizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com