Battery replacing station and battery replacing method of battery replacing station

A technology of power exchange station and power exchange method, applied in the field of power exchange of electric working machines, can solve problems such as low power exchange efficiency, and achieve the effects of reducing waiting time, improving power exchange efficiency and operation efficiency, and shortening power exchange time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

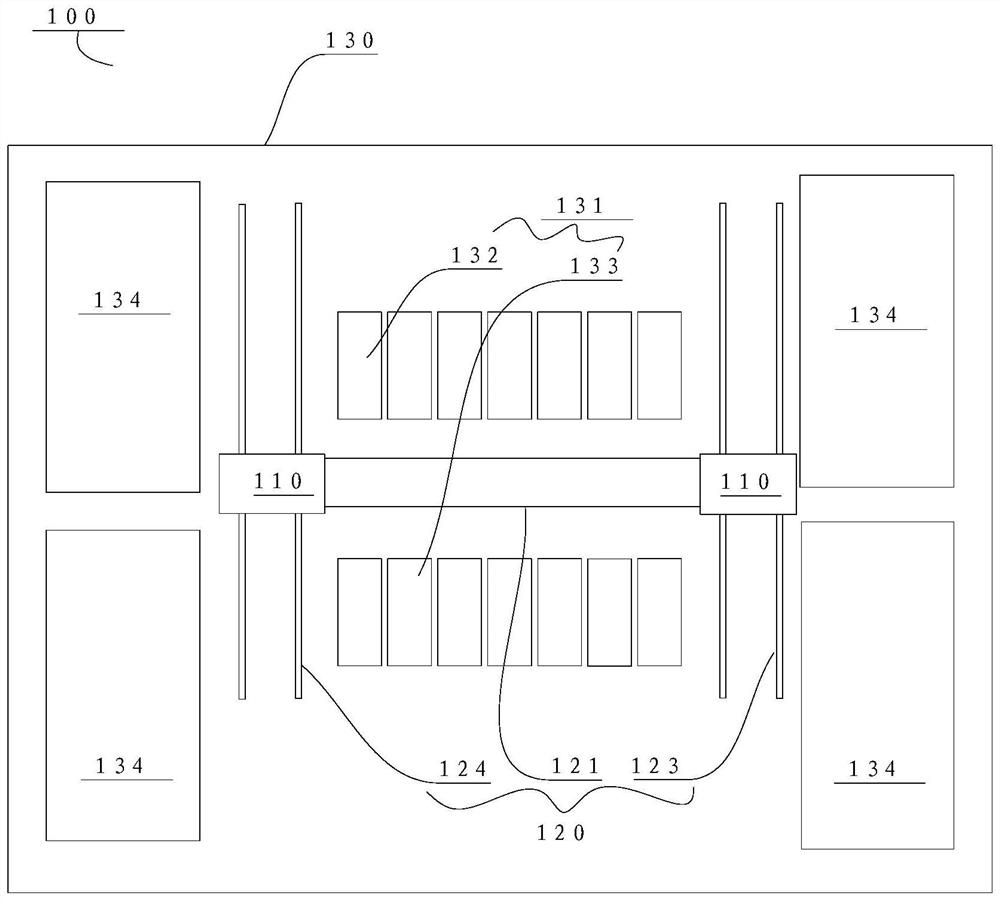

[0062] like figure 1 As shown, in this embodiment, the power exchange station 100 includes a power exchange platform 130 , a battery compartment and two battery transport devices 110 . Here, the battery transport device 110 is an RGV cart.

[0063] The power exchange platform 130 is provided with a first storage area 132 , a second storage area 133 and four power exchange areas 134 . The power exchange platform 130 is further provided with a track 120 , the track 120 is a linear double track structure, and the track 120 includes a first track 121 , a second track 122 and a third track 123 .

[0064] The first rail 121 , the second rail 122 and the third rail 123 are arranged in an I-shape, and the second rail 122 and the third rail 123 are parallel to each other and spaced apart from each other. The first rail 121 is connected between the second rail 122 and the third rail 123 , and the first rail 121 and the second rail 122 and the third rail 123 are all vertical.

[0065]...

Embodiment 2

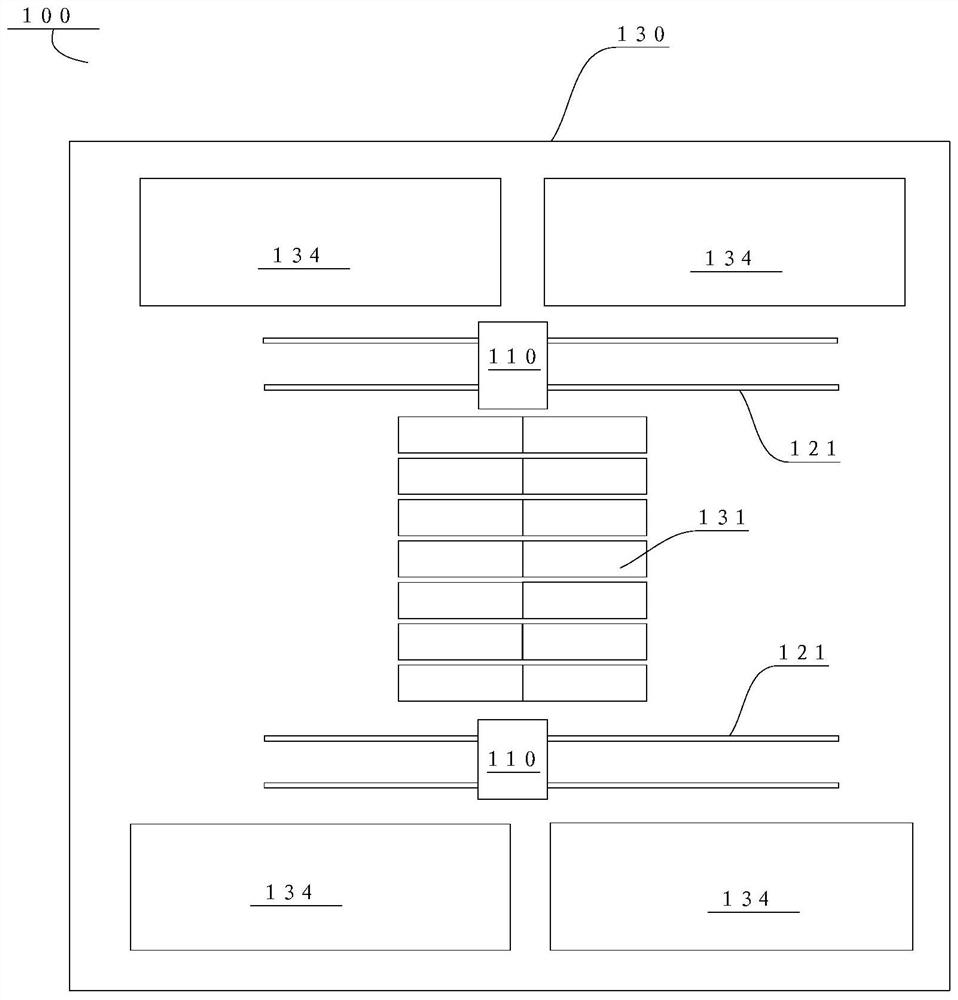

[0069] like figure 2 As shown, in this embodiment, the battery swap station 100 includes a battery swap platform 130 , a battery compartment and two battery transport devices 110 .

[0070] Wherein, the battery compartment is located at the middle position of the battery exchange platform 130 . There are also two parallel rails 120 on the power exchange platform 130 , and each rail 120 has a linear double-rail structure. One of the tracks 120 is located on one side of the battery compartment, and the other track 120 is located on the other side of the battery compartment.

[0071] Further, four battery swapping areas 134 are provided on the battery swapping platform 130 , and one working machine can be parked in each battery swapping area 134 . Two of the four power exchange areas 134 are spaced apart along the extension direction of one of the rails 120, and the two power exchange areas 134 are located on the side of the rail 120 away from the battery compartment; the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com