Construction elevator

A hoist and lifting plate technology, which is applied in the direction of hoisting devices, lifting frames, mechanical equipment, etc., can solve the problems of small area of force, the inability of grooves to play a role in limiting positions, and the inconvenience of construction personnel taking off pipes, etc., to ensure that The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

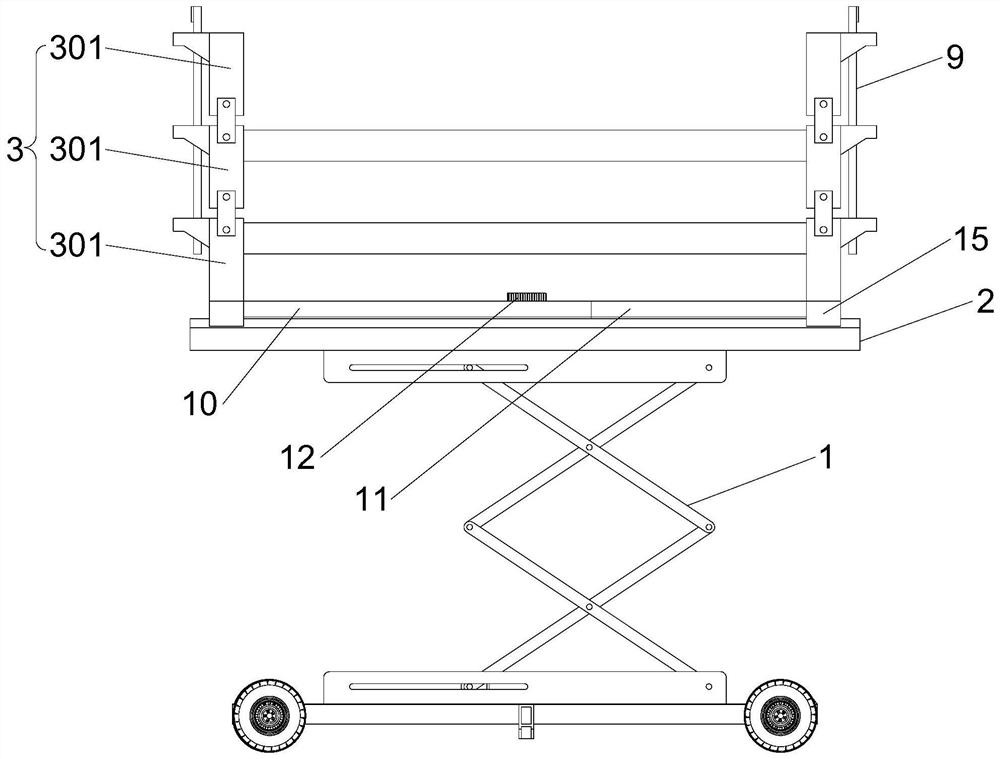

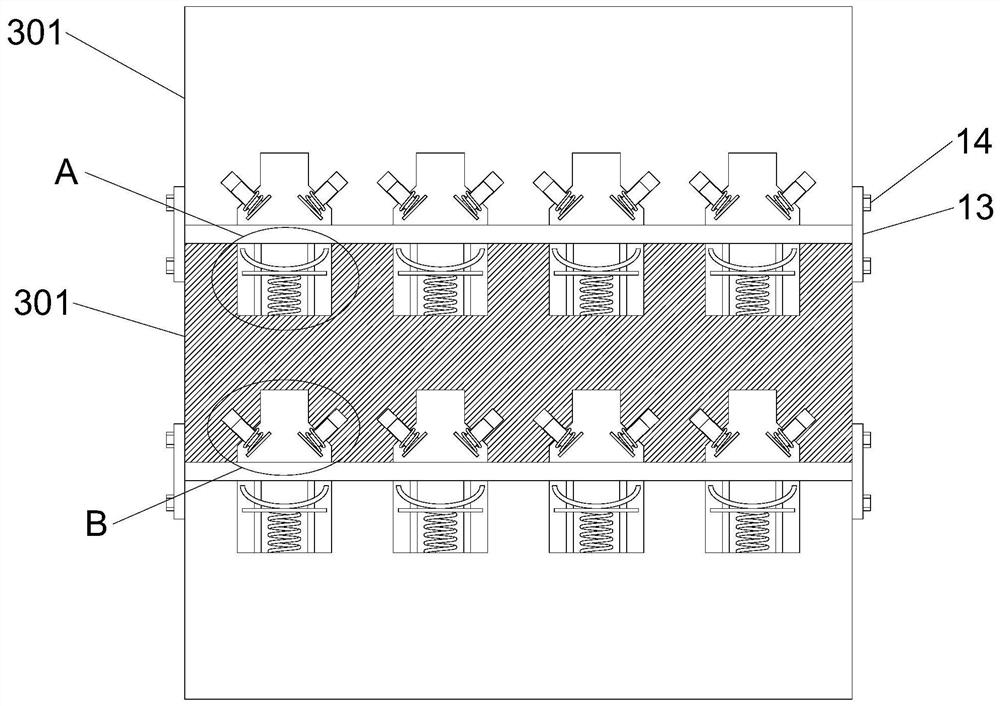

[0035]The construction hoist of the present invention includes a scissor hoist 1, the upper end of the scissor hoist 1 is provided with a placement plate 2, and the upper end of the placement plate 2 is provided with two symmetrical side protection units 3, and the side protection unit 3 includes a plurality of The positioning plates 301 stacked in the vertical direction are hingedly connected between adjacent positioning plates 301, the positioning plate 301 at the top can be turned outward relative to the positioning plate 301 at the bottom, and the upper end of any positioning plate 301 is provided with a first groove 5. An elastic support assembly 4 is provided in the first groove 5, a second groove 6 is provided at the lower end of the positioning plate 301, and an elastic pressing assembly 7 is arranged in the second groove 6, and the elastic pressing assembly 7 located on the upper positioning plate 301 The tightening assembly 7 can cooperate with the elastic support ass...

Embodiment 2

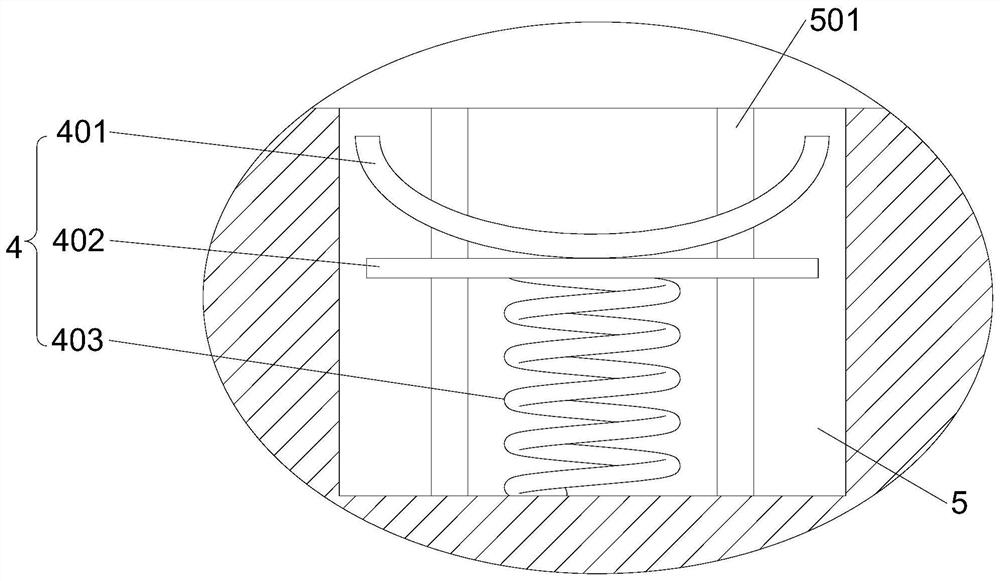

[0038] This embodiment is further optimized on the basis of Embodiment 1 as follows: the elastic support assembly 4 includes a support plate 401, a lift plate 402 and a buffer spring 403, the upper end surface of the support plate 401 is an arc surface, and the lift plate 402 is arranged on the support plate At the lower end of the plate 401 , the buffer spring 403 is located between the support plate 401 and the bottom wall of the first groove 5 . The side wall of the first groove 5 is provided with a chute 501 along the vertical direction, the upper end of the chute 501 runs through the positioning plate 301, and the side wall of the lifting plate 402 is provided with a slide block 502 that is compatible with the chute 501. The cross-sectional shape of the slider 502 is dovetail or T-shaped, and the sliding groove 501 is a dovetail or T-shaped groove adapted to the slider 502 .

[0039] After adopting the above technical solution: a buffer spring 403 is provided under the el...

Embodiment 3

[0041] This embodiment is further optimized on the basis of Embodiment 1 as follows: the elastic pressing assembly 7 includes two symmetrically arranged pressing plates 701, and the distance between the two pressing plates 701 gradually increases from top to bottom , the inner side of the pressing plate 701 is provided with a guide post 703, the axis of the guide post 703 is perpendicular to the plane where the pressing plate 701 is located, the inner wall of the second groove 6 is provided with a guide groove 704 that is compatible with the guide post 703, and the guide A compression spring 702 is sheathed on the column 703 , and the compression spring 702 is located between the compression plate 701 and the outer wall of the guide groove 704 .

[0042] After adopting the above technical solution: the two pressing plates 701 of the elastic pressing assembly 7 are arranged symmetrically, and the combination of the two pressing plates 701 forms a figure-eight shape. The pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com