Automatic chemical copper adding device

An automatic adding and chemical copper technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems that the charging frame cannot be automatically pushed out, the waste of chemical copper resources, and the collection efficiency of chemical copper solution are reduced. , to facilitate collection, improve efficiency and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

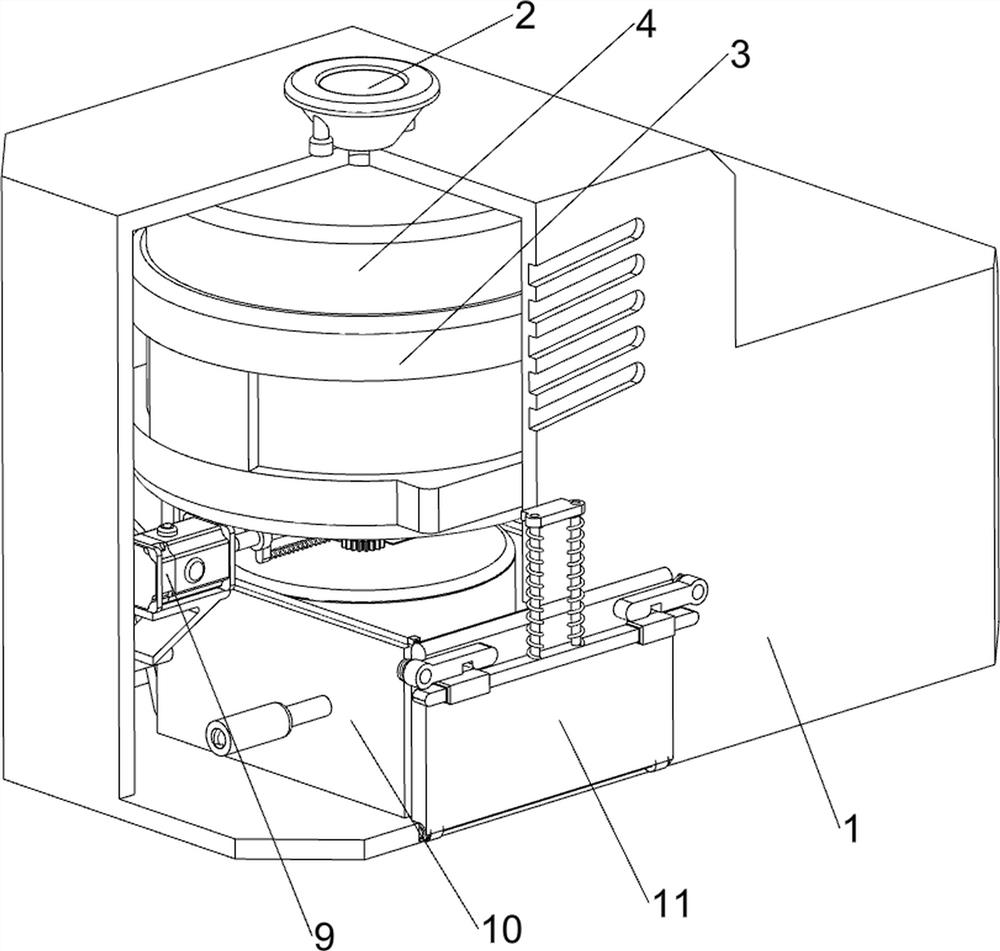

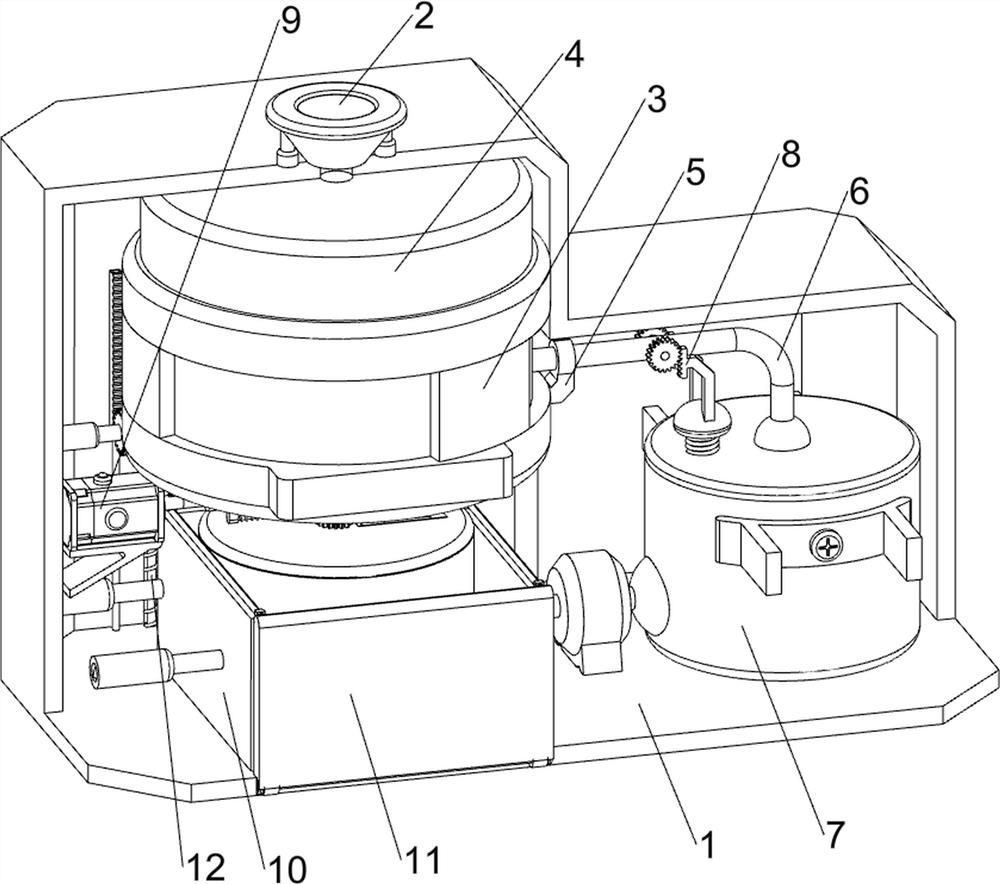

[0037] A chemical copper automatic adding device, such as Figure 1-Figure 8 As shown, it includes a casing 1, a cover 2, a support frame 3, a storage tank 4, a first mounting seat 5, a one-way valve 6, a placement mechanism 7 and a feeding mechanism 8, and a support frame 3 is fixedly connected to the upper left side of the casing 1. A storage tank 4 is installed on the inner side of the support frame 3, a cover 2 is slidably connected between the storage tank 4 and the top left side of the housing 1, a first mounting seat 5 is fixedly connected to the lower right side of the storage tank 4, and a Placement mechanism 7, a one-way valve 6 is connected between the placement mechanism 7 and the storage tank 4, the one-way valve 6 passes through the first installation seat 5, and a feeding mechanism 8 is installed between the placement mechanism 7 and the one-way valve 6.

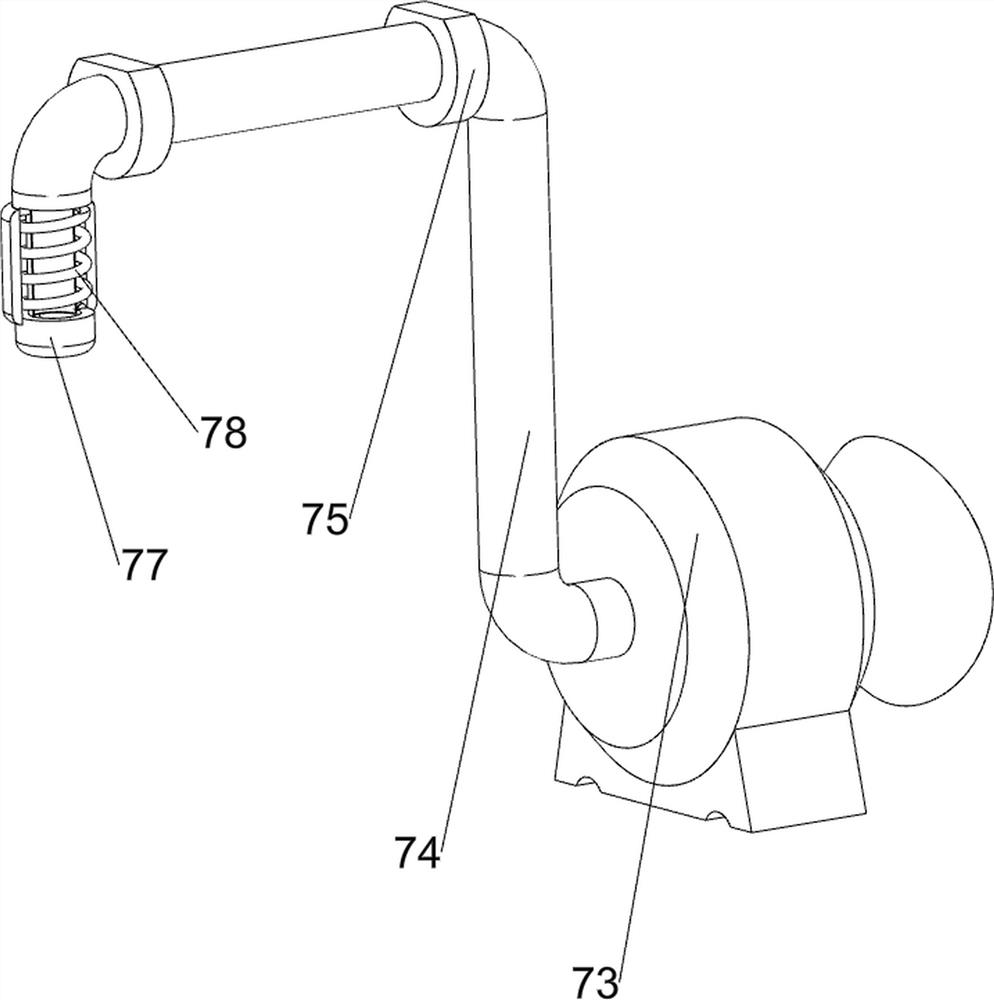

[0038] The placement mechanism 7 includes a bracket 71, a collection tank 72, a filter 73, a conduit 74, a ...

Embodiment 2

[0042] On the basis of Example 1, such as Figure 9-Figure 17 As shown, a stirring assembly 9 is also included, and the stirring assembly 9 includes a servo motor 91, a rotating base 92, a second rotating shaft 93, a bevel gear 94, a third rotating shaft 95 and a stirring rod 96, and the lower left side of the housing 1 is equipped with a servo motor 91, the left side of the bottom of the storage tank 4 is fixedly connected with a swivel seat 92, the inner side of the swivel seat 92 is rotatably provided with a second rotating shaft 93, the second rotating shaft 93 is connected with the output shaft of the servo motor 91, and the inner lower side of the storage tank 4 is rotatably connected There is a third rotating shaft 95, the third rotating shaft 95 and the second rotating shaft 93 are connected with a bevel gear 94, the bevel gears 94 mesh with each other, and the top of the third rotating shaft 95 is connected with a stirring rod 96.

[0043] Also includes a shock assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com