Waste copper refining device

A technology for copper refining and adjusting device, applied in descaling device, lighting and heating equipment, furnace components, etc., can solve the problems of complicated operation mode, difficult to control the amount of copper material conveyed, and reduce the working efficiency of scrap copper refining, etc. Enhanced sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

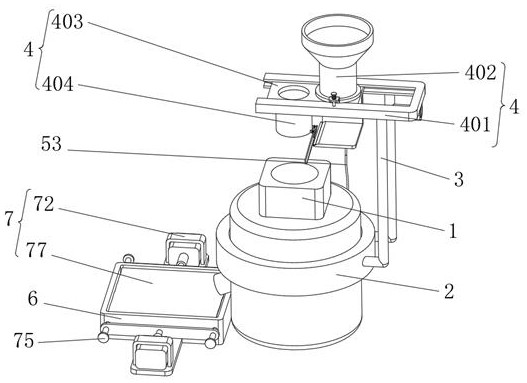

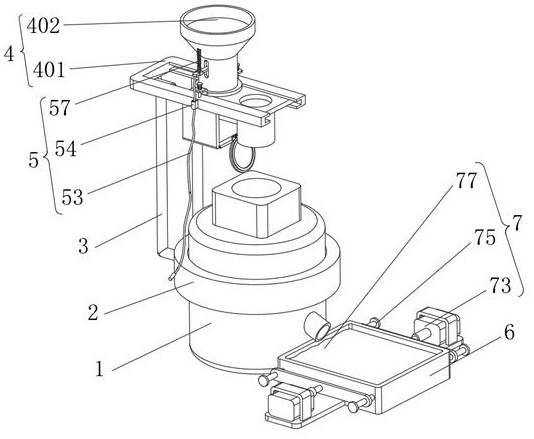

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a scrap copper refining device, comprising a melting furnace 1 and a regulating device 4, the circular arc surface of the melting furnace 1 is fixedly installed with a fixed ring 2, and the circular arc surface of the fixed ring 2 is evenly fixed with two The supporting rod 3 is provided with an adjustment device 4 at one end of the supporting rod 3 away from the fixing ring 2 .

[0031] Let's talk about the concrete setting and effect of its regulating device 4, auxiliary device 5 and knocking device 7 in detail below.

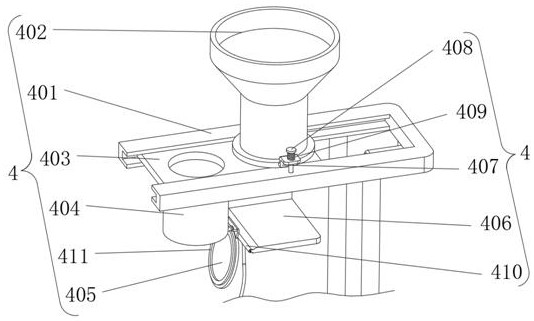

[0032] Such as image 3 and Figure 4As shown, the adjustment device 4 includes a track plate 401, the lower surface of the track plate 401 is fixedly connected with the support rod 3, the track plate 401 is in a "U" shape, and the side of the track plate 401 away from the support bar 3 is clamped with a discharge pipe 402 The inner wall of the track plate 401 is slidably connec...

Embodiment 2

[0038] Embodiment 2, on the basis of embodiment 1, the surface of the feeding pipe 402 is provided with an auxiliary device 5, and the auxiliary device 5 includes a sliding hole 51, and the sliding hole 51 is opened on the surface of the feeding pipe 402, and the inner wall of the sliding hole 51 is rotatably connected There is a rotating plate 52, and the end of the rotating plate 52 away from the inner wall of the slide hole 51 is fixedly connected with a traction rope 53, and the arc surface of the traction rope 53 is slidingly connected with a limit buckle 54, and the surface of the limit buckle 54 is fixedly connected with the track plate 401. The end of the plate 52 away from the traction rope 53 is fixedly connected with a bump 55, the end of the bump 55 away from the rotating plate 52 is pointed, the bumps 55 are evenly distributed on the surface of the rotating plate 52, and the end of the rotating plate 52 close to the pulling rope 53 is slidably connected There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com