Vapor phase epitaxy system and maintenance operation method thereof

A technology of vapor phase epitaxy system and air inlet flange, which is applied in the field of vapor phase epitaxy system and its maintenance operation, can solve the problems of low utilization rate and inconvenient maintenance of large-sized reaction chamber, achieve less dead zone at low temperature, and improve equipment operation. efficiency and yield, and the effect of simplifying the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

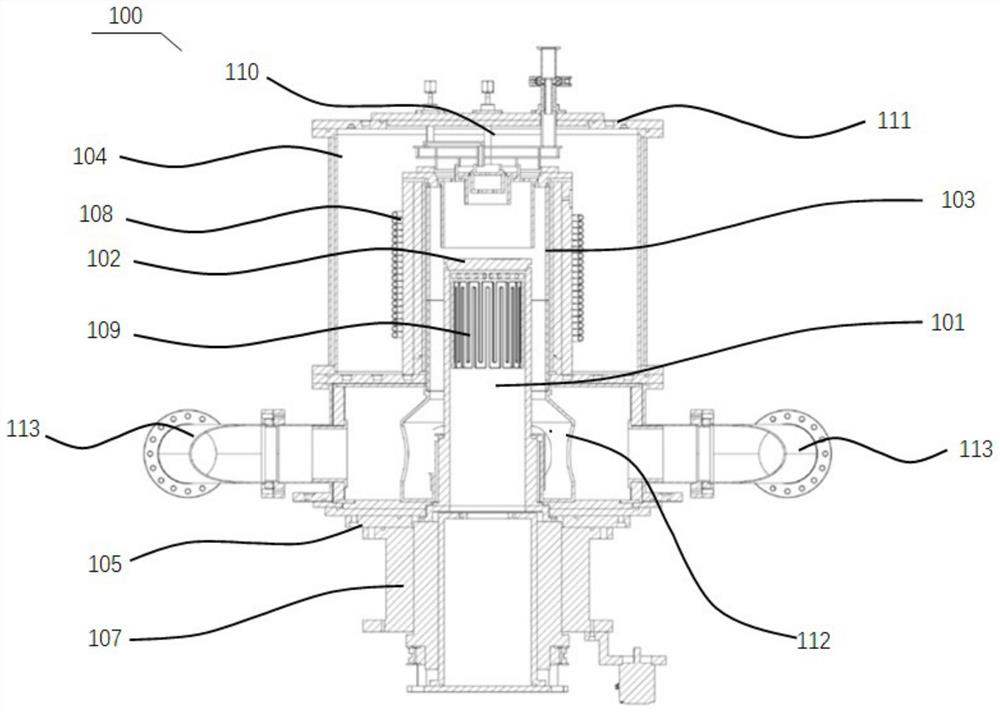

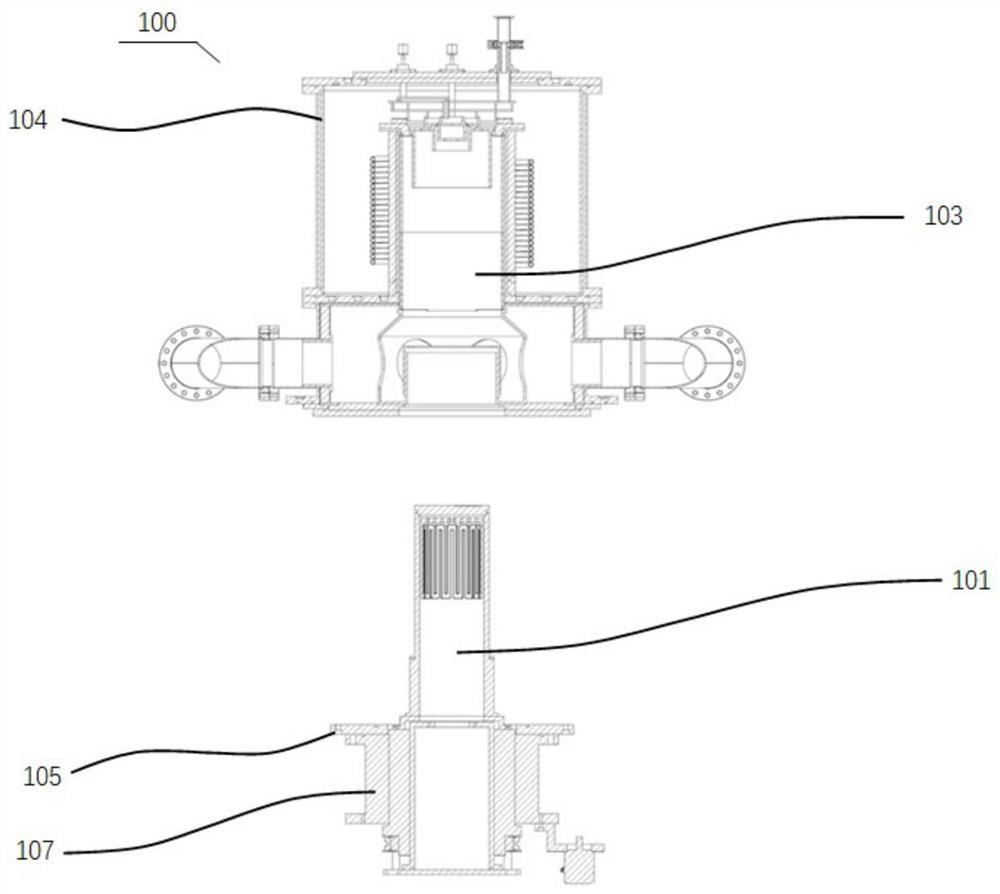

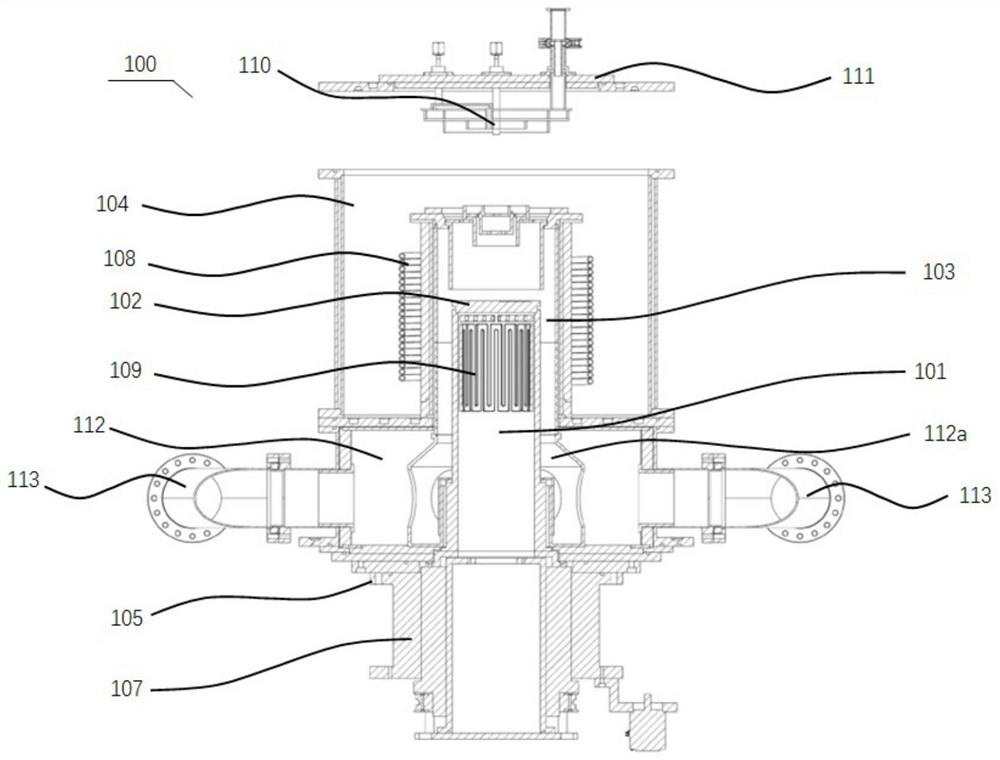

[0050] figure 1A schematic diagram of an exemplary cross-sectional structure of the vapor phase epitaxy system 100 provided in this embodiment is shown. The vapor phase epitaxy system 100 includes a carrier plate support device 101, a cover body 105, a reaction chamber and a top cover assembly; the carrier plate support device 101 is used to support the carrier plate 102 at the top of the carrier plate support device 101, the The carrier support device 101 passes through the cover 105, and the cover 105 is connected to the carrier support device 102; the reaction chamber includes an inner chamber 103 and an outer chamber 104, and the inner chamber 103 is Reaction chamber, the inner chamber 103 is arranged in the outer chamber 104; the top cover assembly is located at one end of the reaction chamber, the top cover assembly includes an air inlet pipeline 110 and an air inlet flange 111, The inlet flange 111 is connected with the outer chamber 104 by a fastening device for seali...

Embodiment 2

[0060] The structure of the vapor phase epitaxy system described in this embodiment is substantially the same as that of the vapor phase epitaxy system 100 described in Embodiment 1. The difference between the two is that in Embodiment 1, only the external heater 108, and in this embodiment, in addition to the external heater 108 in the outer chamber 104, an internal heater 109 is also provided at a position close to the carrier 102 in the carrier support device 101, That is, the vapor phase epitaxy system in this embodiment adopts a double heating system.

[0061] Specifically, please continue to refer to figure 1 . Such as figure 1 As shown, the outer chamber 104 is provided with an external heater 108, and the external heater can be a thermal wall type external heater, located on the outer wall of the inner chamber 103, for heating the inner chamber 103; An internal heater 109 is disposed in the disc supporting device 101 close to the disc 102 . Optionally, the internal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap