Efficient carbon fiber pre-oxidation furnace

A pre-oxidation furnace, carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of unable to effectively adjust the gap between the precursors, unable to change the heating area of the precursors, affecting the preoxidation effect of the precursors, etc. Pre-oxidation effect, high-efficiency pre-oxidation treatment, effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

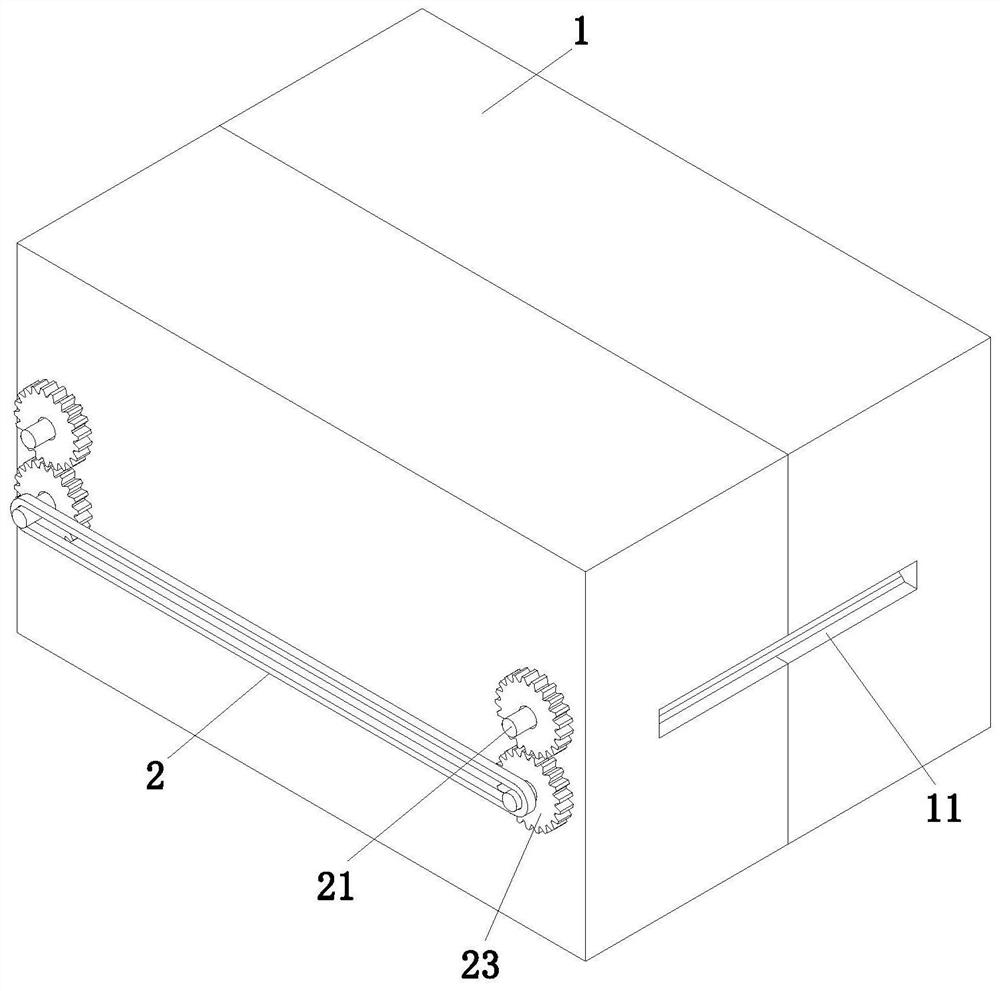

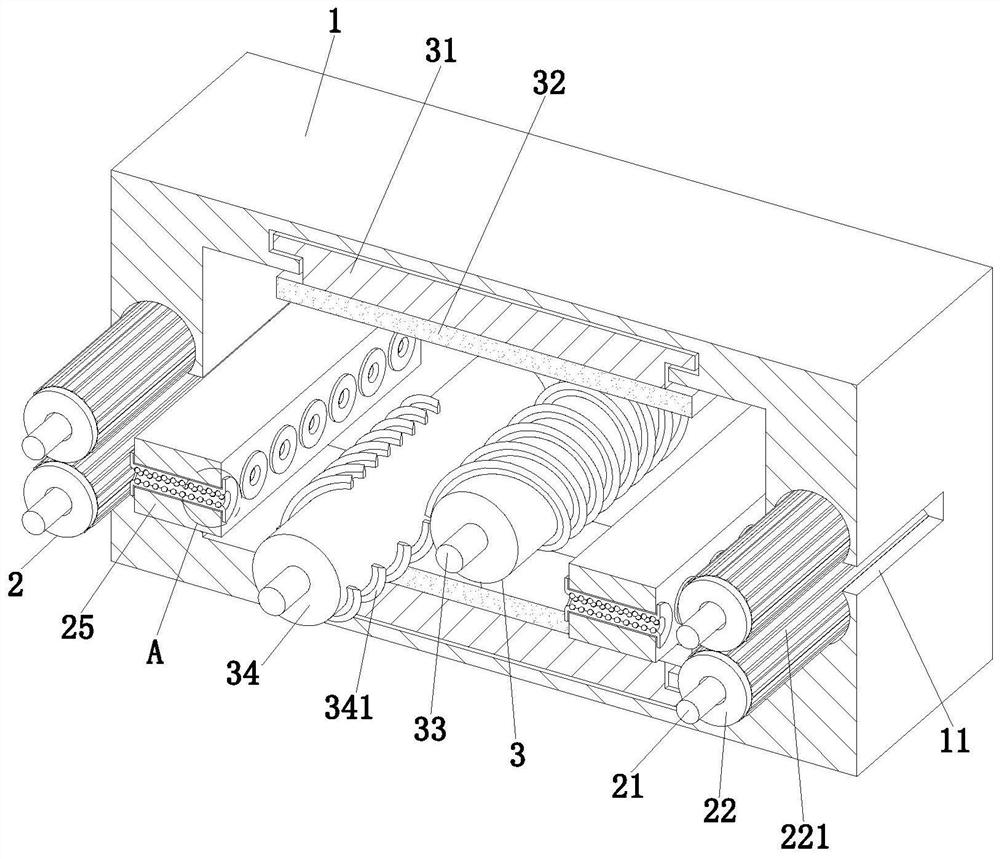

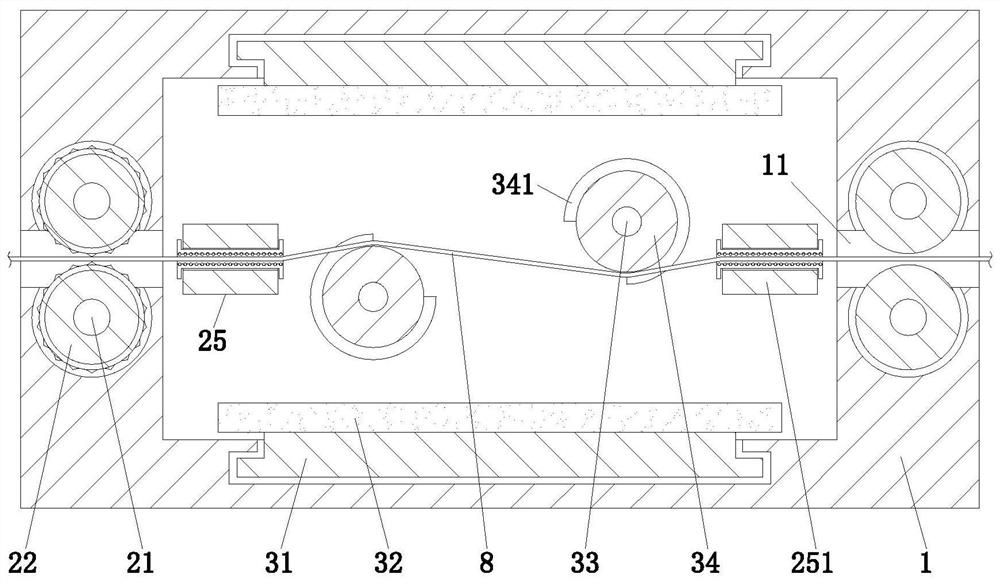

[0031] refer to figure 1 , figure 2 , a carbon fiber high-efficiency pre-oxidation furnace, including a furnace body shell 1, a conveying unit 2 and a pre-oxidation unit 3, the outer wall of the furnace body shell 1 is symmetrically opened with feed holes 11, and the conveying unit 2 is arranged on the furnace body shell 1 , the pre-oxidation unit 3 is installed on the inner wall of the furnace body shell 1, and the furnace body shell 1 is a splicing structure for easy disassembly, which facilitates the installation and replacement of the conveying unit 2 and the pre-oxidation unit 3 .

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5, the conveying unit 2 includes a linkage shaft 21, a transmission roller 22, an execu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com