A caisson construction structure using a connector and its construction method

A construction method and a technology of a connector, which are applied to the construction structure of caissons and its construction field, can solve the problems of grouting body tensile damage, box body damage, caisson bulging, etc., so as to reduce the amount of excavation drainage and improve construction efficiency. quality, the effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

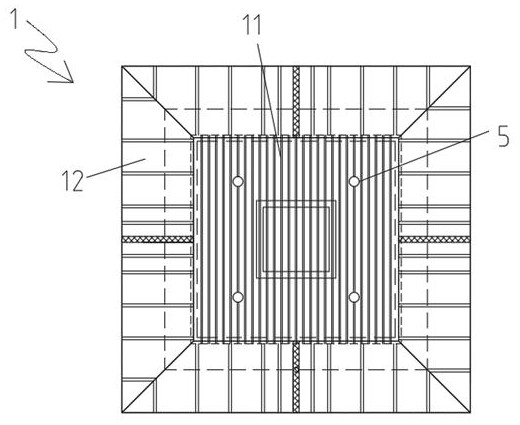

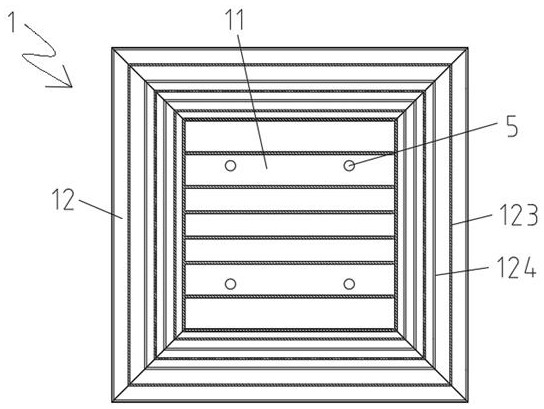

[0041] see Figure 1 to Figure 8 As shown, the first embodiment of the present application provides a construction structure for fixing a caisson 1 by using an anchor rod, including: a pit body 31 , an anti-floating anchor rod 2 and a caisson 1 . The anti-floating anchor rod 2 is fixed in the soil layer at the bottom of the pit body 31 . The caisson 1 is installed in the pit body 31 , and the caisson 1 is connected with the anti-floating anchor rod 2 , and the anti-floating anchor rod 2 defines the position of the caisson 1 . In this application, the anti-floating anchor rod 2 is first constructed, and then the earthwork excavation and the installation of the caisson 1 are carried out. After the caisson 1 is installed in place, the anti-floating anchor rod 2 is welded and connected, and the anti-floating anchor rod 2 is prestressed and tensioned to prevent floating. effect. The pull-out resistance provided by the anti-floating anchor rod 2 in the present application effectiv...

Embodiment 2

[0054] The second embodiment of the present application provides a construction method for fixing the construction structure of the caisson 1 by using an anchor rod in the above-mentioned first embodiment. Specifically, it includes the following steps:

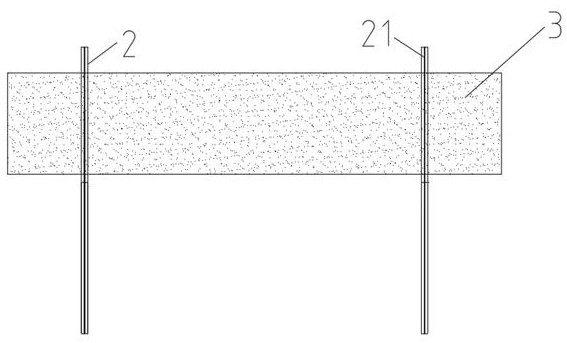

[0055] Step S1, see image 3 As shown, drill holes on the undisturbed soil 3 to install the anti-floating anchor rod 2;

[0056] The top elevation of the undisturbed soil 3 is the bottom elevation of the large surface of the raft foundation 9 , and the anti-floating anchor rod 2 is pre-drilled and grouted on the upper surface of the undisturbed soil 3 . Preferably, two anti-floating anchor rods 2 can be connected to each inclined wall 12 around the installed caisson 1 . The anti-floating anchor rod 2 can use steel strands 21, for example, a locator can be welded every 2.0m, the total length of the anchor rod is 15m, the length of the free end is 5m, the length of the anchoring section is 10m, and the locking value is 300KN. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com