Existing tunnel crossing system based on underground excavation pilot tunnel and jump excavation vertical shaft and construction method

A technology for existing tunnels and shafts, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as environmental damage, uplift deformation, high construction costs, etc., achieve high economic and social benefits, wide application prospects, and facilitate processing The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

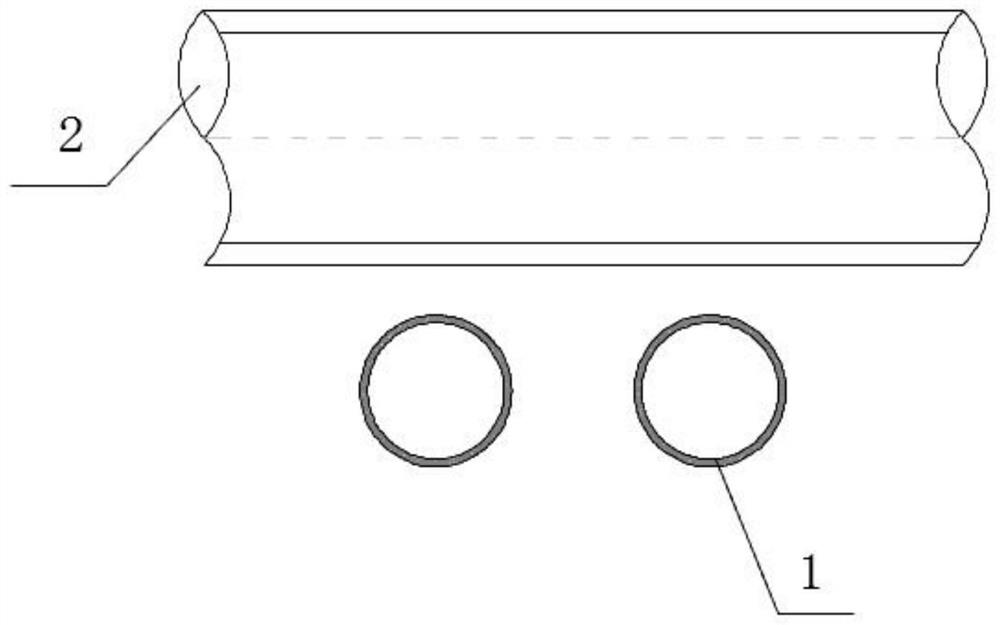

[0038] An existing tunnel spanning system based on underground excavation of pilot tunnels and jump-excavation shafts, including existing tunnel 1 and new tunnel 2; figure 1 As shown in the profile diagram of the existing tunnel spanning the new tunnel (after completion), the new tunnel 2 is set above the existing tunnel 1, and the central axis of the new tunnel 2 is at an angle of 70° to 90° or 20° to the central axis of the existing tunnel 1. ~30 degrees;

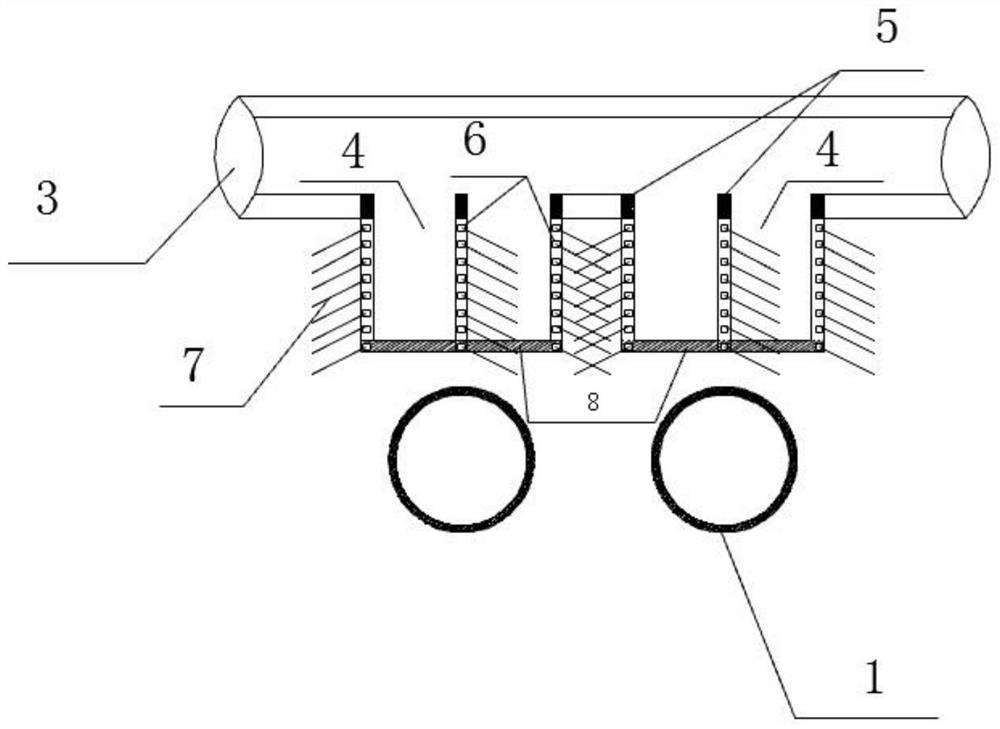

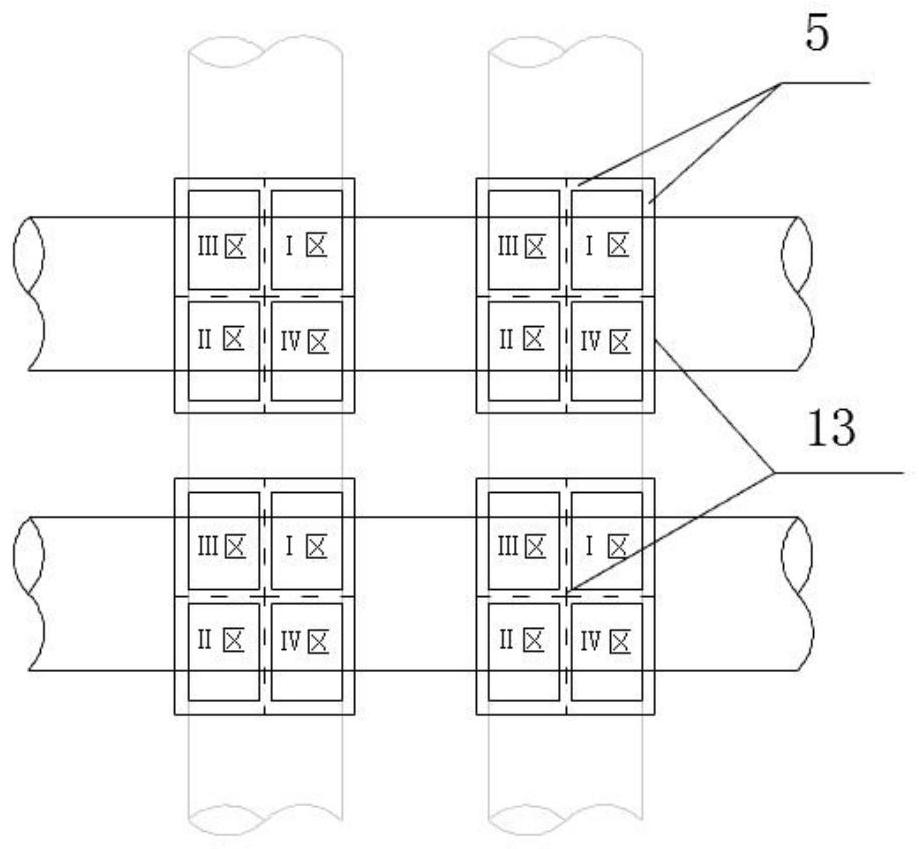

[0039] Such as figure 2 Schematic diagram of the excavation of the longitudinal pilot tunnel in the upper half section of the new tunnel and the vertical shaft in the spanning section, Figure 4 As shown in the cross-sectional diagram of the underground excavation pilot tunnel combined with the vertical shaft crossing the existing line, the area where the newly-built tunnel 2 overlaps with the projection of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com