A Passive Vectoring Flexible Joint Structure for Segmental Lining of Cross-fault Tunnel

A technology of flexible joints and tunnel joints, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of reduced bearing reliability, insufficient deformation capacity, unreliable waterproof measures, etc., to prevent structural relaxation damage and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

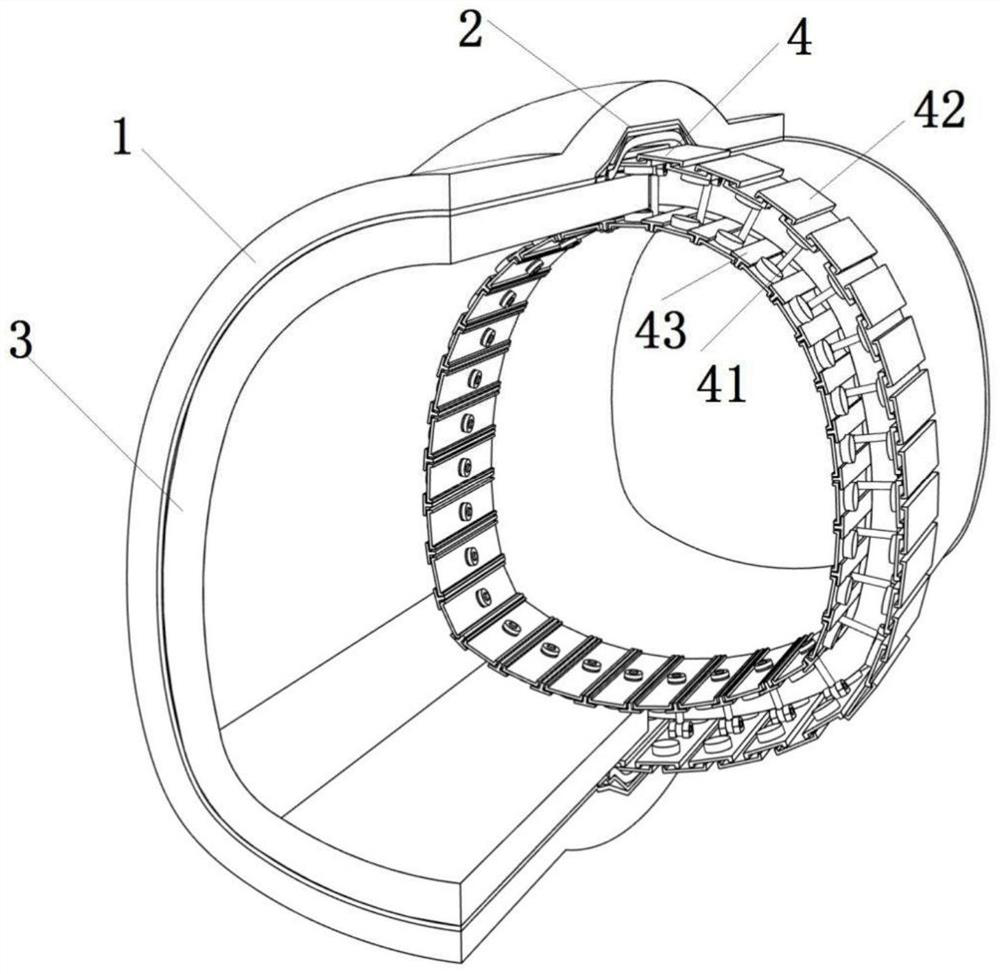

[0032] like Figures 1 to 5 As shown, the passive vector flexible joint structure of the segmental lining of the cross-fault tunnel in this embodiment is suitable for the segmental secondary lining of the cross-fault tunnel. In the cross-fault tunnel, an initial support 1 , a waterproof board 2 and a secondary lining 3 are sequentially arranged along the tunnel section from outside to inside. In this embodiment, the flexible joint structure 4 is arranged between the segmental secondary linings 3 to play a connecting role.

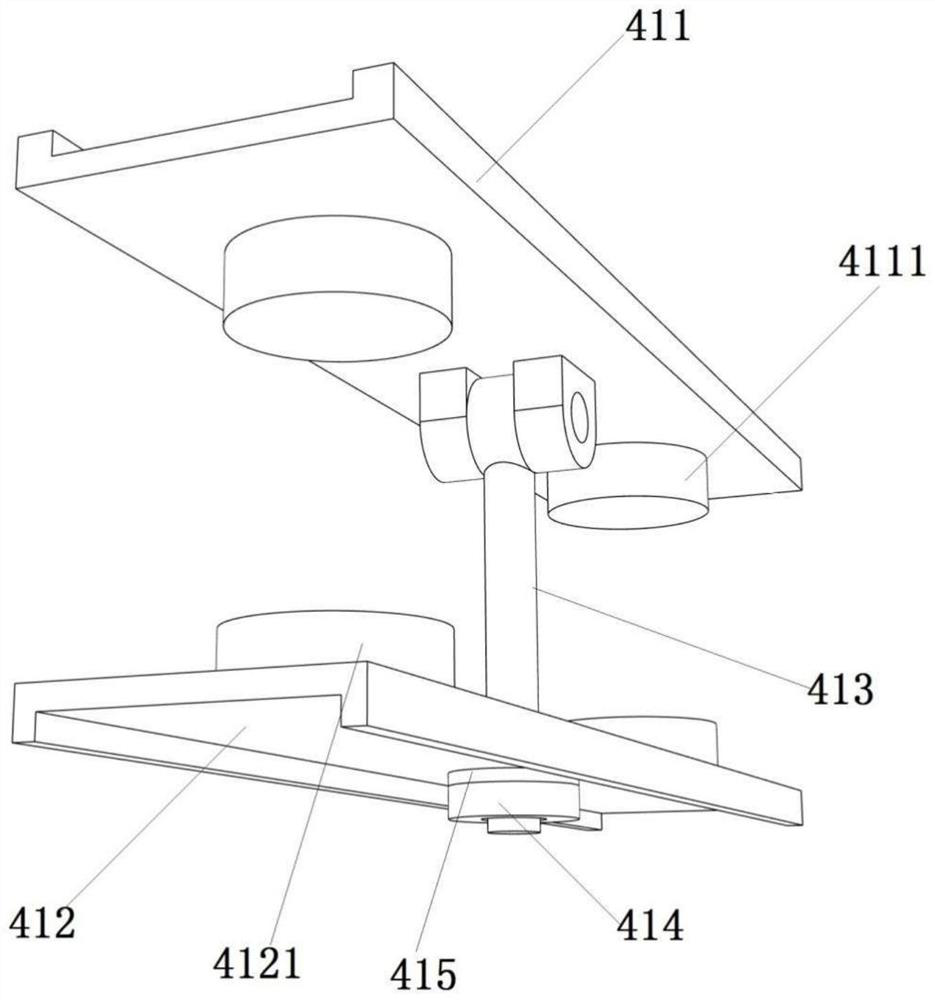

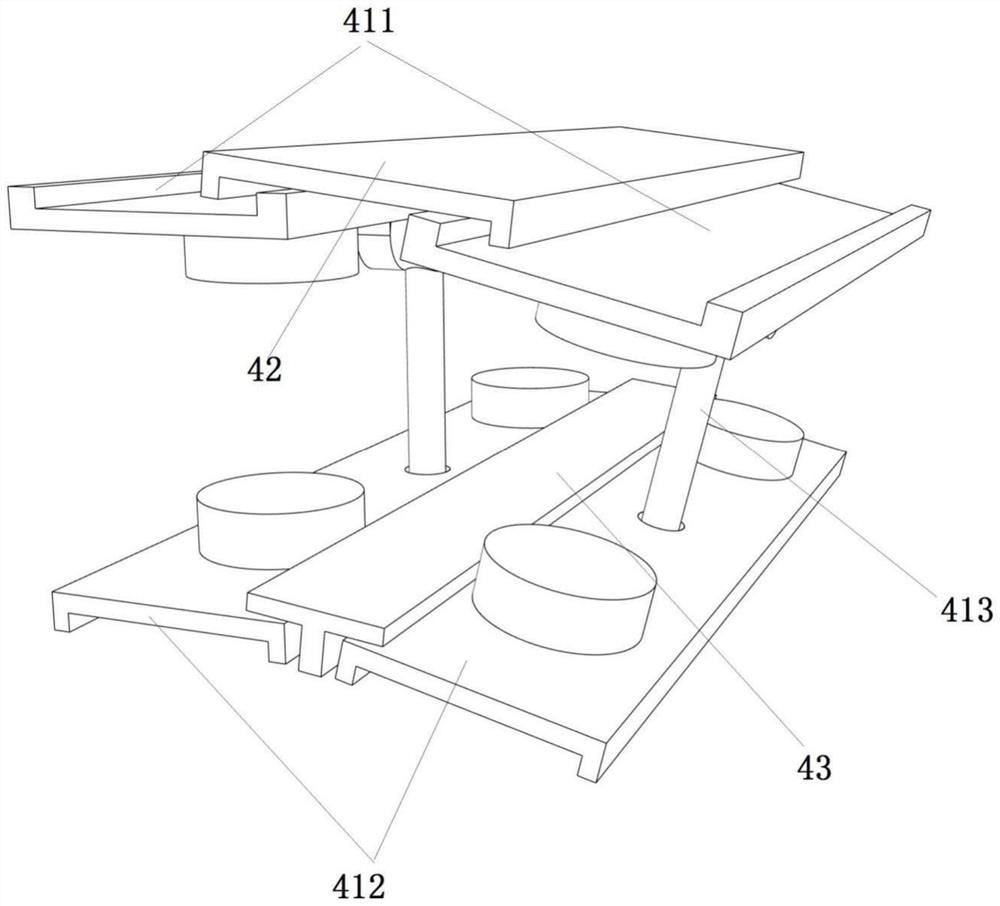

[0033] The flexible joint structure 4 of the present embodiment includes a joint bridge mechanism 41 , a bridge plate joint gusset 42 , a bridge plate joint rubber 43 , a waterproof plate protective layer 44 , a drag reduction layer 45 and a foam concrete shock-absorbing filling layer 46 . Among them, a plurality of joint bridging mechanisms 41 are provided, and the plurality of joint bridging mechanisms 41 are arranged in the circumferential direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com