Steam merging method used for two-on-one gas-steam combined cycle unit

A combined cycle unit and steam technology, which is applied in the direction of steam engine devices, mechanical equipment, engine components, etc., can solve the problems of slow load response speed, high energy consumption, and affecting the safe and stable operation of the unit, so as to reduce energy consumption and increase load The effect of response speed and shortening the time-consuming process of steam paralleling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

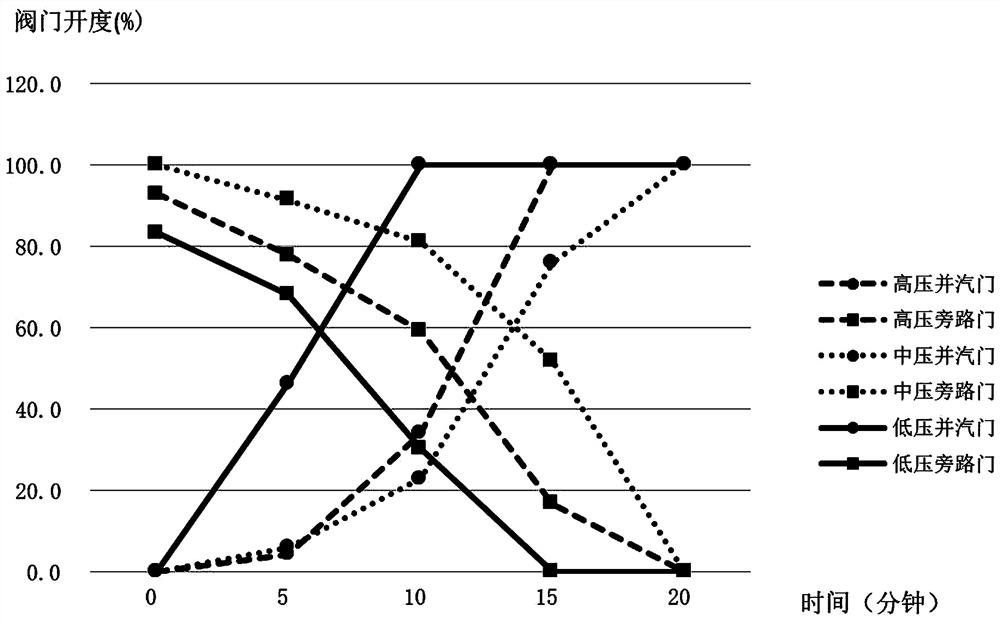

[0043] A steam paralleling method for a two-to-one gas-steam combined cycle unit, the method is realized by the following steps:

[0044] First, set the parallel steam conditions of the unit; the steam parallel conditions include:

[0045] 1) The temperature deviation of high-pressure main steam is ≤15℃, and the pressure deviation of high-pressure main steam is ≤0.1MPa;

[0046] 2) The temperature deviation of the medium-pressure main steam is ≤80°C, and the pressure deviation of the medium-pressure main steam is ≤0.1MPa;

[0047] 3) The temperature deviation of low-pressure main steam is ≤80℃, and the pressure deviation of low-pressure main steam is ≤0.05MPa;

[0048] 4) The load of the two gas turbines is 150MW;

[0049] When the unit reaches the condition of paralleling steam, start paralleling steam; the specific steps are as follows:

[0050] Step 1: Perform the following operations synchronously within 0 to 5 minutes:

[0051] 1) Adjust the valve opening of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com