Device for controlling temperature of chromatographic column and manufacturing method thereof

A chromatographic column and temperature sensor technology, which is applied in the field of chromatographic analysis, can solve problems such as the inability to solve the heat loss of gas bath heating, the inability to achieve precise control of low temperature, and the high power of the column thermostat, so as to achieve low power consumption, reduce cooling time, and reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

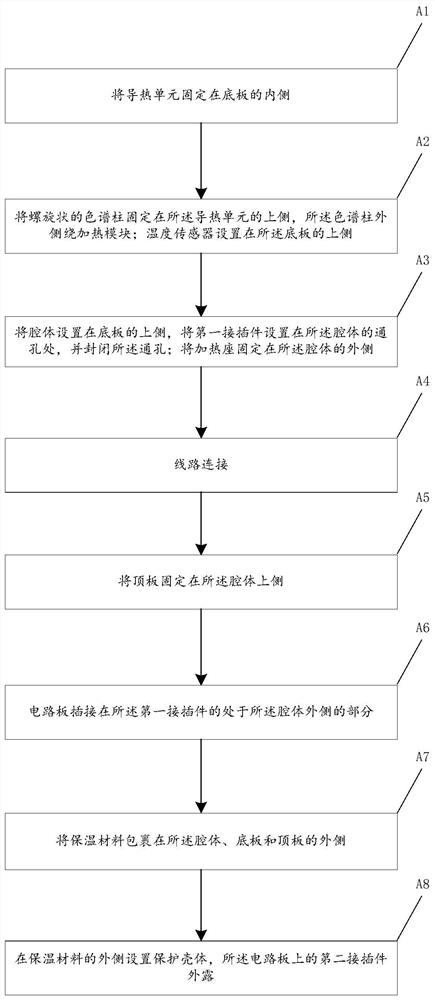

Method used

Image

Examples

Embodiment 1

[0042] The device for controlling the temperature of the chromatographic column according to the embodiment of the present invention, the device for controlling the temperature of the chromatographic column includes:

[0043] A chromatographic column, a bottom plate, a cavity and a top plate, wherein the bottom plate, the cavity and the top plate enclose a closed space, and the chromatographic column is arranged in the closed space;

[0044] a heat conduction unit, the heat conduction unit has heat dissipation teeth, and is arranged on the inner side of the bottom plate;

[0045] a refrigeration unit, such as a TEC, the refrigeration unit is arranged on the outside of the bottom plate and is in contact with the heat conduction unit;

[0046] a circuit board, the circuit board is arranged on the outside of the cavity;

[0047] A heating module, such as an insulated heating wire, wraps the chromatographic column around the heating module, and the spiral chromatographic column i...

Embodiment 2

[0081] An application example of the device for controlling a chromatographic column and its manufacturing method according to Embodiment 1 of the present invention.

[0082] In this application example, the inner wall of the rectangular bottom plate has a sixth annular groove, and a sixth O-ring is arranged inside, and there is a rectangular through hole in the area enclosed by the sixth annular groove, and the rectangular through hole and the sixth annular groove There are mounting holes between them;

[0083] The side of the heat conduction unit facing the rectangular through hole is flat, and the other side facing away from the rectangular through hole has heat dissipation teeth distributed in an array. The screws pass through the heat conduction unit and are fixed on the mounting holes, thereby fixing the heat conduction unit on the The inner side of the above-mentioned rectangular through hole, that is, the inner side of the bottom plate; multiple support columns are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com