Semiconductor process equipment and temperature control method thereof

A process equipment and semiconductor technology, applied in semiconductor/solid-state device manufacturing, metal material coating process, ion implantation plating, etc., can solve the problems of low control efficiency and low control accuracy, so as to ensure accuracy and timely adjustment , Improve the effect of temperature control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

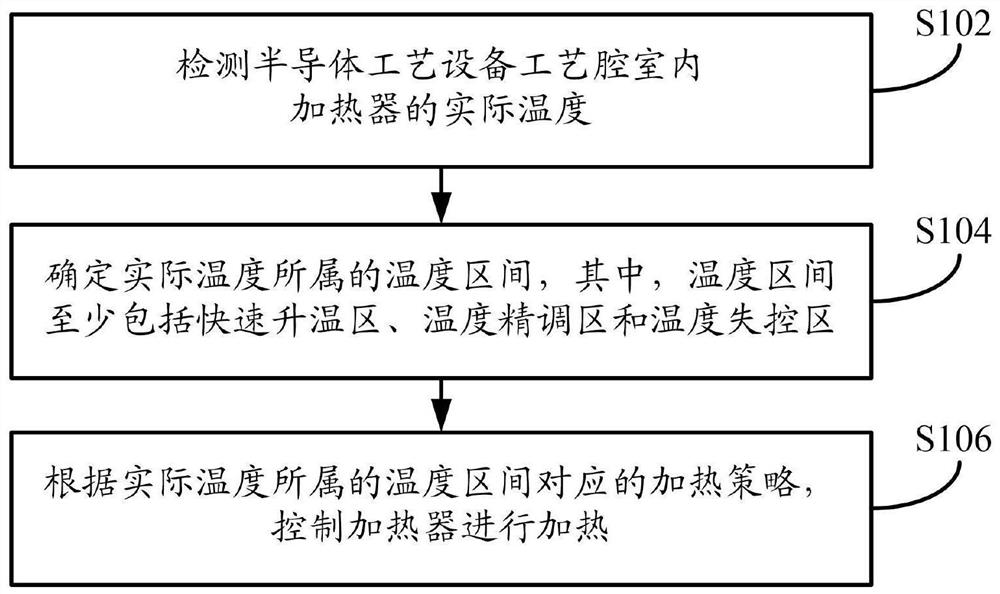

[0082] Such as figure 1 As shown, the embodiment of the present invention provides a temperature control method for semiconductor process equipment. The execution subject of the method may be the controller of the semiconductor process equipment, or the server of the semiconductor process equipment. The server may be an independent server or Can be a server cluster consisting of multiple servers. The method specifically may include the following steps:

[0083] In S102, the actual temperature of the heater in the process chamber of the semiconductor process equipment is detected.

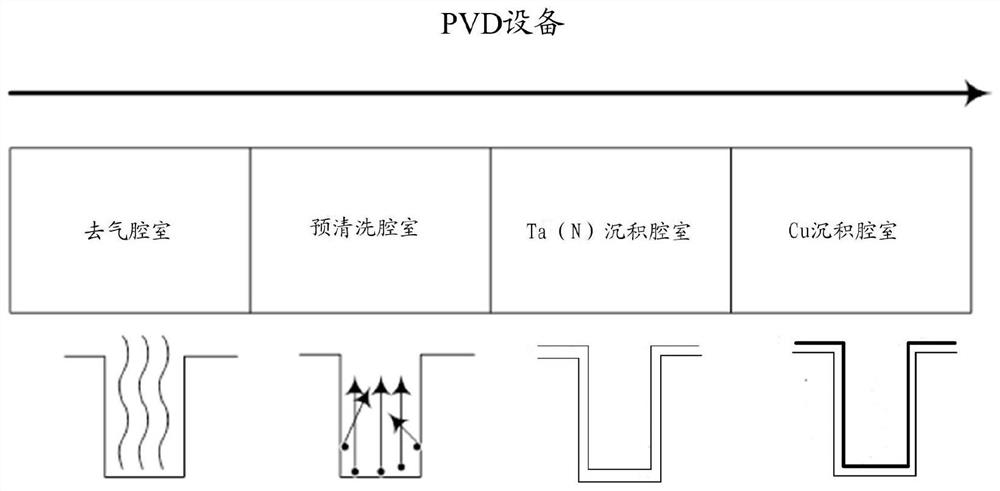

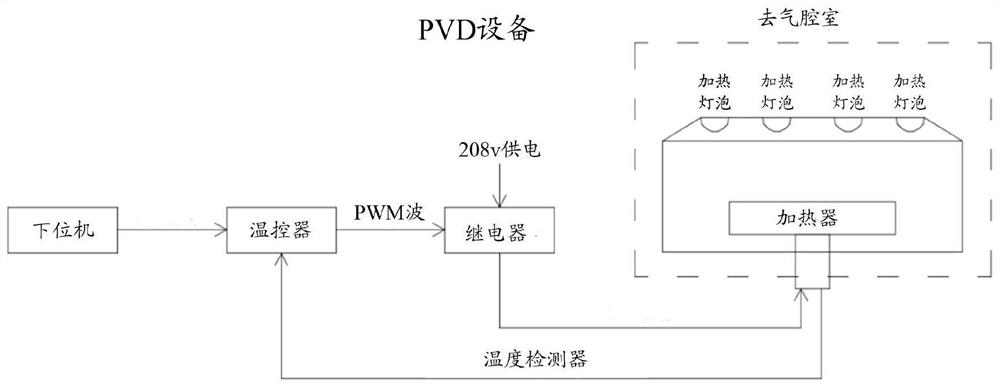

[0084] Take copper interconnection equipment in PVD equipment as an example, such as figure 2 As shown, in this PVD equipment, there can be 4 chambers, including a degassing chamber, a pre-cleaning chamber, a Ta(N) deposition chamber and a Cu deposition chamber, which can be used to perform a heating degassing process ( That is, cleaning process), pre-cleaning process, Ta(N) deposition process a...

Embodiment 2

[0100] Such as Figure 4 As shown, the embodiment of the present invention provides a temperature control method for semiconductor process equipment. The execution subject of the method may be the controller of the semiconductor process equipment, or the server of the semiconductor process equipment. The server may be an independent server or Can be a server cluster consisting of multiple servers. The method specifically may include the following steps:

[0101] In S402, the target temperature of the heater and a preset safety margin are obtained.

[0102] In S404, historical temperature rise data within a preset time is acquired.

[0103] Among them, taking PVD equipment as an example, the preset time can be nearly one month or nearly half a year, etc., and the historical temperature rise data can be the temperature rise in the process chamber when the PVD equipment is heated based on the target temperature.

[0104] For example, in the past three months, when the process se...

Embodiment 3

[0147] The above is the temperature control method for semiconductor process equipment provided by the embodiment of the present invention. Based on the same idea, the embodiment of the present invention also provides a temperature control device for semiconductor process equipment, such as Image 6 shown.

[0148] The temperature control device of the semiconductor process equipment includes: a detection module 601, a determination module 602 and a heating module 603, wherein:

[0149] A detection module 601, configured to detect the actual temperature of the heater in the process chamber of the semiconductor process equipment;

[0150] A determination module 602, configured to determine the temperature range to which the actual temperature belongs, wherein the temperature range includes at least a rapid temperature rise zone, a temperature fine adjustment zone, and a temperature out-of-control zone;

[0151] The heating module 603 is configured to control the heater to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com