Electric energy meter mounting base and electric meter box

An electric energy meter installation and electric energy meter technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of lack of insulation packaging measures, open current loop, high risk factor of live installation and disassembly, and achieve the realization of bare wire head insulation packaging, The effect of reducing screw tightening steps and avoiding the risk of human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

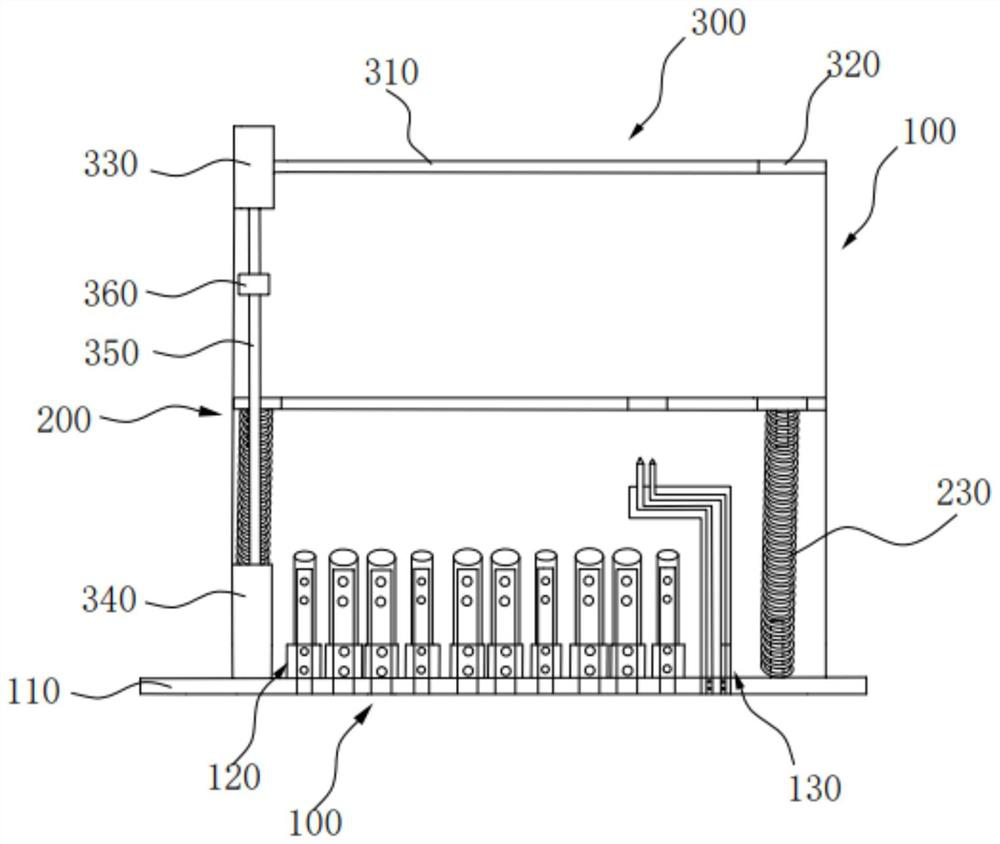

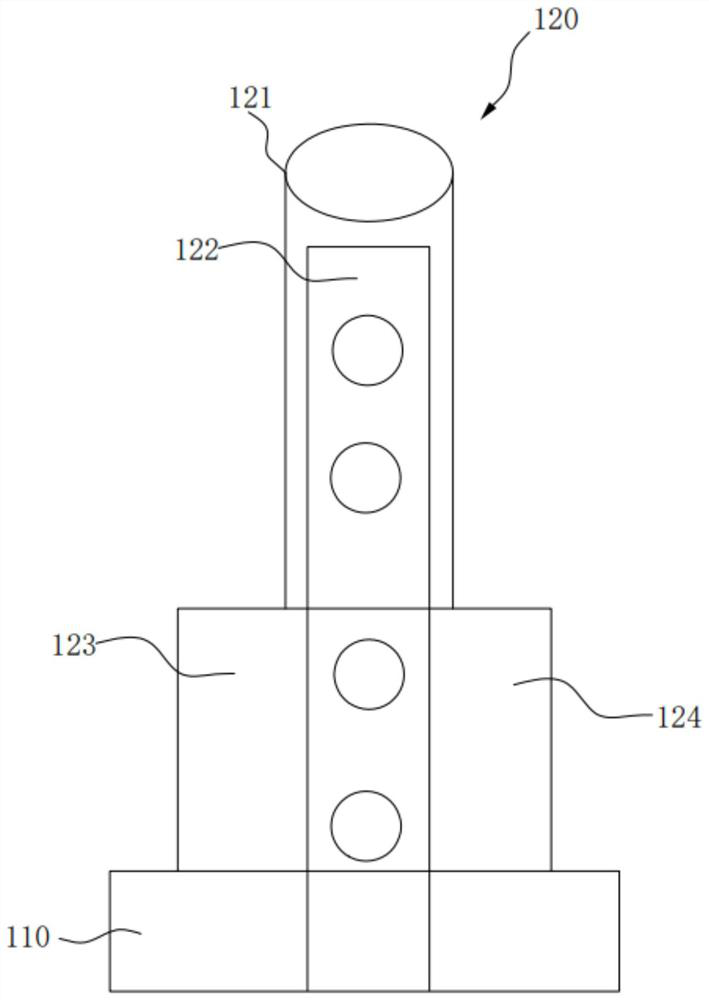

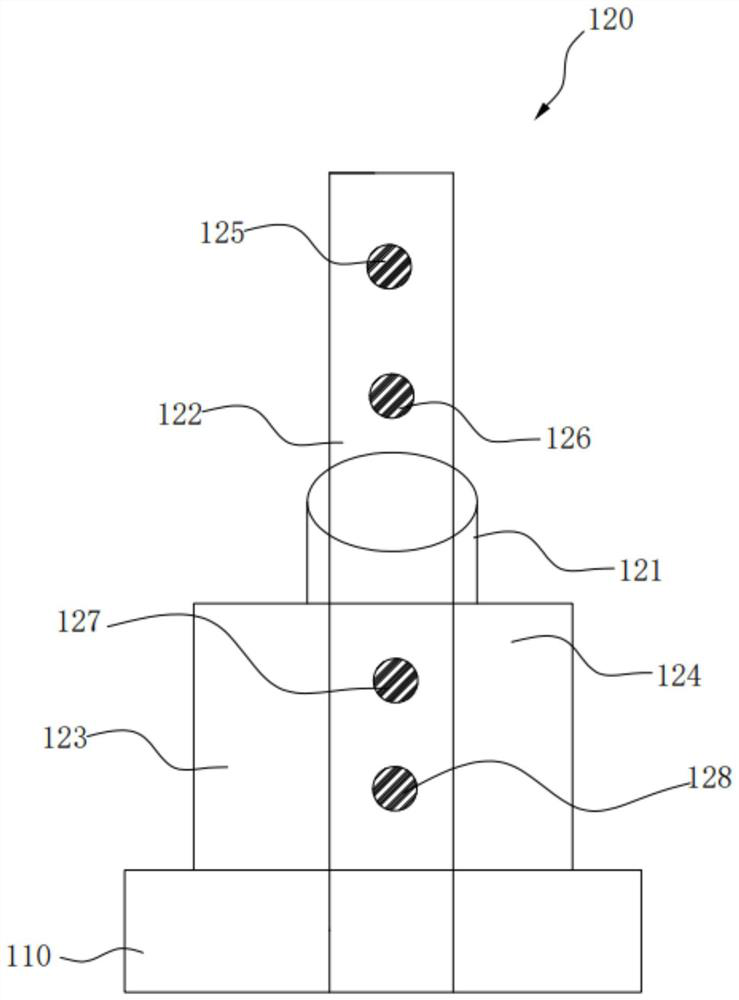

[0035] figure 1 It shows the structure diagram of the electric energy meter installation base and the electric meter box provided by the first embodiment of the present invention, figure 2 A schematic diagram of an unconnected secondary wiring fixing device provided by Embodiment 1 of the present invention is shown, image 3 A schematic diagram of the secondary wiring fixing device after wiring provided by Embodiment 1 of the present invention is shown.

[0036] refer to Figure 1-Figure 3 , The electric energy meter installation base 100 provided in this embodiment includes a bottom plate 110, a plurality of secondary wiring fixing devices 120, a communication wiring device 130, an electric energy meter accommodating device 200 and two supporting plates. A plurality of secondary wiring fixing devices 120 , a communication wiring device 130 and two support plates are vertically fixed on the base plate 110 , and the electric energy meter accommodating device 200 is elastical...

Embodiment 2

[0054] The second embodiment differs from the first embodiment only in that the communication wiring device 130 is different. Figure 7 It shows the schematic diagram of the communication wiring device provided by the second embodiment of the present invention, refer to Figure 7 , The communication wiring device 130 includes an insulating pointer sheath 131 , a pointer 132 , a communication terminal 133 and a pointer spring 134 . The pointer spring 134 is set outside the pointer 132, and the insulating pointer sheath 131 is sheathed outside the pointer spring 134 and the pointer 132. superior. The communication connection terminal of the electric energy meter is located in the communication connection port of the electric energy meter casing. The diameter of the communication connection port of the electric energy meter casing is larger than the diameter of the pointer 132 and smaller than the diameter of the insulating pointer sheath 131. When the pointer 132 is facing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com