Multifunctional transformer coil manufacturing machine

A transformer coil and multi-functional technology, which is applied in the field of coil manufacturing, can solve the problems of affecting the service life of the power mechanism, poor operation of the power mechanism, and timely cleaning of the box and the inside of the box, so as to improve efficiency, The effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

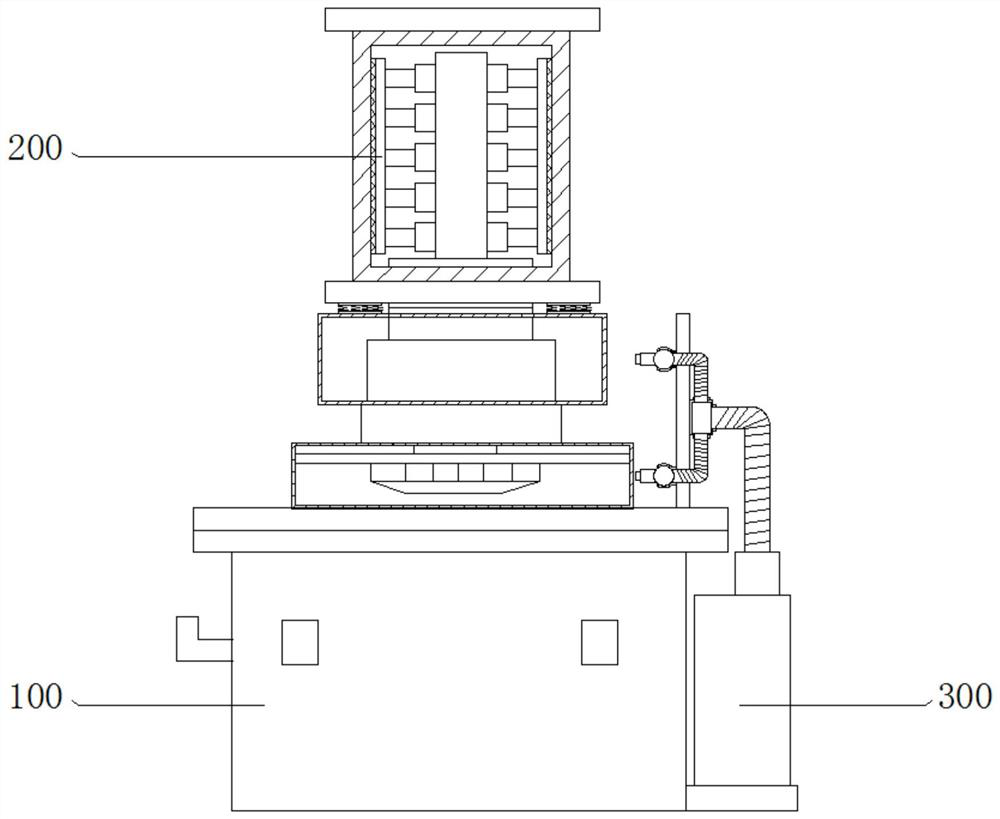

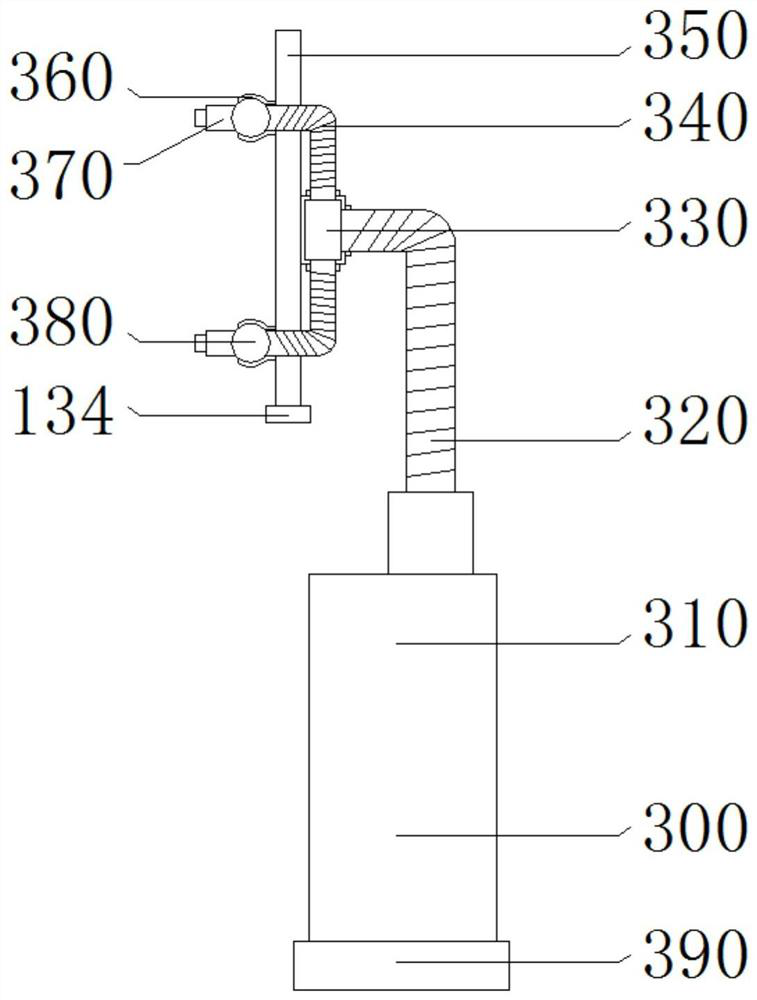

[0039] see Figure 1-6 , the present invention provides a technical solution: a multifunctional transformer coil manufacturing machine includes a base 100, an adjustment assembly 200 and a cleaning assembly 300, and the cleaning assembly 300 includes a fan 310, a connecting hose 320, a right-angle tee 330, a branch hose 340, support plate 350, ball sleeve 360, telescopic tube 370, hollow ball 380 and base 390; the top of fan 310 is provided with connecting hose 320, and one end of connecting hose 320 is provided with right-angle tee 330, right-angle tee 330 Branch hoses 340 are provided at the upper and lower ends of the branch hose 340, a hollow ball 380 is provided at one end of the branch hose 340, and a telescopic tube 370 is provided at one end of the hollow ball 380. One side of the right-angle tee 330 is fixedly connected with a support plate 350, one side of the support plate 350 is fixedly connected with a ball sleeve 360, and the hollow ball 380 is movably connected ...

Embodiment 2

[0042] see Figure 1-6 , the present invention provides a technical solution: a multi-functional transformer coil manufacturing machine includes a base 100, an adjustment assembly 200 and a cleaning assembly 300, the base 100 is used to support and fix the adjustment assembly 200, and it is convenient for the adjustment assembly 200 to carry out coils of different specifications. Roll processing.

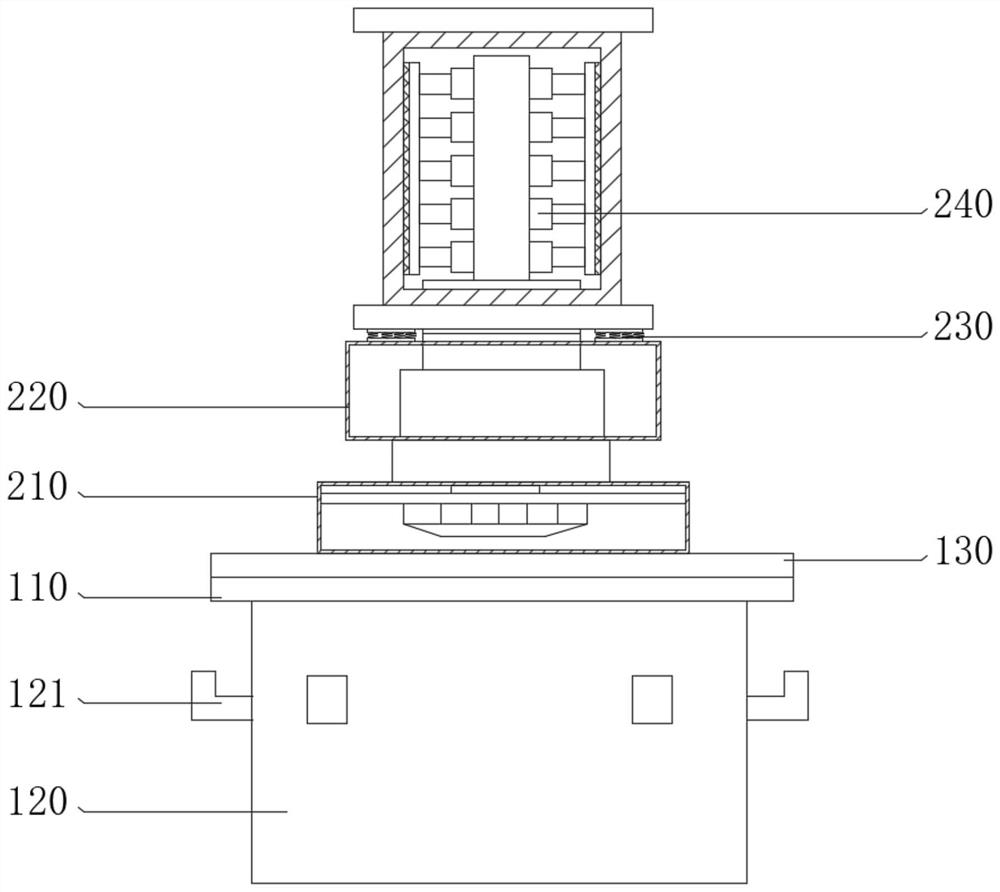

[0043] see figure 1 , image 3 with Figure 4 The base 100 includes a block body 110 and a platform body 120, the block body 110 is arranged on the top of the platform body 120, the block body 110 is arranged correspondingly to the top of the platform body 120, and a base 390 is fixedly connected to one side of the bottom end of the platform body 120, said The fan 310 is arranged on the top of the base 390, the top of the block 110 is provided with a slider 130, the number of sliders 130 is set to several, and several sliders 130 are arranged at intervals on the top of the block ...

Embodiment 3

[0046] see Figure 1-6 , the present invention provides a technical solution: a multi-functional transformer coil manufacturing machine includes a base 100, an adjustment assembly 200 and a cleaning assembly 300, the base 100 is used to support and fix the adjustment assembly 200, and it is convenient for the adjustment assembly 200 to carry out coils of different specifications. Roll processing.

[0047] see figure 1 , image 3 with Figure 4 , the base 100 includes a block body 110 and a table body 120, the block body 110 is arranged on the top of the table body 120, the block body 110 is arranged correspondingly to the top of the table body 120, and the top of the block body 110 is provided with a slider 130, and the slider 130 is set to several A plurality of sliding parts 130 are arranged at intervals on the top of the block body 110. The sliding part 130 includes a sliding groove 131, a sliding bar 132 and a sliding block 133. The bottom of the sliding groove 131 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com