Method and device for producing reinforced concrete component, and concrete component

A technology of reinforced concrete and concrete, which is applied in the field of manufacturing reinforced concrete components and manufacturing reinforced concrete components, which can solve the problems of corrosion, low flexibility of steel bars, insufficient bonding, etc., and achieve excellent performance and durable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

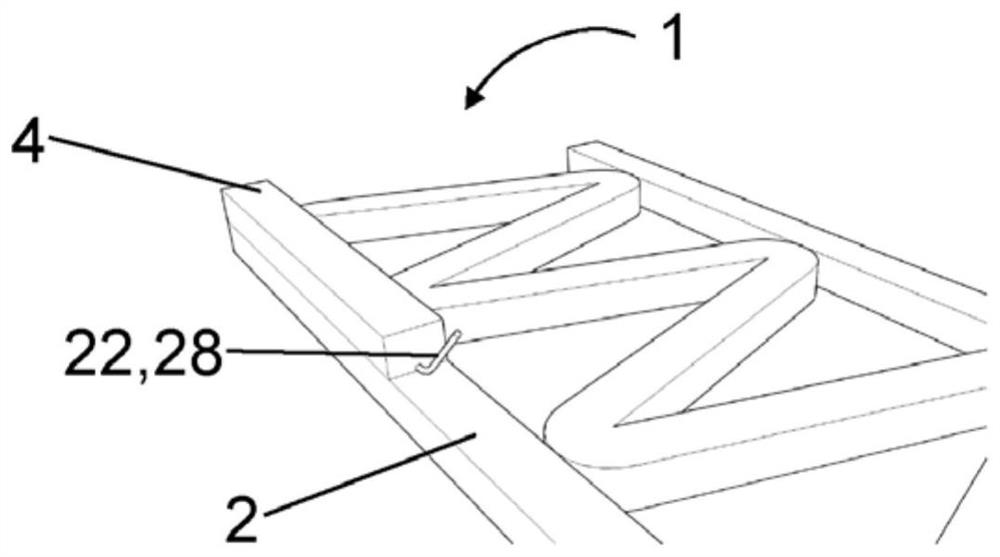

[0095] figure 1 A schematic diagram showing an embodiment of the inventive concrete element 1 with embedded longitudinal reinforcements 22 embodied as reinforcing fiber strands 28 . The reinforcing fiber strands 28 are embedded in the concrete strands 4 . The concrete strands 4 are placed on the concrete layer 2 formed by the previously manufactured concrete strands 4 , so that the layer-by-layer additive manufacturing of the concrete element 1 is achieved.

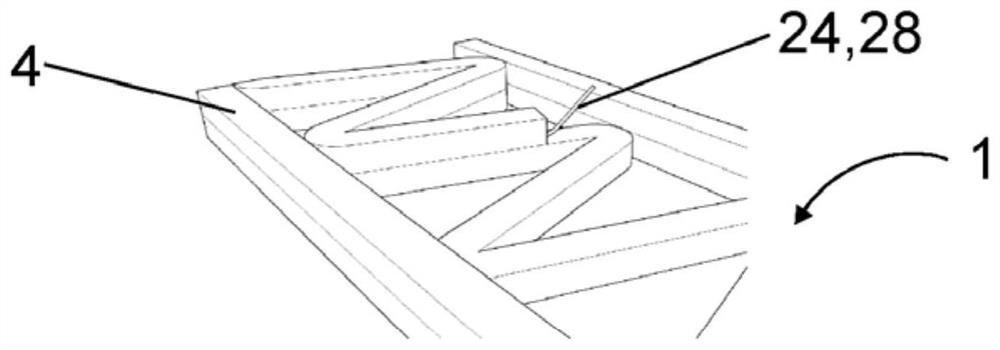

[0096] figure 2 A schematic diagram showing an embodiment of the inventive concrete element 1 embedded with a transverse reinforcement 24 formed by reinforcing fiber strands 28 . The transverse reinforcement 24 provides strength to the beam embedded in the concrete member 1 in a zigzag shape. The reinforcing fiber strands 28 are likewise embedded in the concrete strands 4 here.

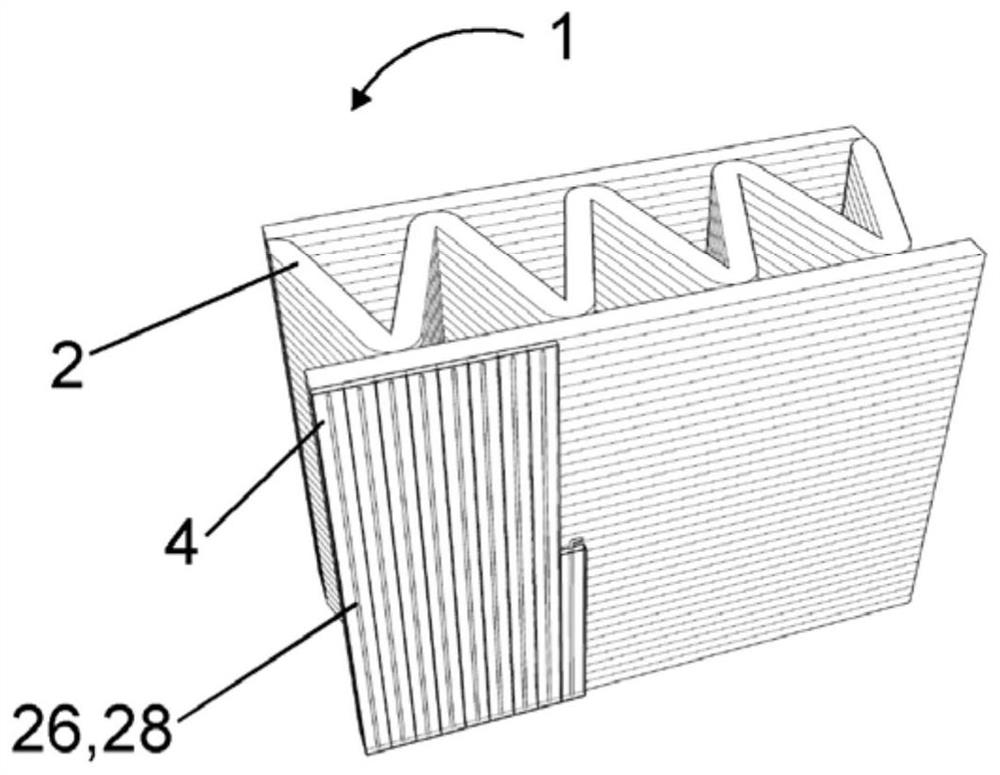

[0097] image 3 A schematic diagram showing an embodiment of the inventive concrete element 1 embedded with vertical reinforcements 26 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com