Full-circle inverted buckle demolding sliding block structure

A slider and undercut technology, which is applied in the field of full-circle undercut and stripping slider structures, can solve the problems of complex structural design, small space, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

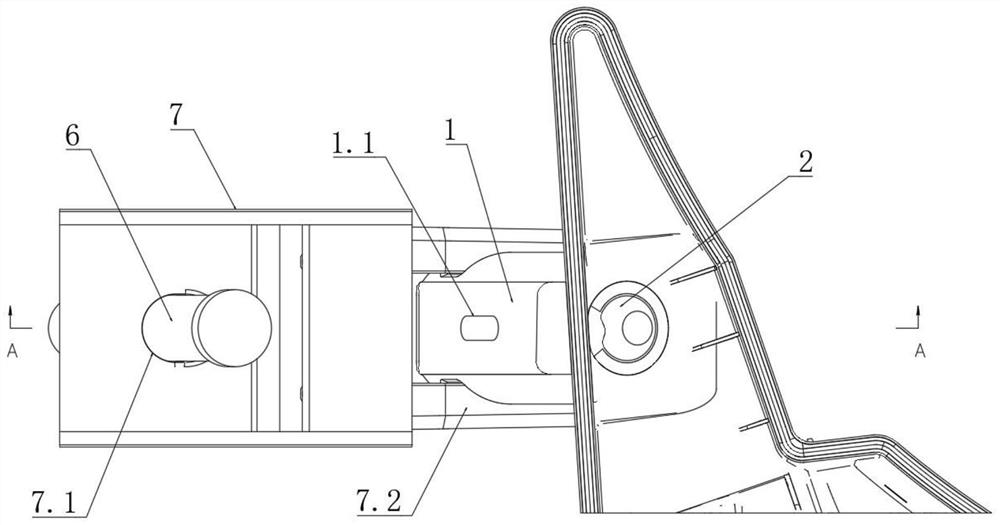

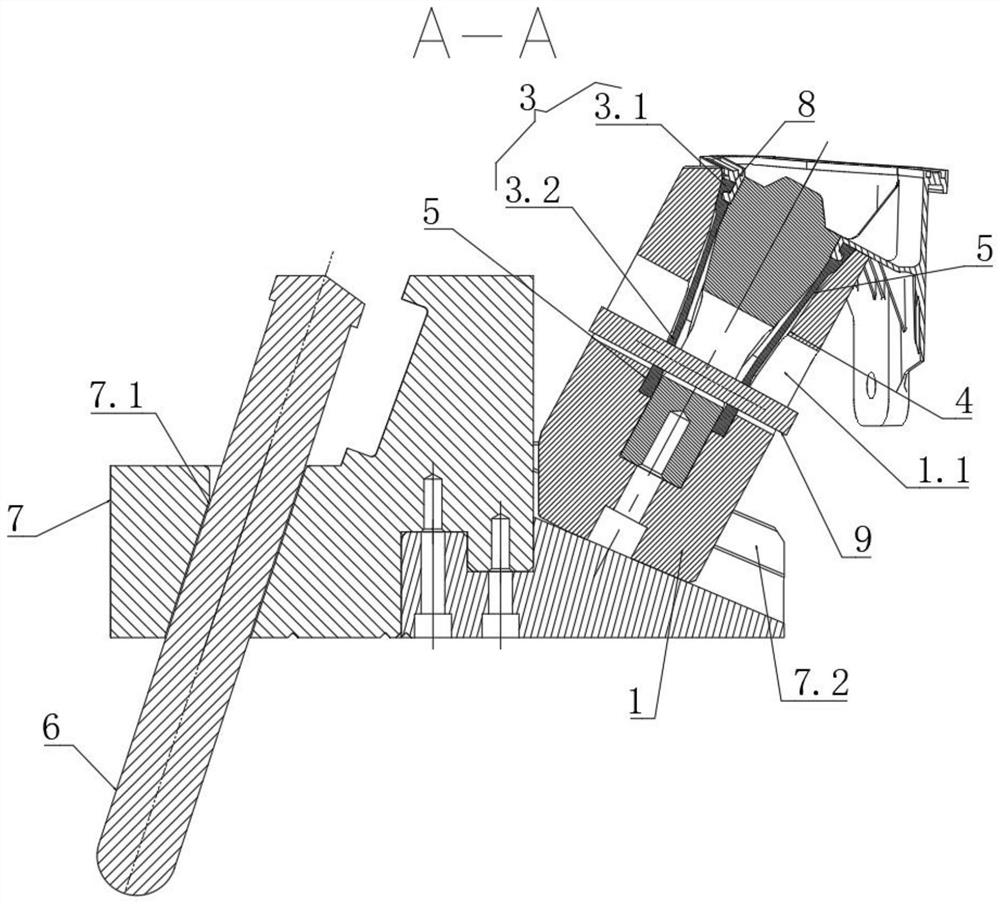

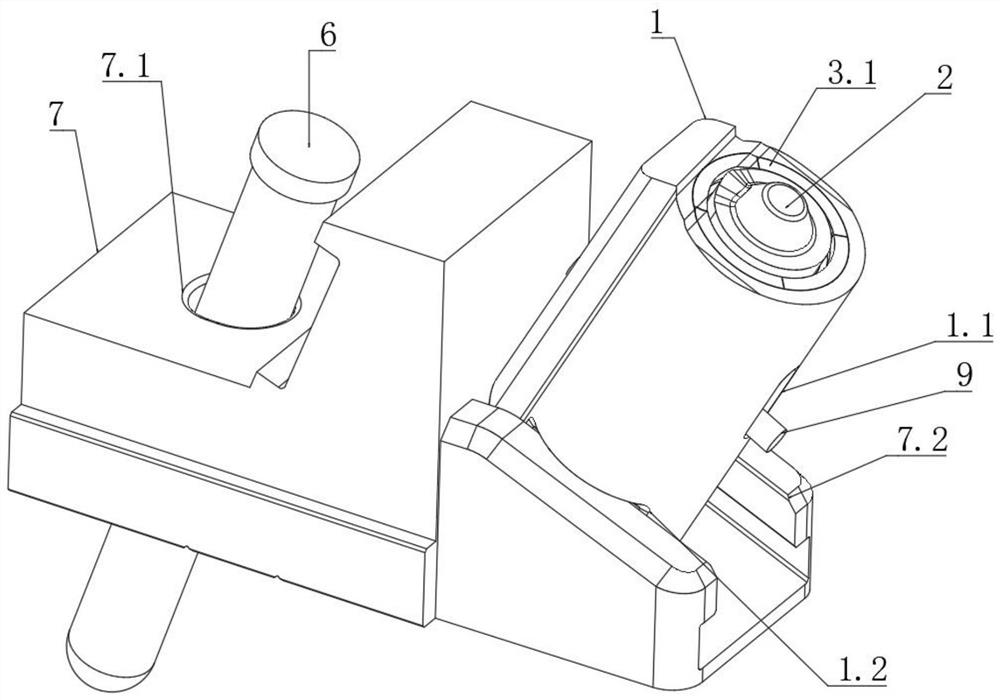

Method used

Image

Examples

no. 1 example

[0057] The above content is the first embodiment of the present invention, in the first embodiment, the position of the pin body 9 is fixed;

[0058] see Figure 5 , Figure 5 This is the second embodiment of the present invention. In the second embodiment, the position of the pin body 9 is floating. In the second embodiment, a first connecting hole 10 and a second connecting hole 11 are arranged horizontally above the slider seat 7, a contour screw 10.1 is connected in the first connecting hole 10, and a positioning piece is connected to the right end of the contour screw 10.1 10.2, the positioning part 10.2 is obliquely provided with a matching groove 10.21 for matching with the pin body 9, and an elastic part is provided between the positioning part 10.2 and the second connecting hole 11;

[0059] In the second embodiment: during injection molding, the elastic member drives the positioning member 10.2 against the left end surface of the sliding seat, the pin body 9 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com