Box culvert construction assembly, application thereof and box culvert construction method

A construction method and box culvert technology, applied in the field of construction, can solve problems such as broken wooden formwork, inconvenient transportation and installation, deformation of steel formwork, etc., to achieve the effects of ensuring construction quality, improving construction efficiency, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

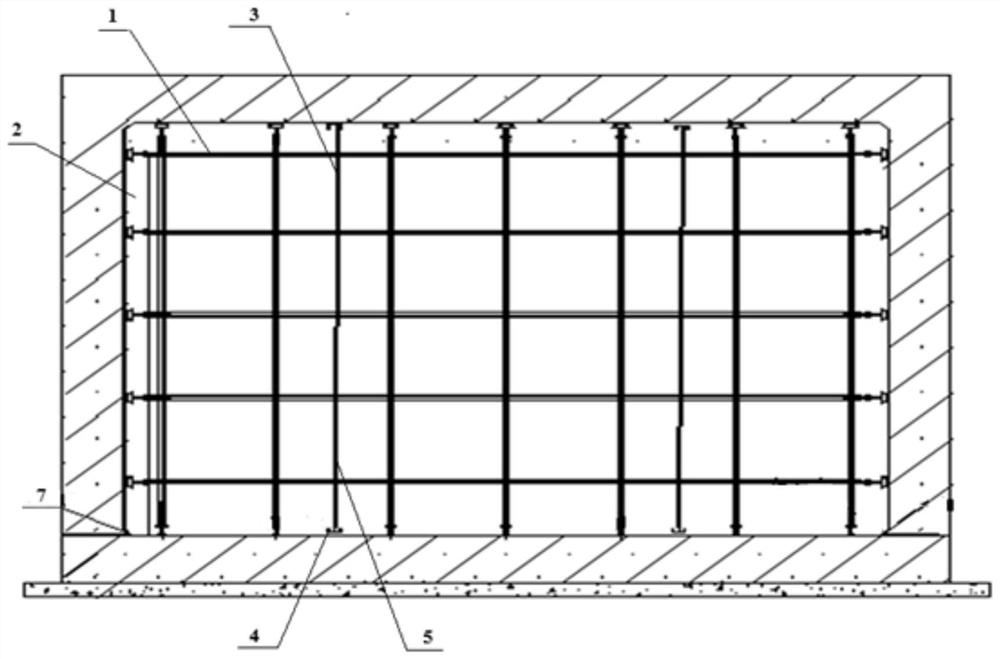

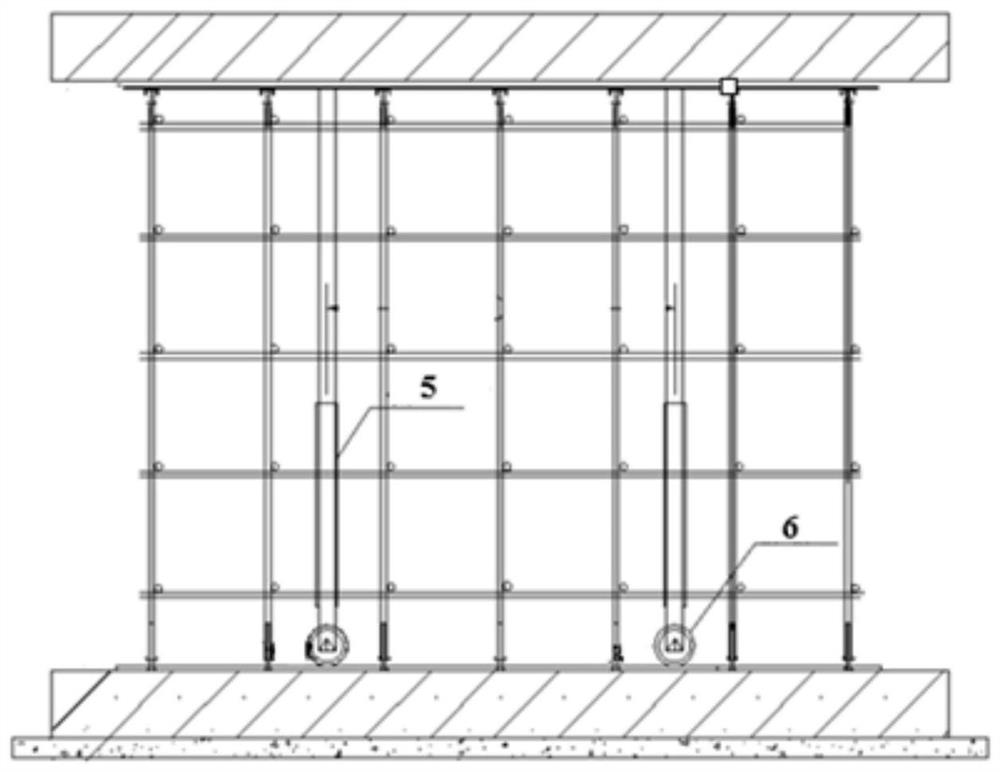

[0115] This embodiment provides a box culvert construction assembly, which includes a full hall support 1, a support beam 3, a horizontal scissor brace, a steel formwork 2, a pulley 6, a slide rail 4, a mechanical hydraulic device 5, a foam board 7, a hoist or a hand pull Hoist, crane.

[0116] A plurality of steel formworks 2 are used to assemble a box culvert inner formwork frame matching the preset box culvert shape. The full hall support 1 is erected in the box culvert inner formwork frame and connected with the inner wall of each steel formwork 2; the support beam 3 is longitudinally connected to the The top of the full hall support 1 is connected with the steel formwork 2 at the same time, the slide rail 4 is laid on the bottom of the full hall support 1 along the culvert length direction of the preset box culvert, and the pulley 6 is connected with the supporting beam 3 and used for sliding along the slide rail 4.

[0117] Among them, all the two connected steel formwor...

Embodiment 2

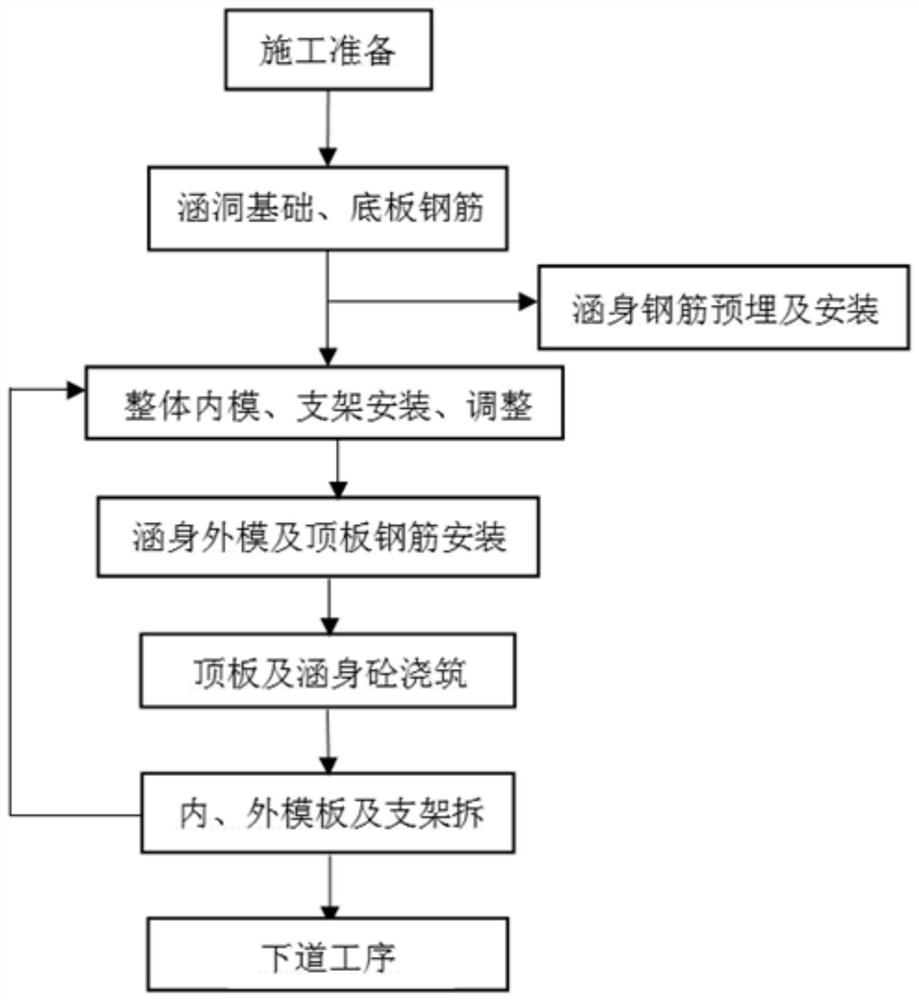

[0123] This embodiment provides a method for constructing a box culvert, and the components provided in Embodiment 1 are used in the construction process. refer to image 3 The process of box culvert construction method includes construction preparation (culvert foundation, bottom plate reinforcement, culvert body reinforcement pre-embedded and installation), overall inner formwork and support installation and adjustment, culvert body outer formwork and roof reinforcement installation, roof and culvert body concrete Pouring, removal of internal and external formwork and brackets, and the next process.

[0124] Among them, construction preparation includes:

[0125] Before construction, according to the cross-sectional size of the box culvert, custom-made chamfering, oblique plugs and other special-shaped formwork, the rest of the position can be 900 × 1500 ordinary flat mold, the inner mold is processed and customized according to the cross-sectional size of the box culvert, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap