A kind of detection method of anti-scale explosion performance of hot-rolled and pickled enamel steel plate

A technology of hot-rolled pickling and detection method, which is applied in the detection of anti-scaling performance of hot-rolled pickling enamel steel sheet, and in the field of detection of performance of hot-rolled pickling enamel steel sheet, which can solve the problem of anti-scaling performance of hot-rolled pickling enamel steel sheet Unable to accurately detect and other problems, to achieve the effect of shortening the observation period, overcoming probability problems, and reliable safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

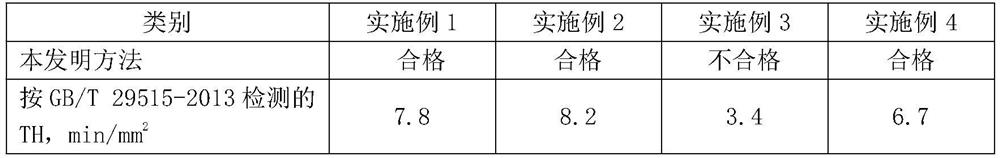

Embodiment 1

[0034] Example 1, the brand name of the hot-rolled acid-washed steel sheet for enamel is Q330RT.

[0035] A method for detecting the anti-scaling performance of a hot-rolled and pickled enamel steel sheet, comprising the following steps:

[0036] 1) Prepare a sample, cut a rectangular sample from the hot-rolled acid-washed enamel steel plate for enamel to be tested, the sample length is 100mm, the width is 60mm, and the thickness is 3.5mm; the surface of the sample is degreased and cleaned, and the control test is carried out. The surface cleanliness of the sample is 95%;

[0037]2) The sample is coated with enamel glaze by wet coating method, and the dry powder of enamel glaze is prepared into colloidal enamel glaze with deionized water. The ratio is 200:70; the surface of the sample is coated and smeared with colloidal enamel glaze, and the thickness of each smeared colloidal enamel glaze is 0.05-0.10mm, and the surface of one side of the sample and the enamel glaze of four...

Embodiment 2

[0040] Example 2, the brand name of the hot-rolled acid-washed steel sheet for enamel is Q330RT.

[0041] A method for detecting the anti-scaling performance of a hot-rolled and pickled enamel steel sheet, comprising the following steps:

[0042] 1) Prepare a sample, cut a rectangular sample from the hot-rolled acid-washed enamel steel plate for enamel to be tested, the sample length is 100mm, the width is 70mm, and the thickness is 1.5mm; the surface of the sample is degreased and cleaned, and the control test is carried out. The surface cleanliness of the sample is 90%;

[0043] 2) The sample is coated with enamel glaze by wet coating method, and the dry powder of enamel glaze is prepared into colloidal enamel glaze with deionized water. The ratio is 200:75; the surface of the sample is coated and smeared with colloidal enamel glaze, and the thickness of each smeared colloidal enamel glaze is 0.05-0.10mm, and the surface of one side of the sample and the enamel glaze of fou...

Embodiment 3

[0046] Example 3, the brand name of the hot-rolled acid-washed steel sheet for enamel is Q210RT.

[0047] A method for detecting the anti-scaling performance of a hot-rolled and pickled enamel steel sheet, comprising the following steps:

[0048] 1) Prepare a sample, cut a rectangular sample from the hot-rolled acid-washed enamel steel plate for enamel to be tested, the sample length is 150mm, the width is 70mm, and the thickness is 2.7mm; the surface of the sample is degreased and cleaned, and the control test is carried out. The surface cleanliness of the sample is 95%;

[0049] 2) The sample is coated with enamel glaze by wet coating method, and the dry powder of enamel glaze is prepared into colloidal enamel glaze with deionized water. The ratio is 200:80; apply colloidal enamel glaze to the surface of the sample, and the thickness of each application of colloidal enamel glaze is 0.05-0.10mm, and control the surface of one side of the sample and the enamel glaze of four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com