Method for detecting fish scaling resistance of hot-rolled pickled enameled steel plate

The technology of hot-rolled pickling and detection method is applied in the detection of the anti-scaling performance of hot-rolled and pickled enamel steel sheets, and the field of testing the properties of hot-rolled and pickled enamel steel sheets, and can solve the problem of the anti-scaling performance of hot-rolled and pickled enamel steel sheets. Inability to accurately detect and other problems, to achieve the effect of shortening the observation period, reliable safety factor, and overcoming the probability problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

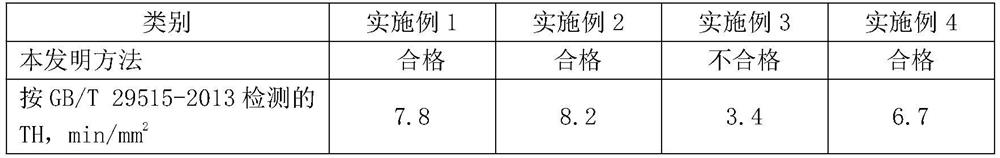

Embodiment 1

[0034] Example 1, the grade of the hot-rolled pickled steel plate for enamel is Q330RT.

[0035] A method for detecting scale explosion resistance of hot-rolled pickled enamel steel plate, comprising the following steps:

[0036] 1) Prepare the sample, intercept a rectangular sample at the hot-rolled pickling enamel steel plate to be tested, the sample length is 100mm, the width is 60mm, and the thickness is 3.5mm; the surface of the sample is degreased, cleaned, and the control test Sample surface cleanliness 95%;

[0037]2) Apply the enamel glaze to the sample by the wet coating method, adjust the dry powder of the enamel glaze with deionized water to make a colloidal enamel glaze, and the mass ratio of the dry enamel glaze powder and deionized water in the colloidal enamel glaze The ratio is 200:70; the surface of the sample is coated with colloidal enamel glaze, and the thickness of the colloidal enamel glaze is 0.05-0.10mm each time, and the surface of one side of the sa...

Embodiment 2

[0040] Example 2, the grade of the hot-rolled pickled steel plate for enamel is Q330RT.

[0041] A method for detecting scale explosion resistance of hot-rolled pickled enamel steel plate, comprising the following steps:

[0042] 1) Prepare the sample, cut a rectangular sample at the hot-rolled pickling enamel steel plate to be tested, the sample length is 100mm, the width is 70mm, and the thickness is 1.5mm; the surface of the sample is degreased, cleaned, and the control test Sample surface cleanliness 90%;

[0043] 2) Apply the enamel glaze to the sample by the wet coating method, adjust the dry powder of the enamel glaze with deionized water to make a colloidal enamel glaze, and the mass ratio of the dry enamel glaze powder and deionized water in the colloidal enamel glaze The ratio is 200:75; the surface of the sample is coated with colloidal enamel glaze, and the thickness of the colloidal enamel glaze is 0.05-0.10mm each time, and the surface of one side of the sample ...

Embodiment 3

[0046] Example 3, the grade of the hot-rolled pickled steel plate for enamel is Q210RT.

[0047] A method for detecting scale explosion resistance of hot-rolled pickled enamel steel plate, comprising the following steps:

[0048] 1) Prepare the sample, cut a rectangular sample from the hot-rolled acid-washed enamel steel plate to be tested, the sample length is 150mm, the width is 70mm, and the thickness is 2.7mm; the surface of the sample is degreased, cleaned, and the control test Sample surface cleanliness 95%;

[0049] 2) Apply the enamel glaze to the sample by the wet coating method, adjust the dry powder of the enamel glaze with deionized water to make a colloidal enamel glaze, and the mass ratio of the dry enamel glaze powder and deionized water in the colloidal enamel glaze The ratio is 200:80; the surface of the sample is coated with colloidal enamel glaze, and the thickness of the colloidal enamel glaze is 0.05-0.10mm each time, and the surface of one side of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com