Chemical raw material storage device

A technology for storage devices and chemical raw materials, which is applied in the field of storage tanks, can solve problems such as reducing the volatilization intensity of hydrochloric acid, and achieve the effects of reducing easy splashing, reducing shaking, and stabilizing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

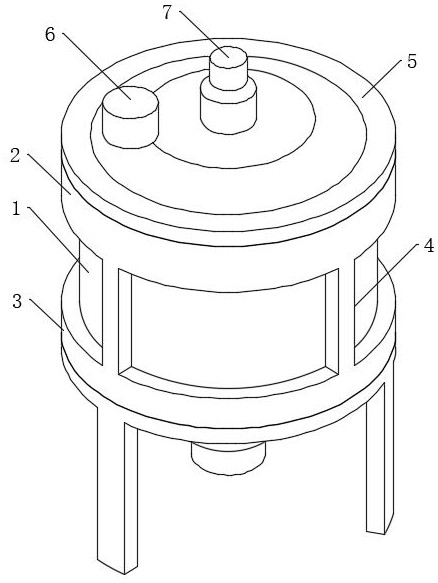

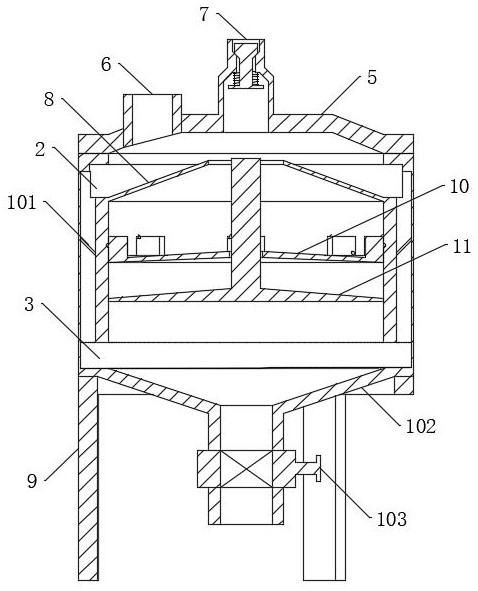

[0028] Such as Figure 1-2 As shown, the present invention is a chemical raw material storage device including a cylinder 1 having an opening, and both ends of the circumferential side of the cylinder 1 respectively provided annular 1 2 and the annular two 3, and the inner side of the ring 2 2 There is a loop tank in which the inner communication with the cylinder 1 is opened, and the inner side of the ring 2 3 is connected to the annular groove two inner communication with the cylinder 1, and the annular 1 2 is connected between the annular two 3. ;

[0029] A cover body 5 is mounted on the opening of the cylinder 1, and the cover 6 and the pressure relief tube 7 communicating with the cylinder 1 are attached to the cover 5;

[0030] The inner opening of the opening of the cylinder 1 is provided with an upward tapered housing 8.

[0031] The hydrochloric acid is poured into the cylindrical body 1 inside the cylinder 1 by the liquid hydrochloric acid, and the tapered housing 8 prov...

Embodiment 2

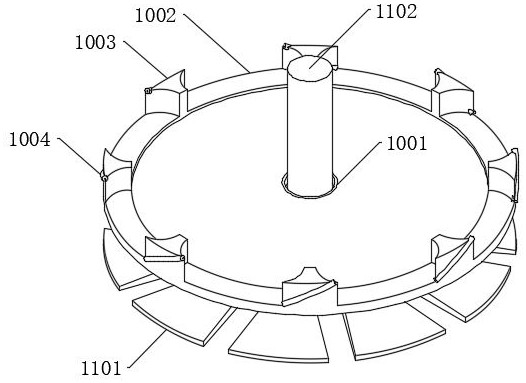

[0037] Such as Figure 2-4 As shown, the present invention is a chemical raw material storage device including a cylinder 1 having an opening, and both ends of the circumferential side of the cylinder 1 respectively provided annular 1 2 and the annular two 3, and the inner side of the ring 2 2 There is a loop tank in which the inner communication with the cylinder 1 is opened, and the inner side of the ring 2 3 is connected to the annular groove two inner communication with the cylinder 1, and the annular 1 2 is connected between the annular two 3. The opening body 5 is mounted on the opening of the cylinder 1, and the cover 6 and the pressure relief tube 7 communicating with the cylinder 1; the inner side of the opening of the cylinder 1 is provided with an upward cone. Scribe 8.

[0038] The bottom end of the cylinder 1 is provided with a bottom case 102, the bottom case 102 is a cone structure, and the middle portion of the bottom case 102 extends the tube body, and the tube bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com