Anti-blocking device for buffer stock bin

A cushioning silo and anti-blocking technology, applied in the field of buffering silos, can solve the problems of increasing workload of post workers, affecting smooth feeding, unfavorable application and operation, etc., and achieves the effect of improving the effect of anti-adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

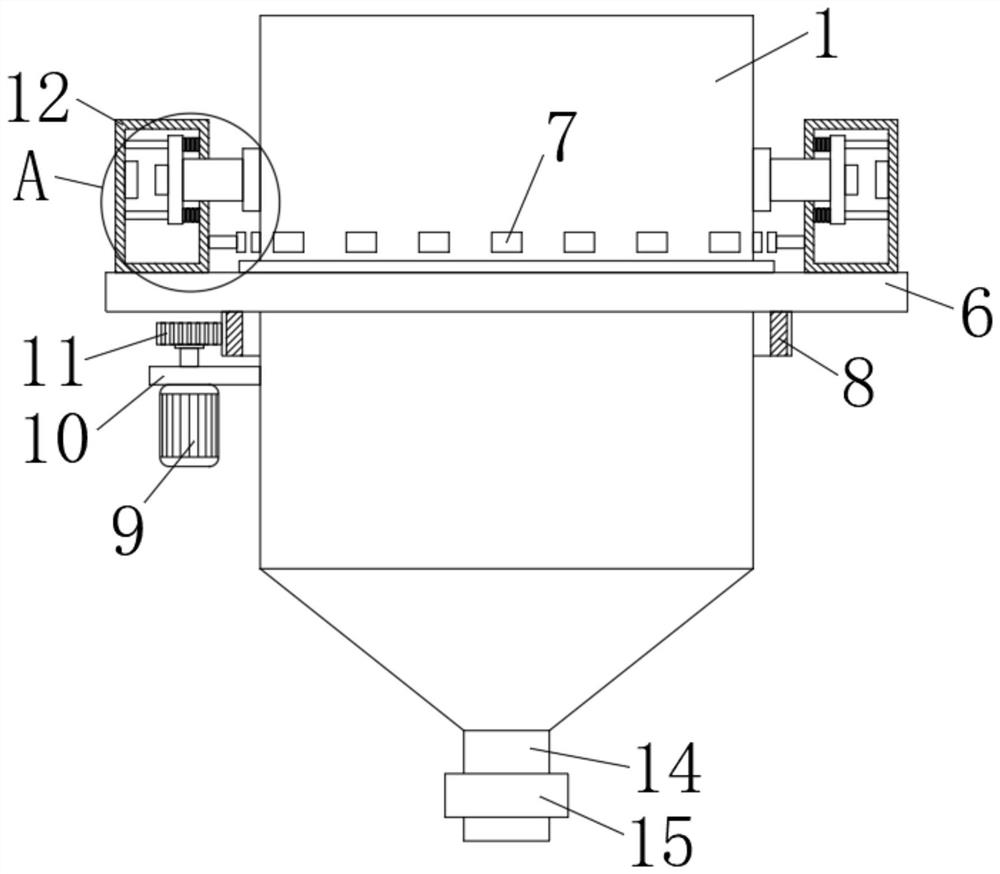

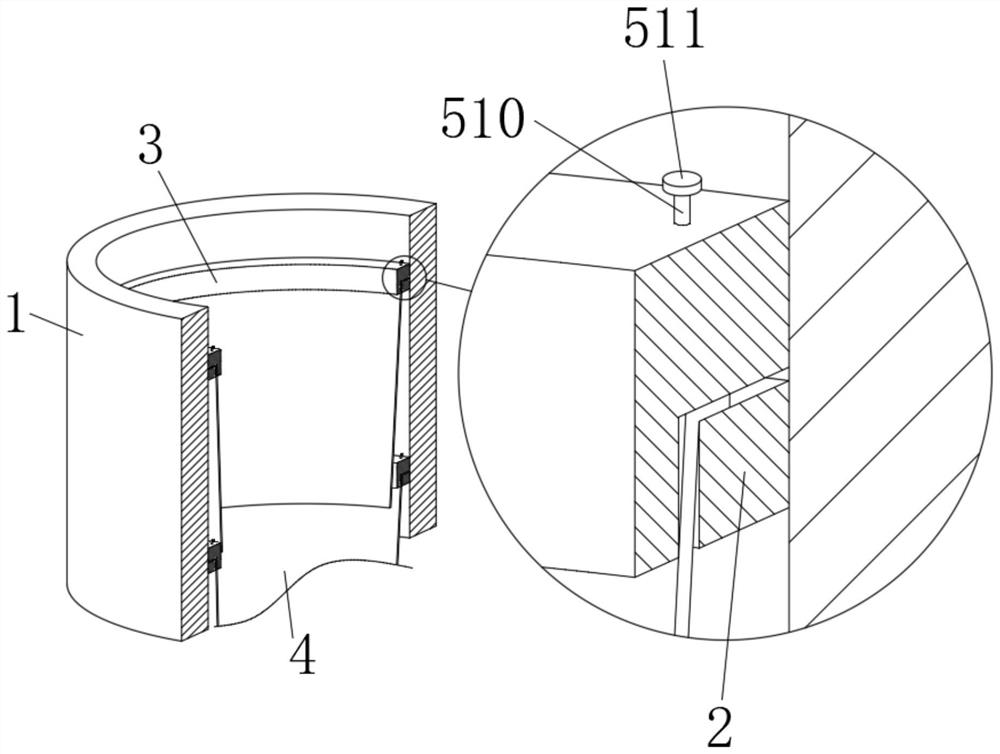

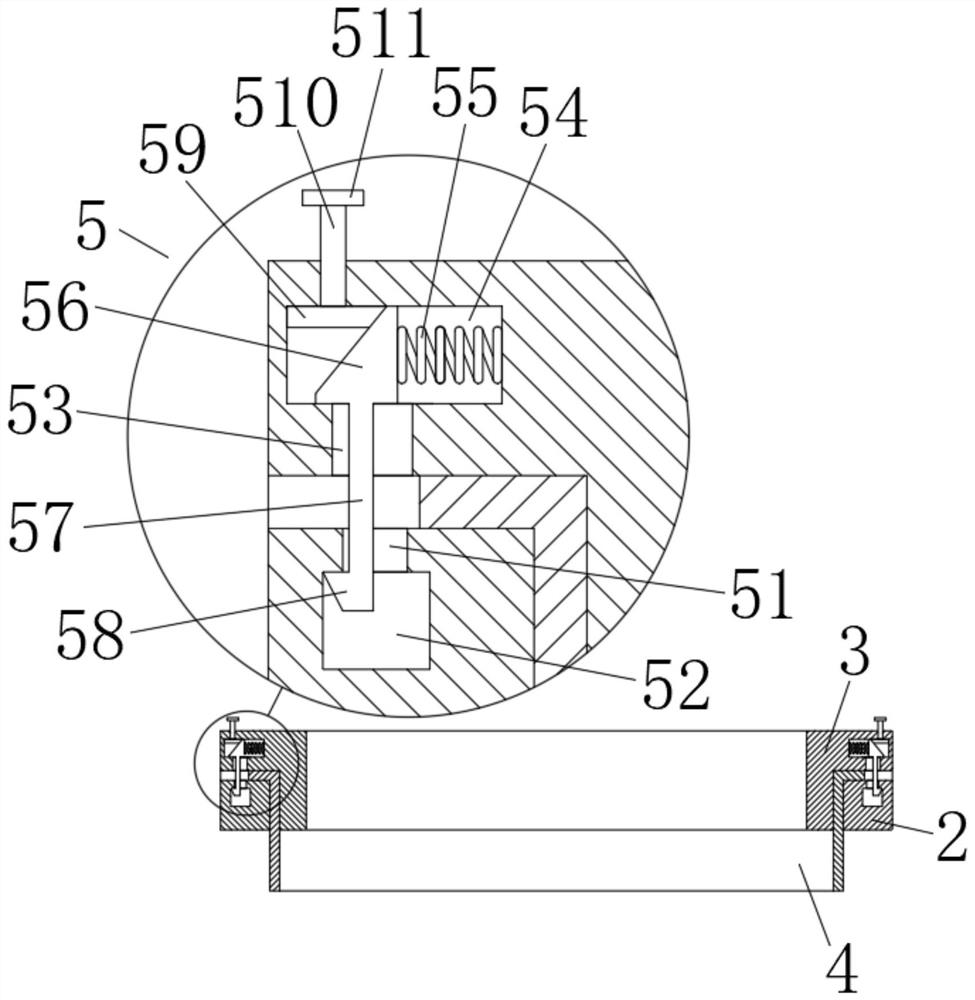

[0024] An anti-blocking device for a buffer silo, comprising a silo cylinder 1, the inner wall of the silo cylinder 1 is equidistantly fixedly connected with an annular flat iron 2, and the outer side of the annular flat iron 2 is in contact with the inner wall of the silo cylinder 1 fit; the top of the annular flat iron 2 is clamped with an annular pressure plate 3, and the size of the annular pressure plate 3 matches the size of the annular flat iron 2; between the top of the annular flat iron 2 and the bottom of the annular pressure plate 3 Both are provided with a plastic film 4, through the cooperation between the annular flat iron 2 and the annular pressure plate 3, it is convenient to better compress the plastic film 4; It is covered in fish scales in turn. When installing the plastic film 4, it can be installed from the bottom of the silo body 1, and the top of the plastic film 4 is pressed by the cooperation between the annular flat iron 2 and the annular pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com