Speed reducer for punching machine

A technology of reducer and stamping machine, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of complex structure of planetary reducer, unfavorable installation and maintenance, and prolonging the installation and debugging time of reducer, etc., to achieve The effect of simple structure, large torque and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below are specific embodiments of the present invention and in conjunction with accompanying drawing, technical scheme of the present invention is described further, but the present invention is not limited to these embodiments.

[0027] like Figure 1 to Figure 5 As shown, in this solution, the reduction gear is mainly described in detail for the punching machine, but the reduction gear of the present invention is not limited to the application in the reduction gear, as long as it includes a motor drive device, it can be used, such as cars etc.

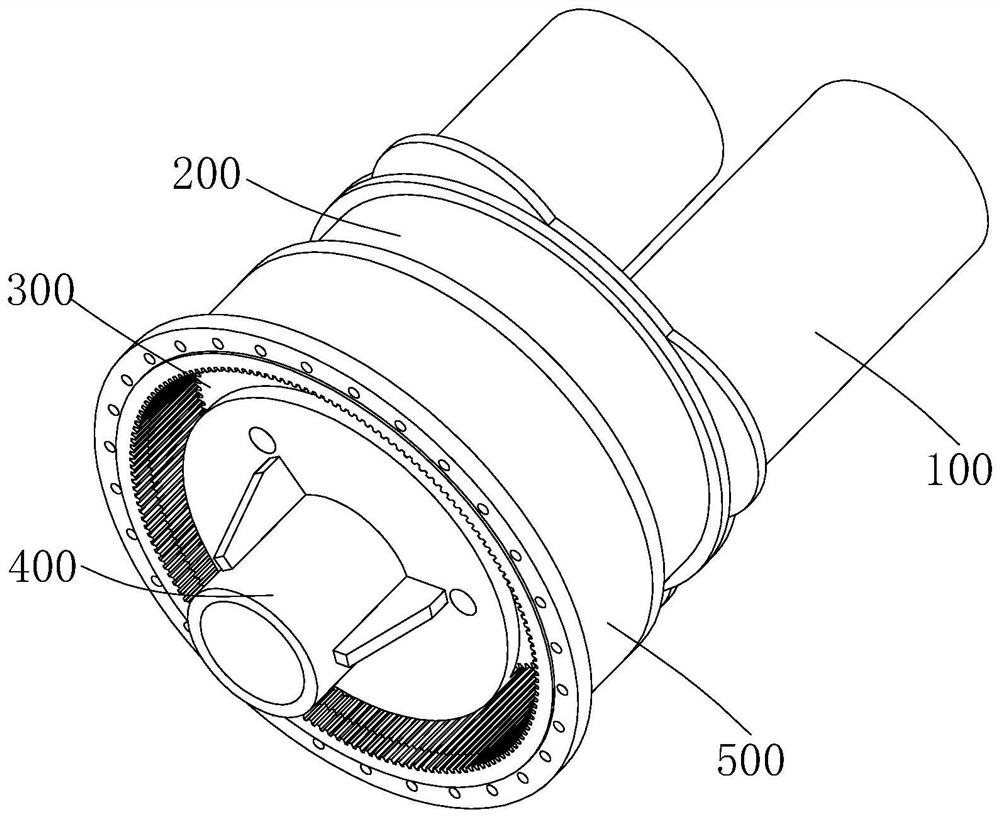

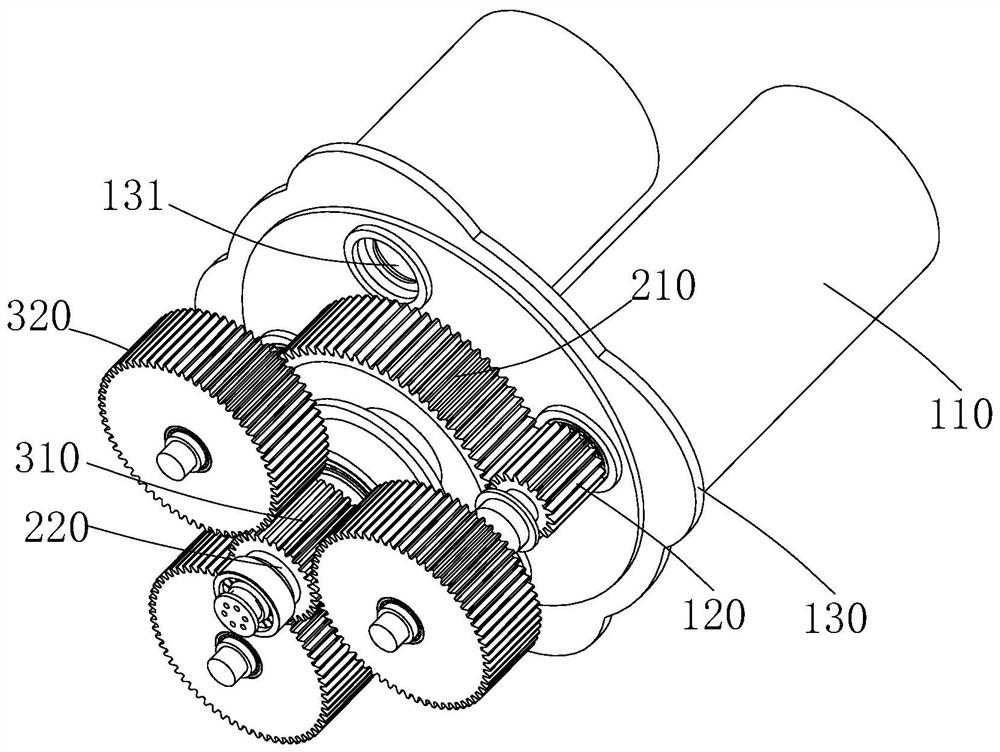

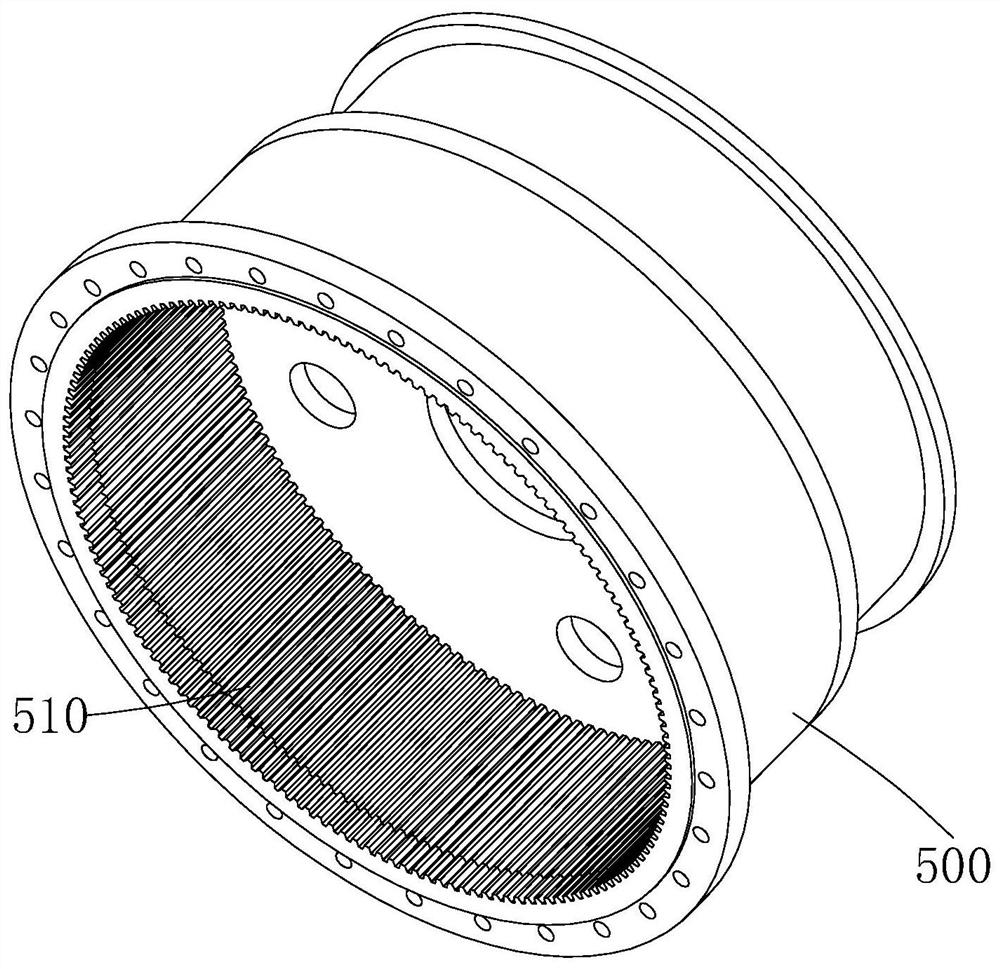

[0028] A speed reducer for a stamping machine of the present invention includes: a power input mechanism 100, a primary speed reduction mechanism 200, a secondary speed reduction mechanism 300 and a power output mechanism 400.

[0029] The power input mechanism 100 is detachably provided with several driving motors 110, and the output end of each driving motor 110 is provided with a main gear 120, and the driving motor 110 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com