High-reliability sensitive component

A technology of reliability and components, applied in the field of high-reliability sensitive components, can solve the problems of unguaranteed accuracy, unguaranteed sensor position accuracy, difficult replacement, etc., and achieve the effect of preventing external dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 5 Shown:

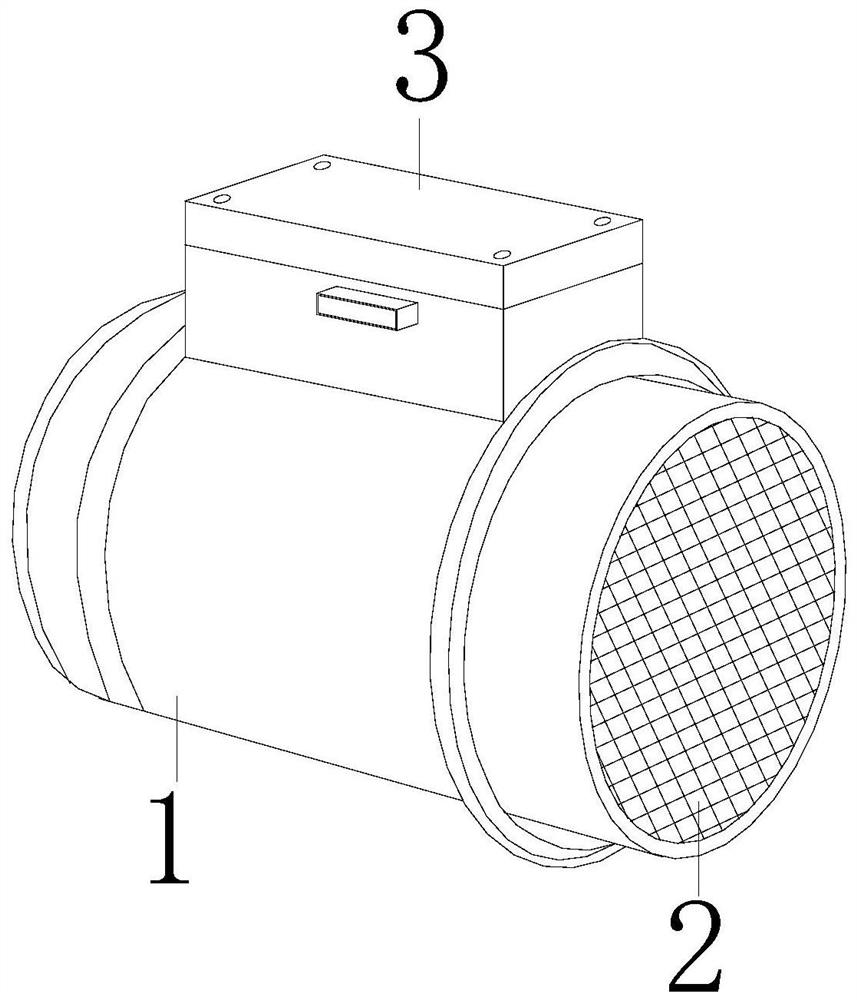

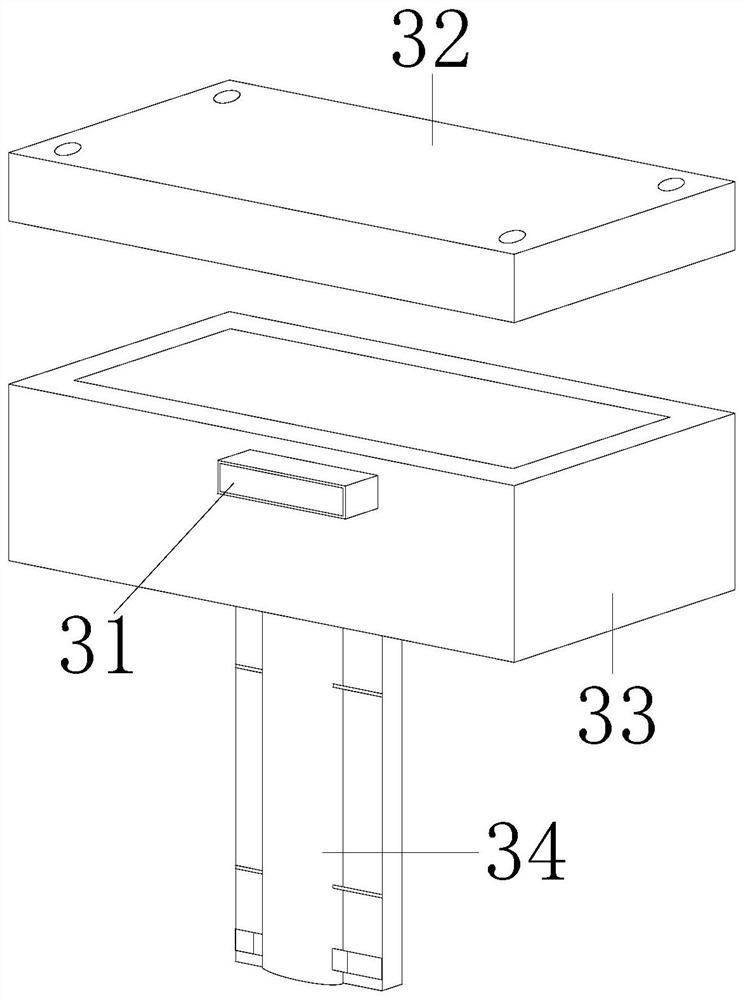

[0025] The present invention provides a high-reliability sensitive component, the structure of which includes a cylinder body 1, a filter screen 2, and a sensor device 3, the filter screen 2 is arranged in the middle of the right side of the cylinder body 1, and the sensor device 3 is installed Above the barrel 1, the sensor device 3 is composed of a signal interface 31, a cover plate 32, a protective shell 33, and a fixing mechanism 34. The rear end of the signal interface 31 is engaged with the protective shell 33, and the lower end of the cover plate 32 is connected to the The upper end of the protective shell 33 is connected by bolts, and the fixing mechanism 34 is arranged inside the protective shell 33 .

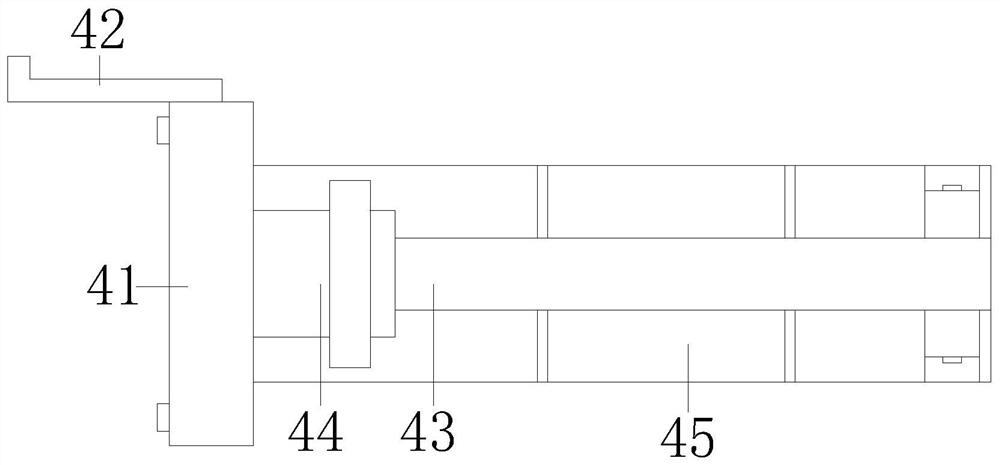

[0026] Wherein, the fixing mechanism 34 is composed of a conversion element 41, an adapter circuit 42, a small-diameter section 43, a large-diameter section 44, and a position support mechanism 45. The bottom ...

Embodiment 2

[0032] as attached Figure 6 to attach Figure 7 Shown:

[0033] Wherein, the hoop mechanism 54 is composed of a snap ring 4a, an adjustment mechanism 4b, a fixed nut 4c, and a rubber pad 4d, the rubber pad 4d is arranged inside the snap ring 4a, and the bottom of the snap ring 4a is mechanically connected with the adjustment mechanism 4b , the adjustment mechanism 4b is mechanically connected with the fixed nut 4c, the adjustment mechanism 4b is installed through the front end of the bottom plate 51, the rubber pad 4d is semi-enclosed, and is arranged inside the snap ring 4a to protect the large-diameter section 44 from being Snap ring 4a is damaged.

[0034] Wherein, the adjustment mechanism 4b is composed of a storage block b1, a recovery tank b2, an adjustment gear b3, and a rotating rod b4. The bottom end of the clasp 4a is set inside the recovery groove b2, and the recovery groove b2 is set in two, and the surface of the groove column is provided with a notch for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com