Fatigue crack identification method and system

A fatigue crack and identification method technology, applied in the field of fatigue crack identification methods and systems, can solve the problems of large workload of sample extraction, unrepresentative, and inability to identify fatigue cracks of structures to be measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

[0044] A fatigue crack identification method according to an embodiment of the present invention will be described below with reference to the accompanying drawings.

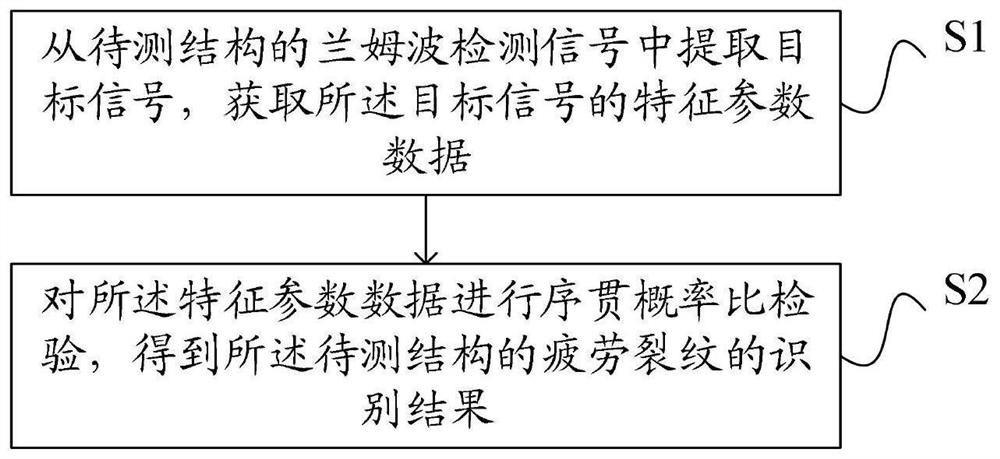

[0045] refer to figure 1 As shown, the present invention provides a fatigue crack identification method, comprising:

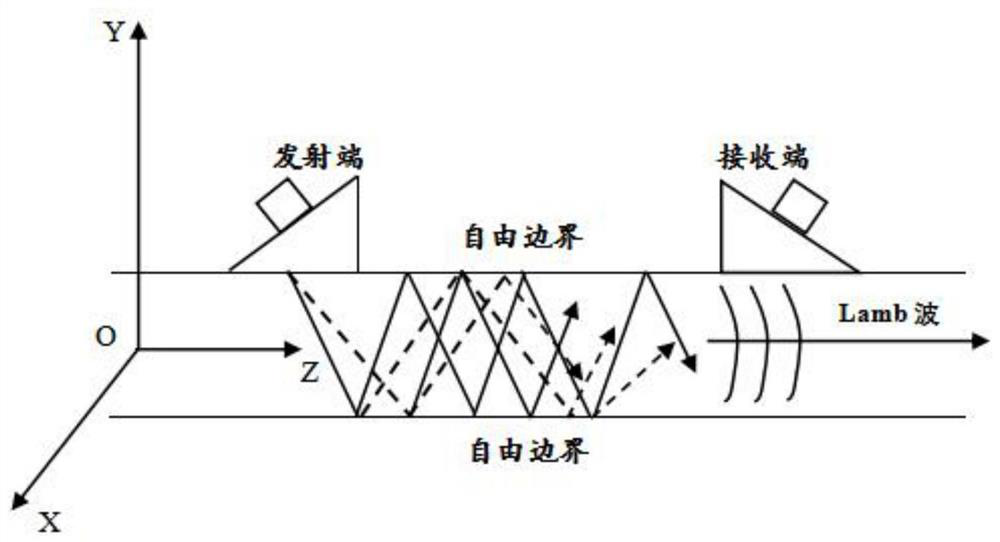

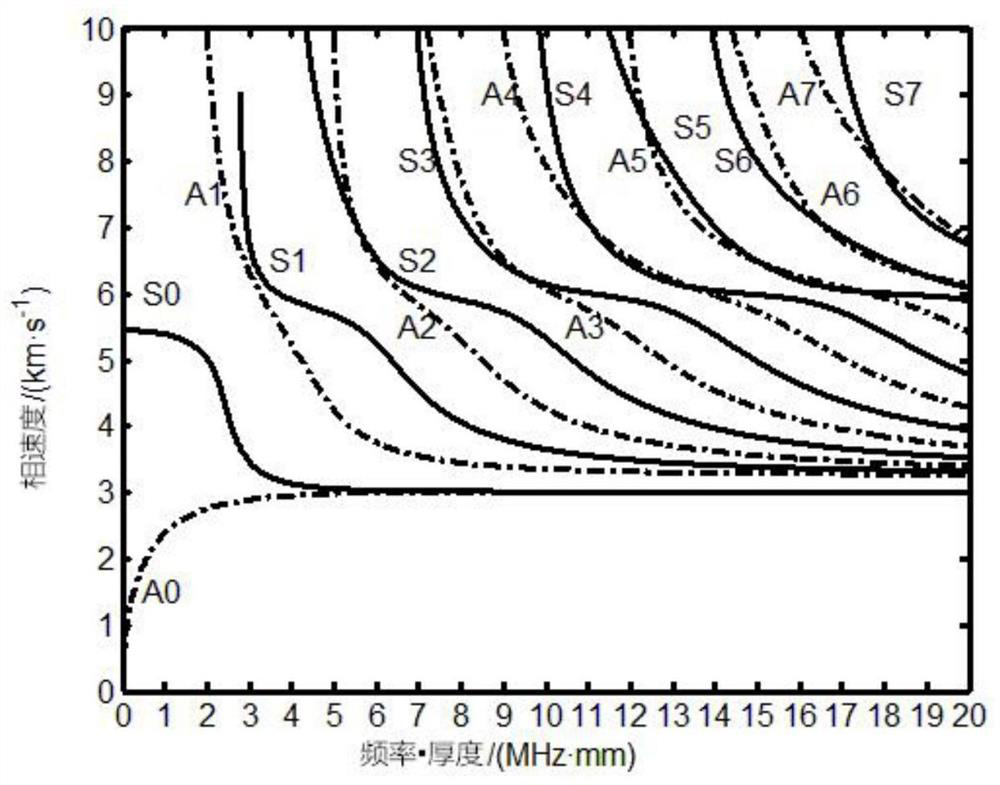

[0046] S1. Extract the target signal from the Lamb wave detection signal of the structure to be tested, and obtain the characteristic parameter data of the target signal;

[0047] S2. Performing a sequential probability ratio test on the characteristic parameter data to obtain an identification result of the fatigue crack of the structure to be tested.

[0048] The fatigue crack identification method provided by the above embodiment uses the characteristic parameter data to reflect the information characteristics of the fatigue crack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com