Construction waste classification treatment device

A technology for processing equipment and construction waste, applied in construction waste recycling, solid separation, filtering and other directions, can solve the problem of increasing labor force, save labor labor, and improve the efficiency of sorting and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

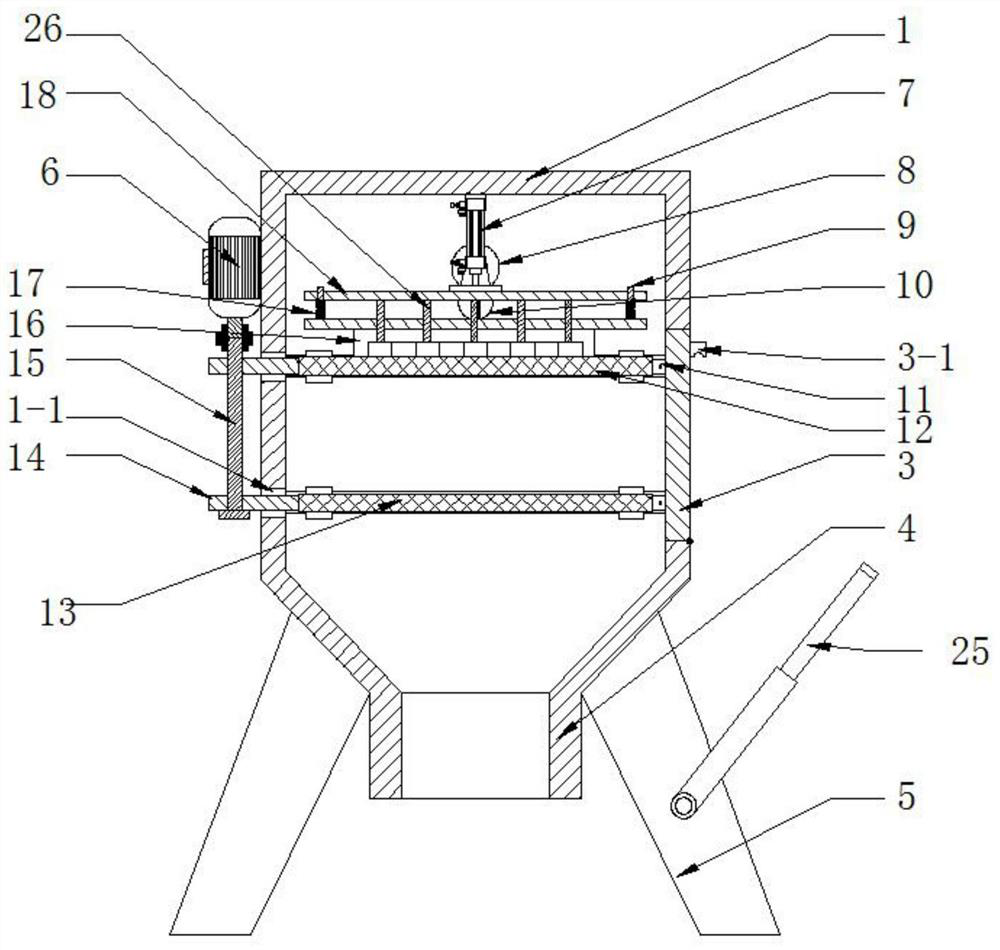

[0059] The difference between this specific embodiment and specific embodiment 1 is that: the cutting blade 16 includes a No. 1 blade 16-1 and a No. 2 blade 16-2; the No. 1 blade 16-1 is symmetrical to the No. 2 blade 16-2 Set, and the bottom edge side of the No. 1 blade 16-1 and the No. 2 blade 16-2 is all inclined-plane settings; it also includes:

[0060] The blade sleeve shaft 23, the blade sleeve shaft 23 is set through the No. 1 blade 16-1 and the No. 2 blade 16-2, and the blade sleeve shaft 23 is arranged in the give way groove 20 on the bottom wall of the cutting blade fixing plate 20 -1, the two ends of the blade sleeve shaft 23 are fixed on the side wall of the relief groove 20-1;

[0061] Blade extension spring 24, the quantity of described blade extension spring 24 is several, two by two is a group, and left and right is symmetrically sleeved on the same blade sleeve shaft 23.

[0062] The remaining components and connections are the same as those in the first emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com