Winding equipment with decontamination function for metal wire drawing process

A metal wire and decontamination technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of no longer cleaning function, limited use area, limited adsorption capacity, etc., to avoid Reduced cleaning effect, easy loading and unloading, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

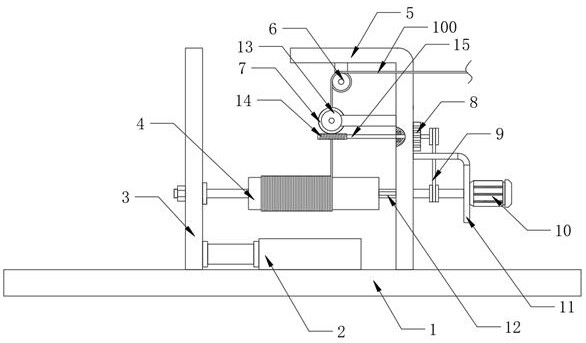

[0027] Such as figure 1 As shown, the present invention proposes a winding device for metal wire drawing process with cleaning function, comprising a base 1, on which a fixing plate 5 is arranged, and one side of the fixing plate 5 is connected with a drive through a mounting bracket 11. A motor 10, a movable plate 3 is slidably arranged on the base 1, a rewinding mechanism 4 for rewinding the metal wire 100 is arranged between the movable plate 3 and the fixed plate 5, and a driving rewinding mechanism is connected to the output shaft of the drive motor 10 4 rotating connecting shaft 12, two groups of cleaning mechanisms 7 for cleaning the metal wire 100 are also arranged on the fixed plate 5, and a power transmission mechanism for driving the two groups of cleaning mechanisms 7 to clean the metal wire 100, the connecting shaft 12 passes through the transmission The mechanism 9 drives the power transmission mechanism to the cleaning mechanism 7 .

[0028] The working princip...

Embodiment 2

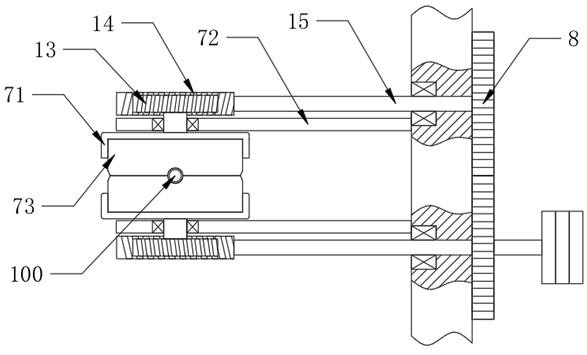

[0030] Such as Figure 1-2 As shown, the present invention proposes a winding device for wire drawing process with cleaning function. Compared with Embodiment 1, the cleaning mechanism 7 in this embodiment includes a support plate 72 fixed on the fixed plate 5 , the support plate 72 is connected with a bearing housing 71 through a rotating shaft, and a cleaning member 73 is arranged in the bearing housing 71, combined with Figure 6 As shown, the inner side of the carrying case 71 is provided with a baffle, which can prevent the relative rotation between the cleaning part 73 and the carrying case 71, refer to Figure 5 As shown, the surface of the cleaning piece 73 preferably adopts uniform protrusions; of course, the surface of the cleaning piece 73 can also be a plane, and the cleaning piece 73 completely covers the metal wire 100;

[0031] The power transmission mechanism includes a horizontal shaft 15 rotatably mounted on the fixed plate 5, a worm screw 14 is fixed at one...

Embodiment 3

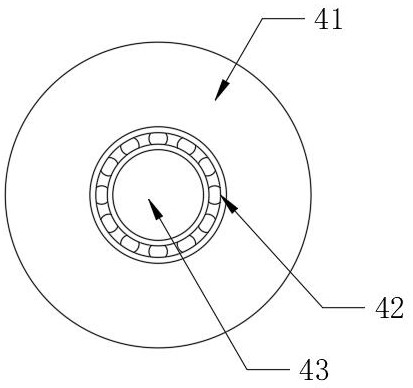

[0035] Such as figure 1 and image 3 and Figure 4 As shown, the present invention proposes a rewinding device for the metal wire drawing process with a cleaning function. Compared with Embodiment 1 or Embodiment 2, the rewinding mechanism 4 in this embodiment includes a wire 100 with A reel 41 wound in sequence, one side of the reel 41 is provided with a connecting groove 44, the other side of the reel 41 is provided with a bearing 42, the inner ring of the bearing 42 is fixed with a fixed shaft 43, and the other side of the fixed shaft 43 One end runs through the movable panel 3;

[0036] The fixed shaft 43 is provided with a shielding portion and a threaded portion on one side of the shielding portion, the threaded portion of the movable plate 3 passes through the movable plate 3 and is screwed with a nut;

[0037] One end of the connecting shaft 12 close to the winding mechanism 4 matches the shape and size of the connecting groove 44;

[0038] The base 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com