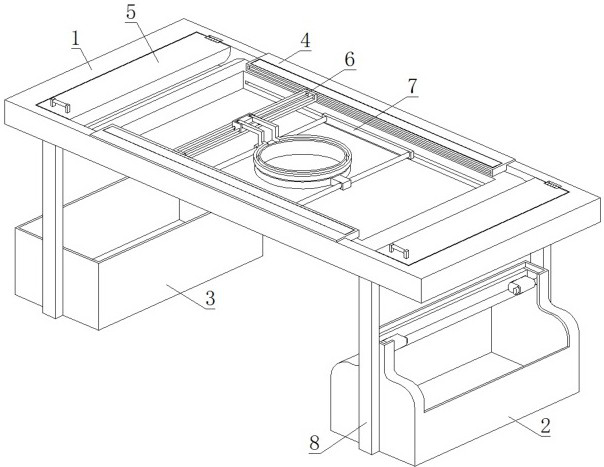

Fishing net tension adjusting and repairing device and operation method for fishing net machine

A tension and fishing net machine technology is applied in the field of fishing net tension adjustment and repair devices, which can solve the problems of large floor space, unrestricted woven fishing net tension, influence of woven fishing net tension, etc. The effect of easy towing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

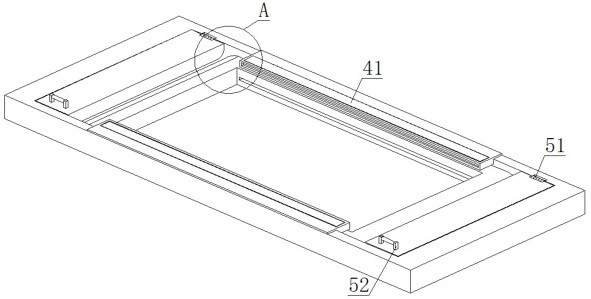

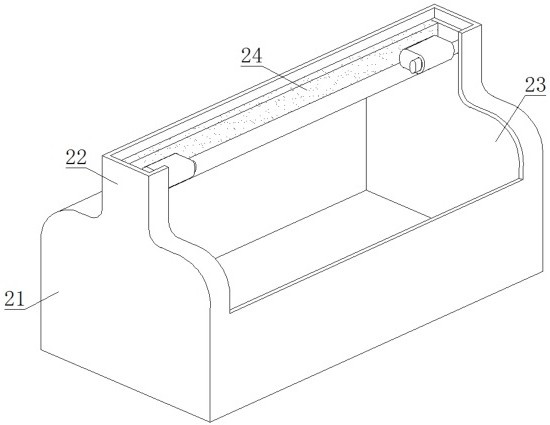

[0042] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for operating a fishing net tension adjustment and repairing device for a fishing net machine, comprising the following steps:

[0043] Step 1: Place the woven fishing net 9 that needs to be fully inspected in the narrow mouth discharge box 2, turn over the movable limit flap 5 at both ends through the hinge 51, so that the empty slots at both ends of the support pad 11 are exposed, and the woven fishing net One end of 9 passes through the fastener 24 and stretches into the empty groove at one end of the support pad frame 11, and the return spring 2434 is used to make the swing strip 2442 slide down along the arc bar 2433, so that the fastening clip 244 is relatively opposite to the rubber patch 242. Clamping the braided fishing net 9;

[0044] Step 2: Stretch into the woven fishing net 9 at the empty slot and extend the corners of both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com