Method for detecting dangerous goods by explosive-handling robot based on self-adaptive spatial feature fusion

An EOD robot and spatial feature technology, applied in the field of visual inspection, can solve problems such as low detection accuracy and slow detection speed, achieve good robustness, reduce deployment requirements, and reduce the amount of memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

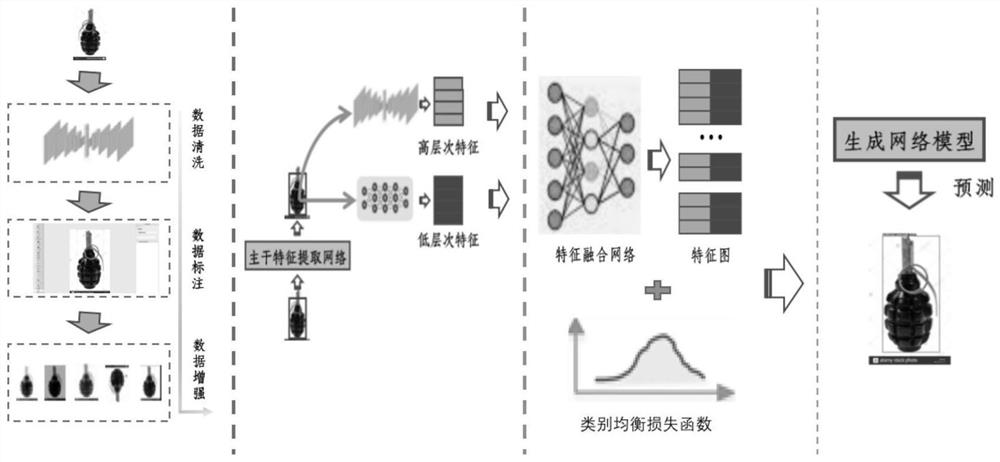

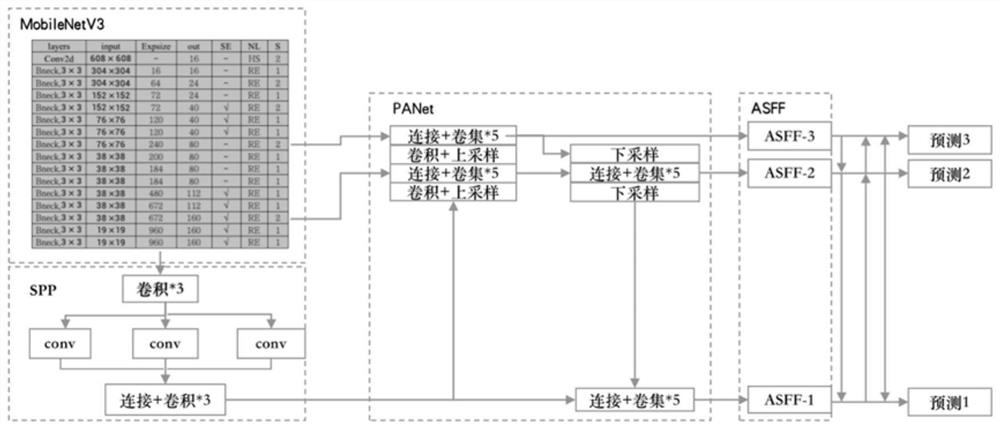

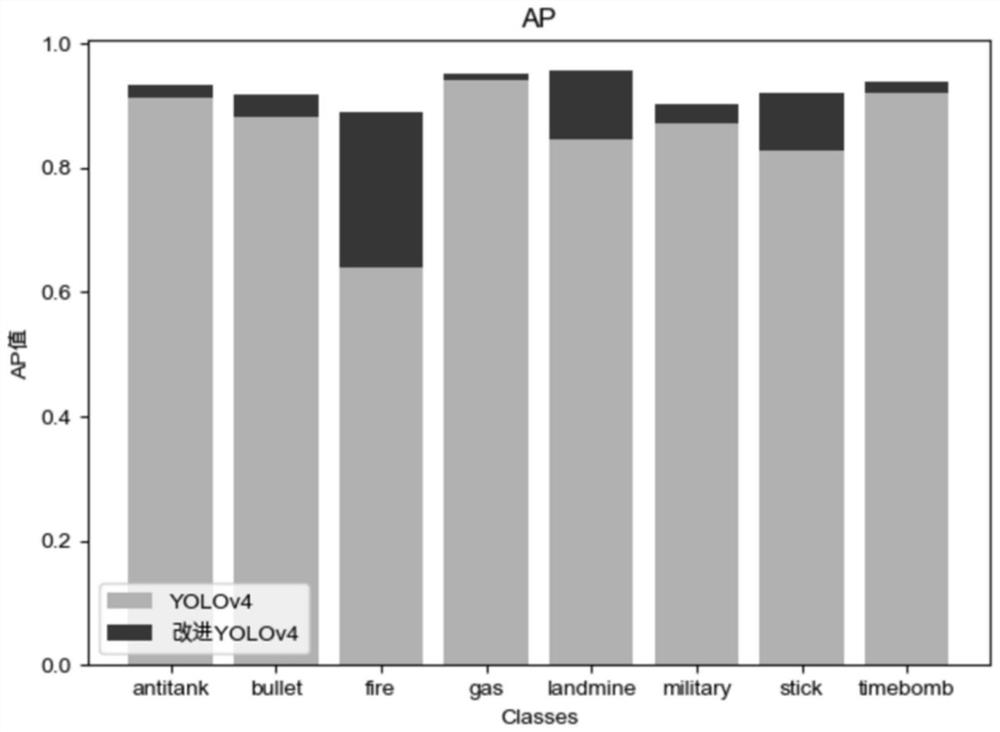

[0037] A dangerous goods detection method for an EOD robot based on adaptive spatial feature fusion, applied to electronic equipment, comprising the following steps:

[0038] (1) Construct a dangerous object data set:

[0039] (1.1) Obtain the initial dangerous object data set from the Internet crawling data, specifically: use the Scrapy framework of the python language to crawl the data on the Internet website by specifying keywords to obtain the initial dangerous object data set;

[0040] (1.2) After cleaning the initial dangerous object data set, label it, specifically: use the structural similarity index to remove the duplicate data in the initial dangerous object data set, and then use LabelImg visual graphic labeling software, according to the data of PASAL VOC2007 Annotate the image in the format of the set and store the generated XML file;

[0041] (1.3) Perform data enhancement on the marked data set to obtain the dangerous object data set, specifically: respectively...

Embodiment 2

[0056] An electronic device, including one or more processors, one or more memories, one or more programs, a data grabbing device for grabbing data from the Internet, and an image acquisition device for acquiring photos of objects to be tested;

[0057] One or more programs are stored in the memory, and when the one or more programs are executed by the processor, the electronic device executes the method for detecting dangerous goods of an EOD robot based on adaptive spatial feature fusion as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com