Antibacterial insole

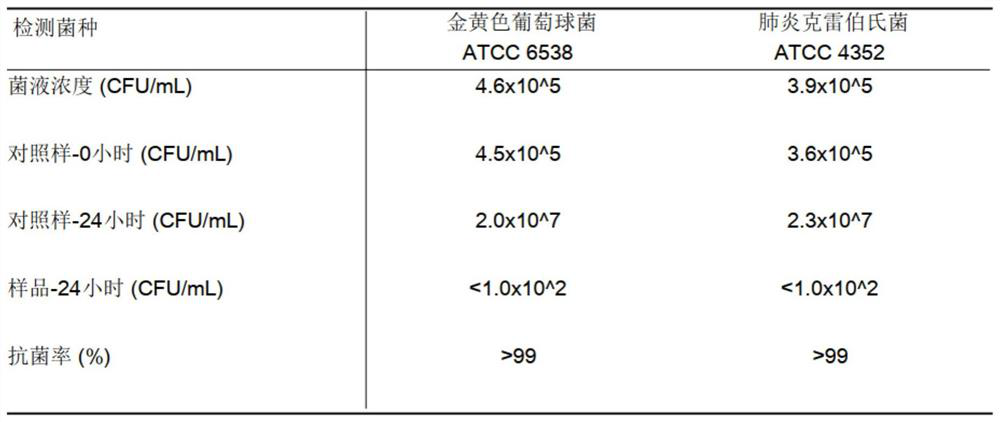

The technology of insole and antibacterial agent is applied in the field of insole design and manufacture, which can solve the problems of forefoot sliding, poor air permeability, poor slip resistance, etc., and achieve the effects of preventing foot odor, good slip resistance and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

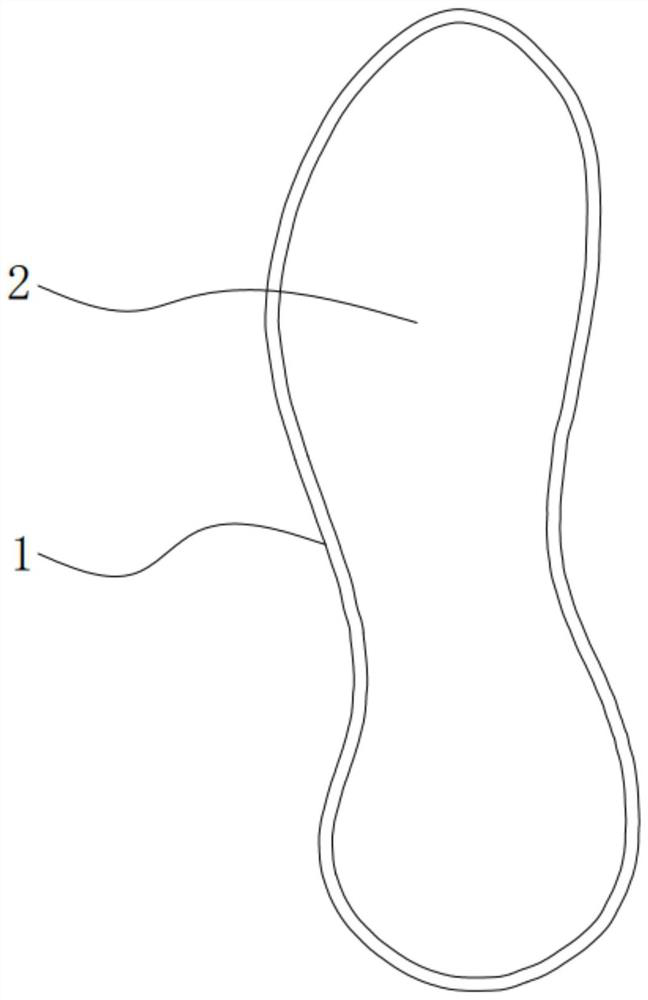

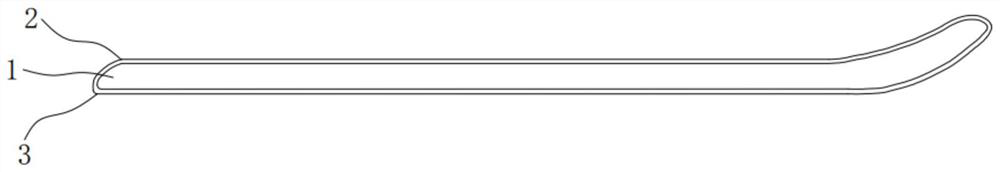

[0030] Please refer to the attached Figure 1~2 , in the embodiment of the present invention, a kind of antibacterial insole, comprises interlining 1, and the bamboo charcoal antibacterial coating 2 that is loaded on interlining 1, by mass parts, bamboo charcoal antibacterial coating 2 comprises the bamboo charcoal powder of 10~30 parts, 100 1-5 parts of ether polyurethane, 1-5 parts of catalyst, 1-5 parts of melting agent, 1-5 parts of hardener, 1-3 parts of water and 40-70 parts of isocyanate; bamboo charcoal antibacterial coating 2 also The antibacterial agent is included, the mass fraction of the antibacterial agent is 1-3 parts, and the antibacterial agent is silicon dioxide.

[0031] In a preferred embodiment of the present invention, the bamboo charcoal antibacterial coating 2 includes 10 parts of bamboo charcoal powder, 100 parts of ether polyurethane, 1 part of catalyst, 1 part of melting accelerator, 1 part of hardener, 1 part of water, 40 parts isocyanate and 1 par...

Embodiment 2

[0035] Please refer to the attached Figure 1~2 , in the embodiment of the present invention, a kind of antibacterial insole, comprises interlining 1, and the bamboo charcoal antibacterial coating 2 that is loaded on interlining 1, by mass parts, bamboo charcoal antibacterial coating 2 comprises the bamboo charcoal powder of 10~30 parts, 100 1-5 parts of ether polyurethane, 1-5 parts of catalyst, 1-5 parts of melting agent, 1-5 parts of hardener, 1-3 parts of water and 40-70 parts of isocyanate; bamboo charcoal antibacterial coating also includes The antibacterial agent, the mass fraction of the antibacterial agent is 1-3 parts, and the antibacterial agent is silicon dioxide.

[0036] In a preferred embodiment of the present invention, the bamboo charcoal antibacterial coating 2 includes 20 parts of bamboo charcoal powder, 100 parts of ether polyurethane, 2 parts of catalyst, 1 part of melting accelerator, 2 parts of hardener, 1 part of water, 60 parts isocyanate and 2 parts ...

Embodiment 3

[0040] Please refer to the attached Figure 1~2 , in the embodiment of the present invention, a kind of antibacterial insole, comprises interlining 1, and the bamboo charcoal antibacterial coating 2 that is loaded on interlining 1, by mass parts, bamboo charcoal antibacterial coating 2 comprises the bamboo charcoal powder of 10~30 parts, 100 1-5 parts of ether polyurethane, 1-5 parts of catalyst, 1-5 parts of melting agent, 1-5 parts of hardener, 1-3 parts of water and 40-70 parts of isocyanate; bamboo charcoal antibacterial coating also includes The antibacterial agent, the mass fraction of the antibacterial agent is 1-3 parts, and the antibacterial agent is silicon dioxide.

[0041] In a preferred embodiment of the present invention, the bamboo charcoal antibacterial coating 2 includes 30 parts of bamboo charcoal powder, 100 parts of ether polyurethane, 5 parts of catalyst, 5 parts of melting accelerator, 5 parts of hardener, 3 parts of water, 70 parts isocyanate and 3 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap