An anesthetic gas purification device

A technology for exhaust gas purification device and anesthetic gas, which is applied in the field of air purification device in anesthesia department, can solve the problems of threatening the life, health and safety of medical staff of patients, low utilization rate of filter materials, and increase of anesthetic gas content, so as to avoid unqualified filtration, The effect of reducing the content of anesthetic gas and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

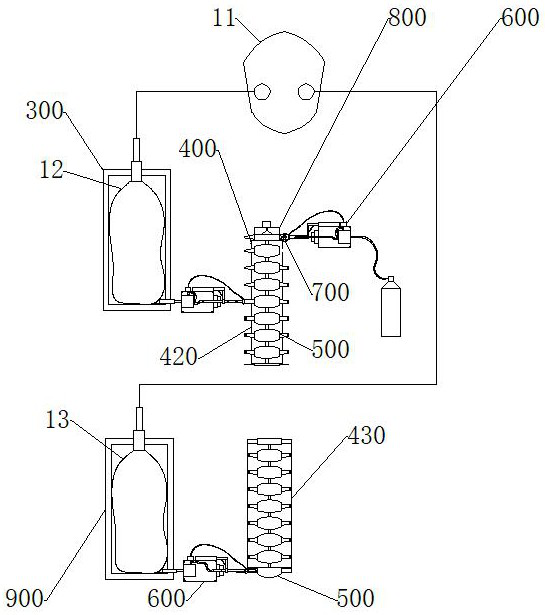

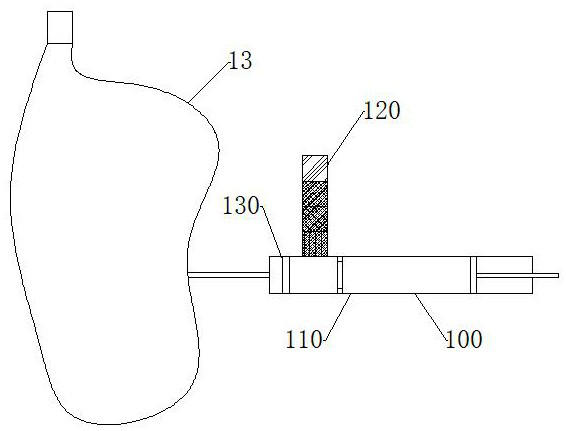

[0084] In the actual use process, it was found that the filtration of exhaled gas requires very high continuous processing capacity of the filter material. During the use process, it is very difficult to achieve complete filtration, and there is still the problem of leakage. Therefore, the handling of anesthetic gases is designed for storage of exhaled gases such as Figure 2-8 .

[0085] The gas exhaled by the patient is stored in a unit first, and after being stored by the unit airbag 500, the exhaled gas can be stored first, and then extracted for filtering operation, and the final elimination of anesthetic gas is carried out. In this way, the harmful gas with anesthetic components exhaled by the patient can not be filtered in the operating room to avoid the leakage of exhaled gas. Meanwhile, the form of the unit airbag 500 is convenient for storage and subsequent operation. If it is a large storage bag, the volume of exhaled gas is relatively large, and it is very inconv...

Embodiment 3

[0089] During the preparation of anesthetic gas, the actual active ingredient should be mixed with air and inhaled by the patient. If only one air bag, that is, the first air storage soft bag 12 is used for buffering, the actual inhalation uniformity of the anesthetic gas will be affected by the first storage soft bag. The size of the air soft bag, the intake velocity of anesthetic gas and air, the inhalation volume of the patient and the breathing rate will change. Therefore, the anesthetic gas that the patient needs to inhale is also unitized. The encapsulation operation of the gas can be the same as in the second embodiment, injecting the same amount of anesthetic gas and air into the unit airbag at the same time. Then the air in the unit airbag 500 is input into the first soft bag 12 at a certain rate.

[0090] In actual use, air can be filled into the unit airbag 500 in advance, so that the inflation of the unit airbag 500 can only be filled with a fixed amount of anesth...

Embodiment 4

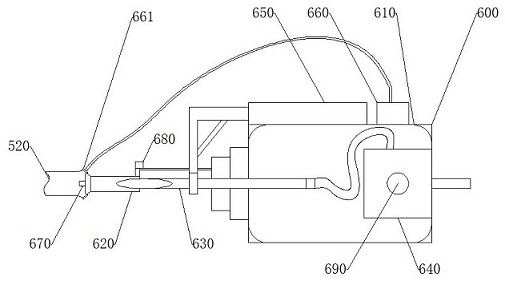

[0114] The delivery of the unit airbag 500 requires a relatively precise position and time interval. Therefore, the winding assembly 400 is added, such as figure 2 and 8 shown.

[0115] The winding assembly 400 is used for storing and delivering the unit airbag 500 group;

[0116] The winding assembly 400 includes a first roller 410, a second roller 420, and a third roller 430; the first roller 410, the second roller 420, and the third roller 430 are driven by a chain, a gear or a belt, and are driven by a stepping motor The transmission rotates synchronously;

[0117] The first roller 410 winds the group of unit airbags 500;

[0118] The second roller 420 undertakes the unit airbag 500 group on the first roller 410, and the third roller 430 undertakes the unit airbag 500 group on the second roller 420;

[0119] The unit airbags 500 on the first roller 410, the second roller 420, and the third roller 430 are continuous;

[0120] Driven by a stepping motor, the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com