Multidirectional vibration ultrasonic transducer, ultrasonic cleaning device and cleaning method

An ultrasonic transducer and ultrasonic cleaning technology, applied to chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems such as incomplete cleaning, cleaning dead ends, single vibration direction, etc., to achieve thorough cleaning , avoid standing wave, high vibration frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

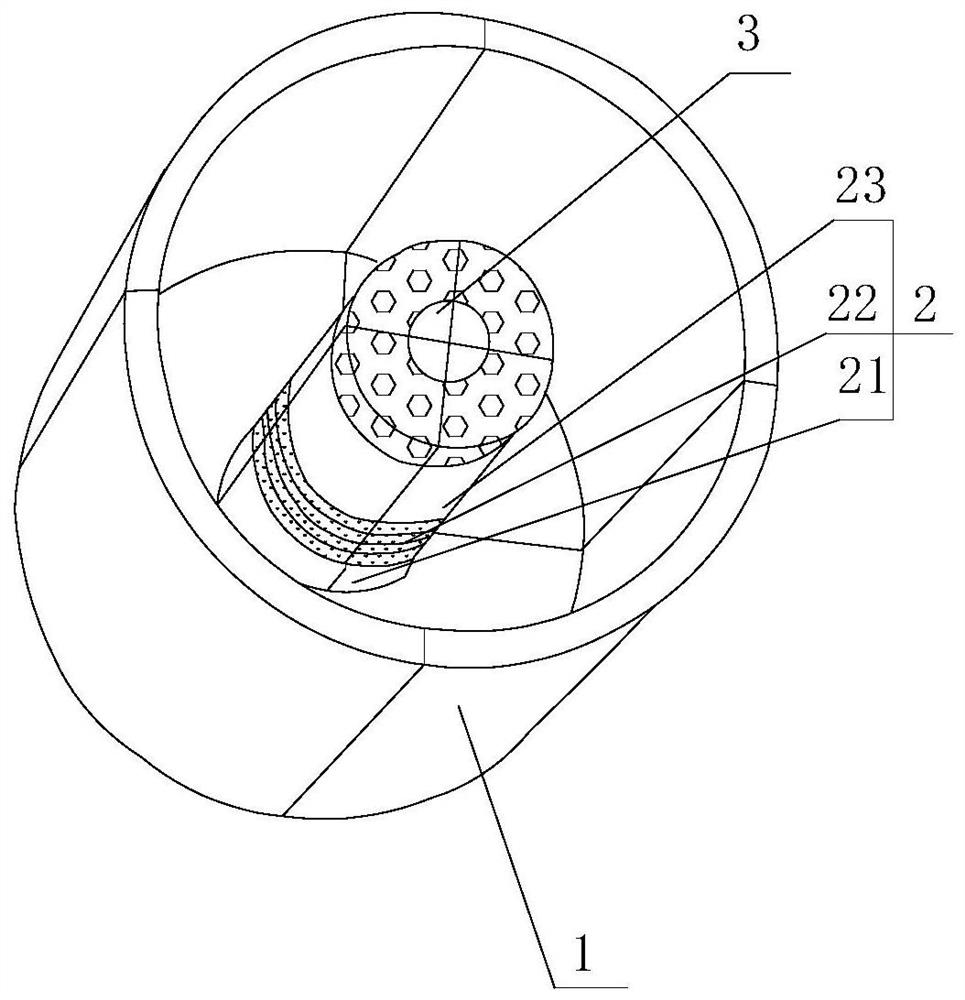

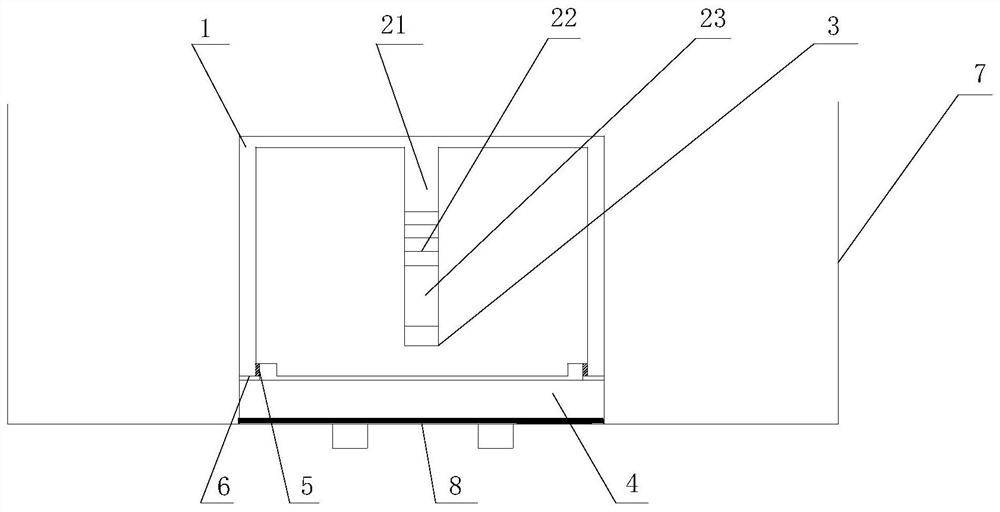

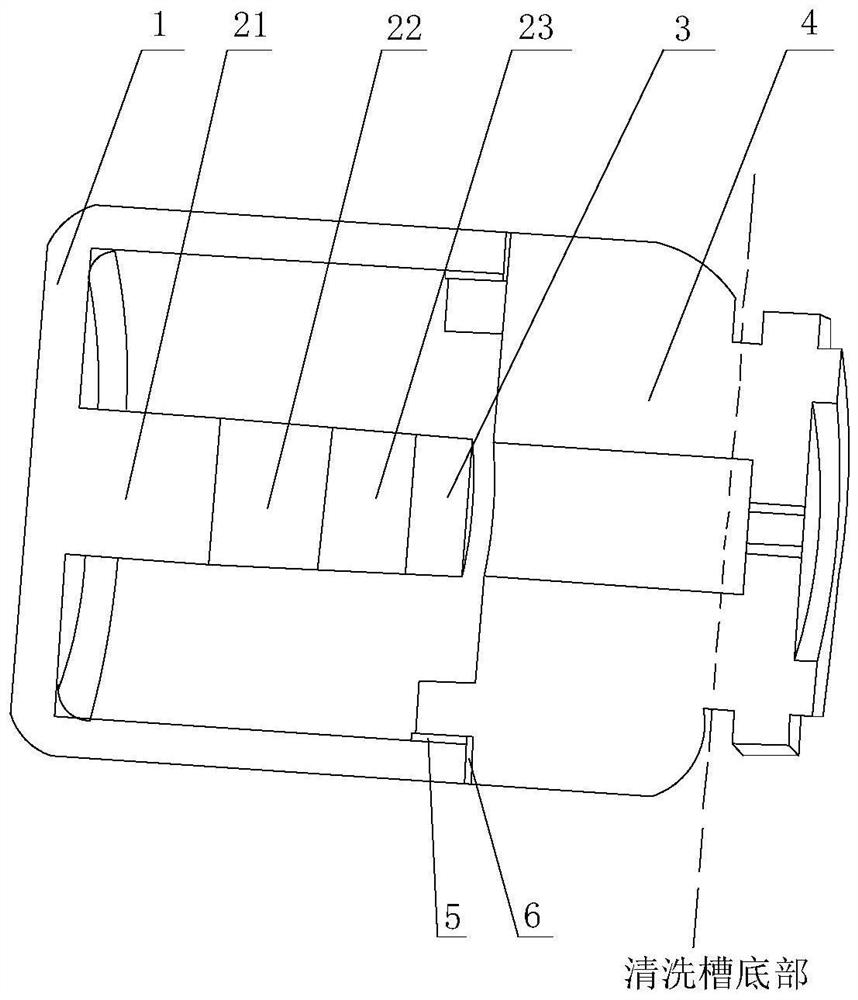

[0031] see figure 1 and figure 2 The ultrasonic transducer with multi-directional vibration provided in this embodiment includes a base 4, a vibrating cover 1 and a vibrating column 2 arranged in the inner cavity of the vibrating cover 1; a sealing vibration isolation layer is arranged between the vibrating cover 1 and the base 4; the vibrating cover 1 is a hollow cylindrical structure, which is inverted on the base 4 and connected with the base 4 to form a closed cavity structure. The top of the vibrating column 2 is connected to the center of the vibrating cover 1, and the vibrating column 2 is excited to generate vibration and transmit it to the vibrating cover 1 , through the vibrating cover 1 radiates a synthetic vibration formed by longitudinal axisymmetric bending vibration and radial transverse vibration alternately.

[0032] In this embodiment, the vibrating cover 1 is a hollow cylindrical structure, and the inner diameter R of the vibrating cover 1 is 15 mm; the de...

Embodiment 2

[0046] see figure 2 and image 3 The ultrasonic cleaning device provided in this embodiment includes the ultrasonic transducer and the cleaning tank 7 provided in Embodiment 1; the base 4 of the ultrasonic transducer vibrating in multiple directions is fixed at the bottom center of the cleaning tank 7; The vibrating cover 1 of the ultrasonic transducer vibrating in the direction extends into the cleaning tank 7, through the vibrating cover 1 radiates into the cleaning tank 7 the composite vibration formed by the longitudinal axisymmetric bending vibration and the transverse vibration along the radial direction alternately, so that the cleaning tank 7, a stable radiation sound field composed of transverse vibration and bending vibration is formed.

[0047] In this embodiment, a waterproof gasket 8 is provided at the connection position between the base 4 of the ultrasonic transducer vibrating in multiple directions and the bottom of the cleaning tank 7 . Specifically, the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com