Device for installing leather cups of brake master cylinder and brake wheel cylinder and identifying whether leather cups are installed reversely

A technology for brake wheel cylinders and brake master cylinders, which is applied in the direction of manufacturing tools, color TV parts, TV system parts, etc., can solve the problems of low efficiency of the cups, and it is difficult to ensure that the cups are not installed backwards. Achieve the effect of saving time and effort for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

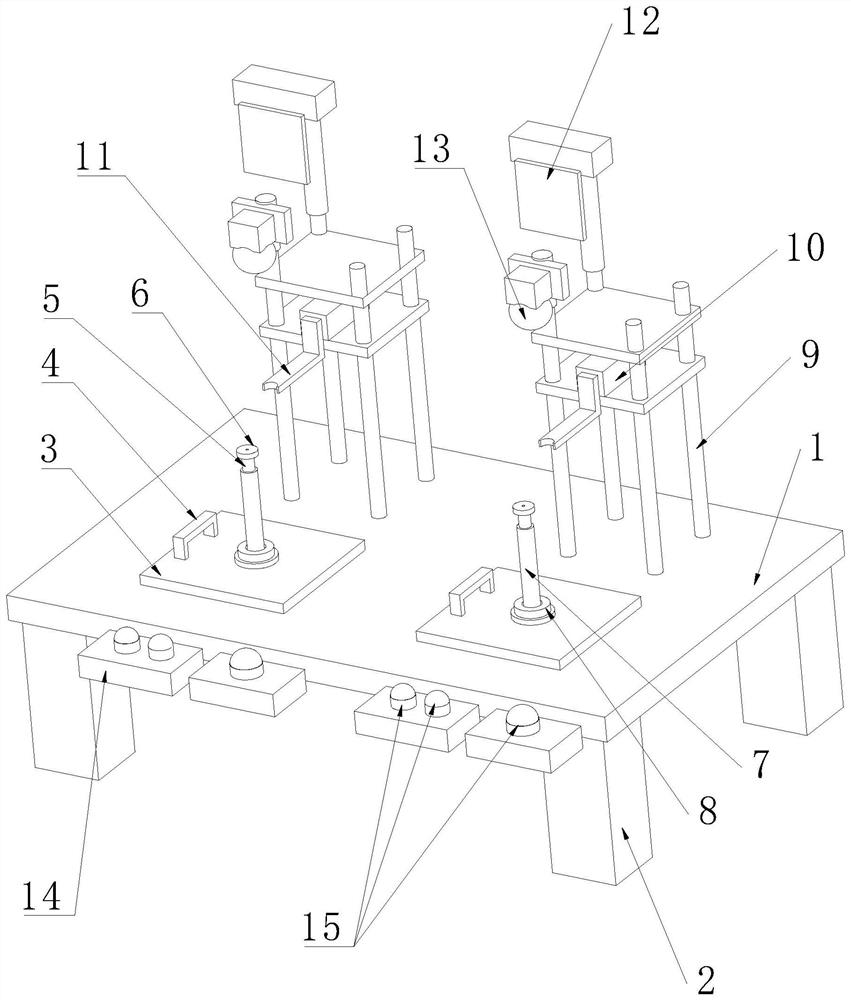

[0013] Such as figure 1 As shown, the present invention proposes a device for installing brake master cylinders, brake wheel cylinder cups and identifying whether they are reversed, including a workbench 1 and two groups of assembly stations arranged on the workbench 1; the assembly station It includes a base 3, a support column 5, a top column 6, a sleeve 7, a cup groove adjustment block 8, a support frame 9, a first cylinder 10, a cup anti-drop block 11, a display 12, a camera 13 and a button support plate 14;

[0014] A plurality of sets of support legs 2 are arranged at the bottom of the workbench 1; a base 3 is arranged on the workbench 1, a circular plate is arranged on the base, and a sleeve 7 is vertically arranged on the circular plate; the support column 5 passes through the workbench 1, the base 3, The circular plate and the sleeve 7, the bottom of the workbench 1 is provided with a second cylinder that drives the support column 5 to move up and down; the top column...

Embodiment 2

[0018] The invention proposes a device for installing the brake master cylinder, the brake wheel cylinder cup and identifying whether it is reversed. Compared with the first embodiment, the base 3 is provided with a handle 4, which is convenient for lifting the base 3 and installing it on the workbench. 1 on.

Embodiment 3

[0020] The present invention proposes a device for installing brake master cylinders, brake wheel cylinder cups and identifying whether they are reversed. The installation and disassembly are simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com