Practical pneumatic barrier gate mechanism

A gate and pneumatic technology, applied in the field of practical pneumatic gate mechanism, can solve the problems of increasing the operating load of the reducer, easy failure, and high noise, and achieve the effects of reducing power requirements, good wind resistance, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

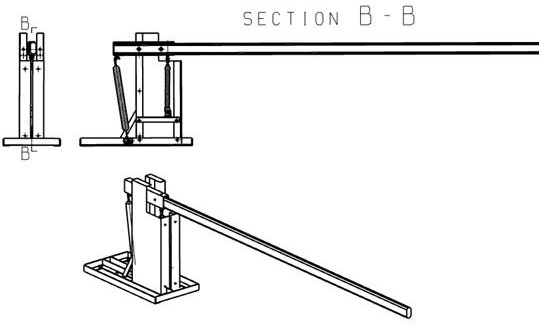

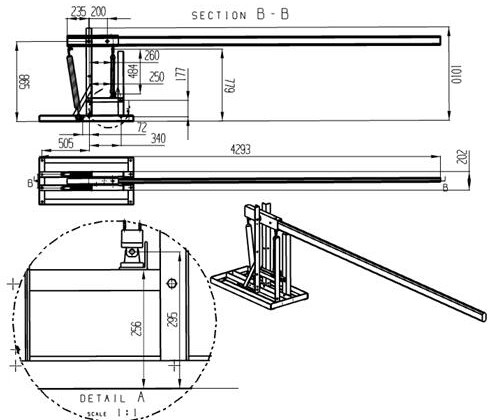

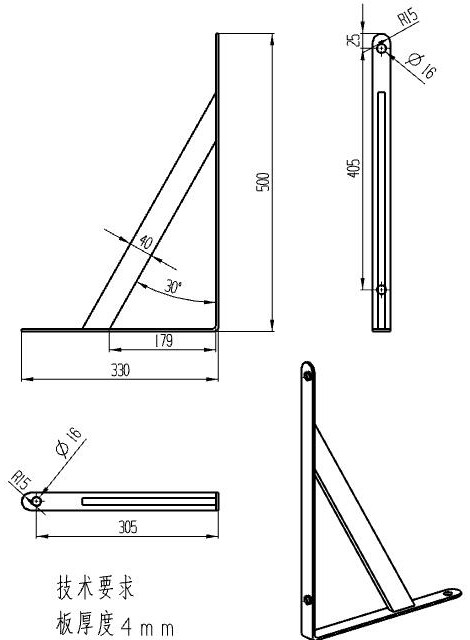

[0042] like Figure 18 As shown, the present invention provides a practical pneumatic barrier mechanism; figure 1 and figure 2 , one end of the aluminum barrier rod 5 is connected to the riser assembly 2 through the end face bearing 7; The fixed angle steel of the cylinder on the 2 is connected by screws, and the piston end is connected with the aluminum barrier rod 5 for driving the aluminum barrier rod 5 to turn over.

[0043]The first is the balance of the aluminum barrier bar 5. The right end of the aluminum barrier bar 5 protrudes 4 meters, nearly 5 kilograms per meter, and a total of nearly 20 kilograms. Its center of gravity is at a place of 2 meters, so it The moment arm is nearly 2 meters * 40 kg = 80 kilogram meters, that is, the balance of the left ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com