Rainwater leakage prevention structure for precast concrete external wall panel

A technology of prefabricated concrete slabs and prefabricated concrete, which is applied in the direction of building components, building structures, buildings, etc., and can solve the problems of poor water treatment effect and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution:

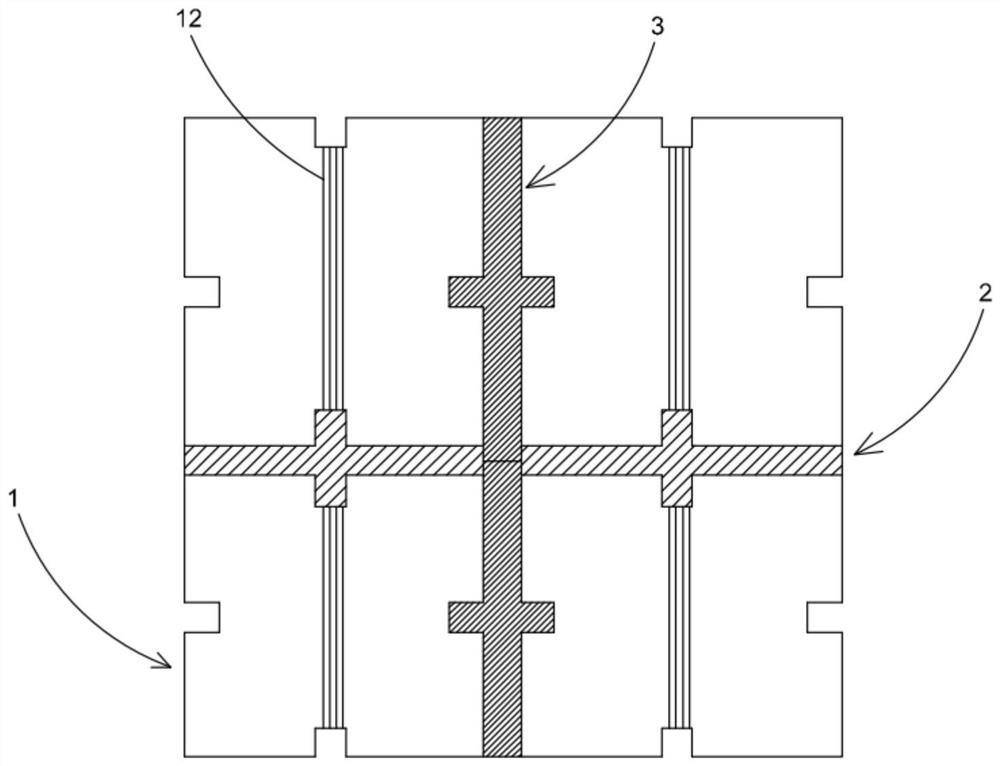

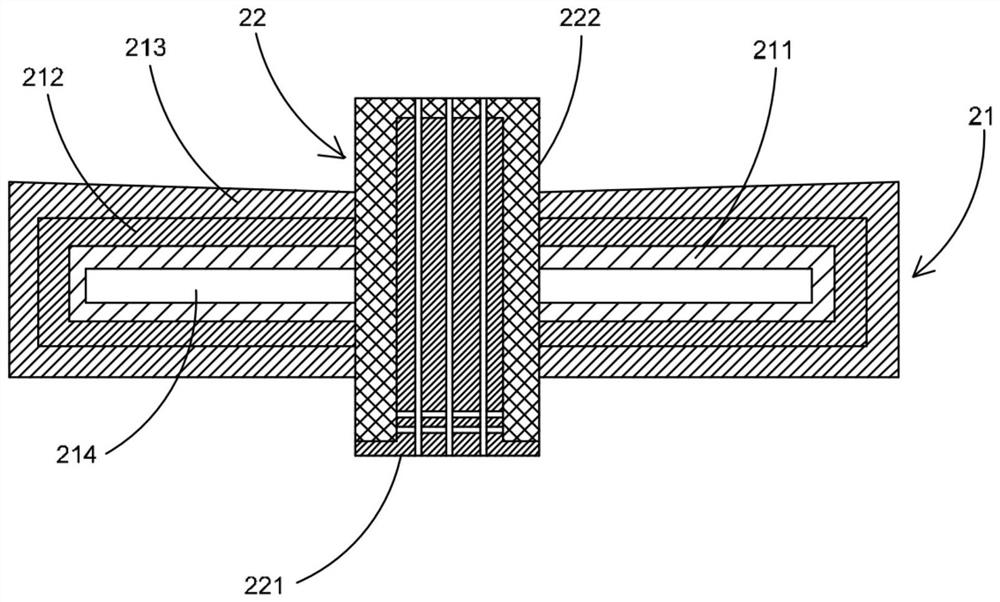

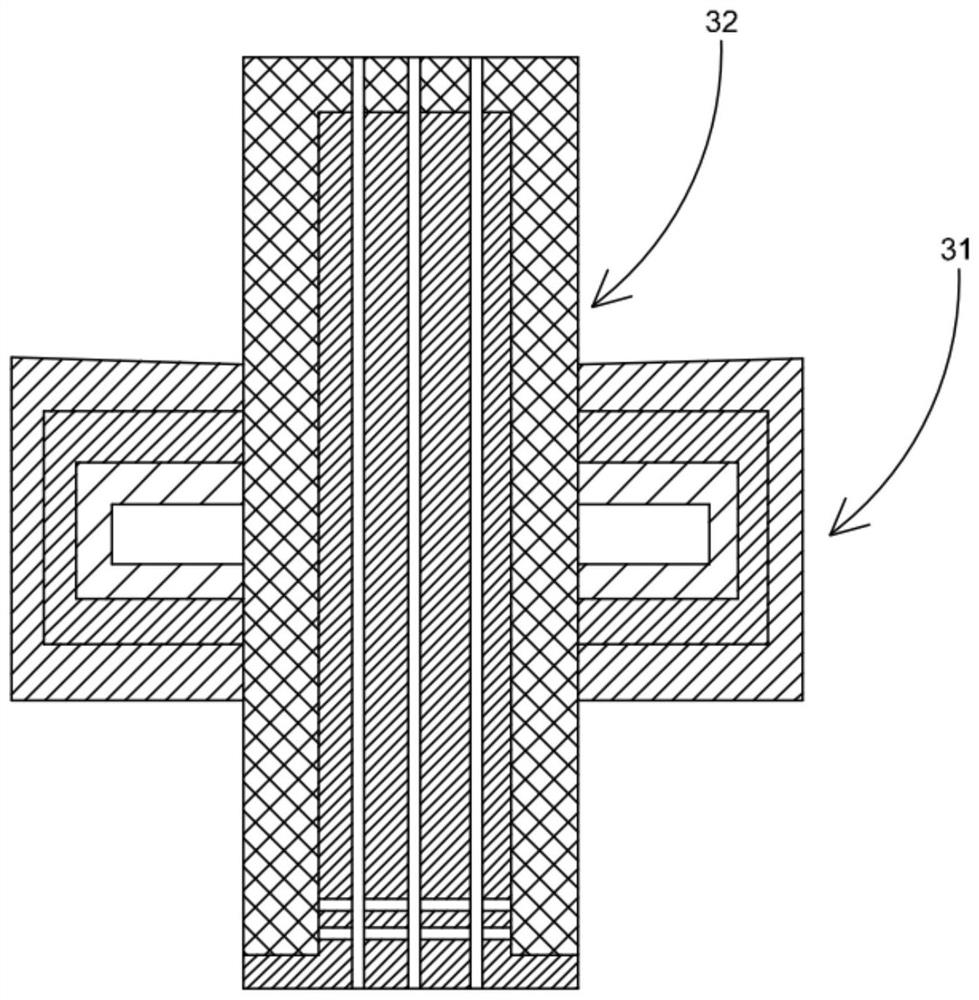

[0024] A rainwater leakage prevention structure for precast concrete exterior wall panels, the precast concrete exterior wall panels are composed of precast concrete panels 1 and structural members for supporting the precast concrete panels 1, the precast concrete panels 1 adjacent to each other above and below The intersection forms a horizontal separation joint, and the left and right adjacent precast concrete slabs 1 intersect to form a vertical separation joint. The horizontal separation joint is provided with a horizontal connector 2 for connecting the upper and lower adjacent precast concrete slabs 1, and the horizontal The connector 2 includes a water-resisting member I21 and a water-transporting member I22 arranged perpendicular to each other. When the upper and lower end faces of the water-resisting member I21 are closely connected with the upper and lower adjacent precast concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com