Belt tensioner

A tensioner and belt technology, applied in the field of vehicles, can solve the problems of long distance, reduced life, uneven friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

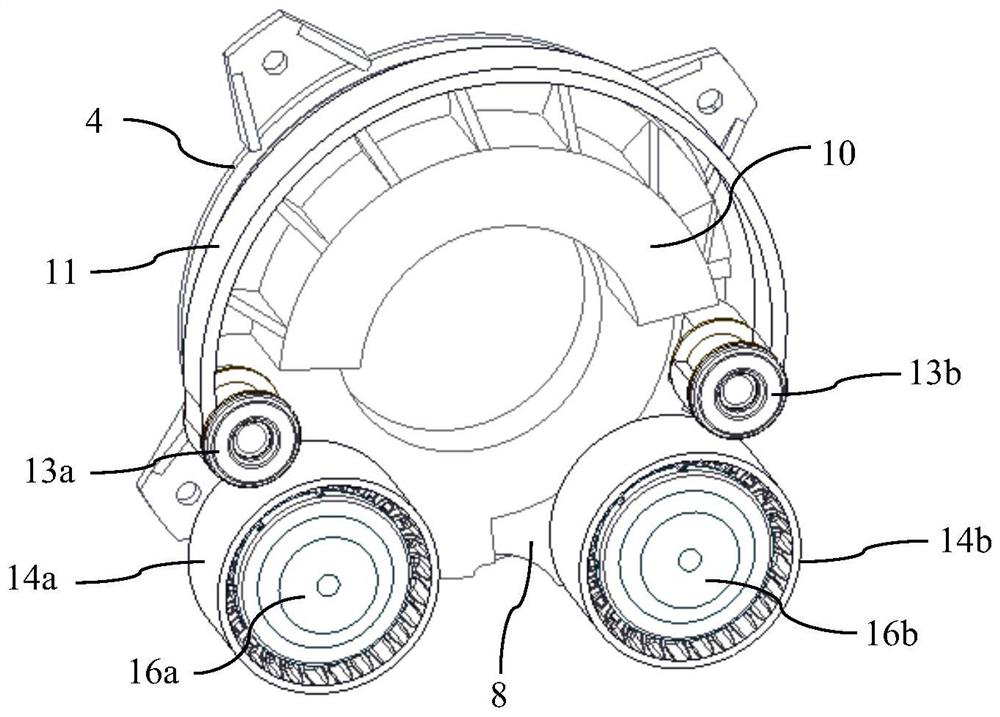

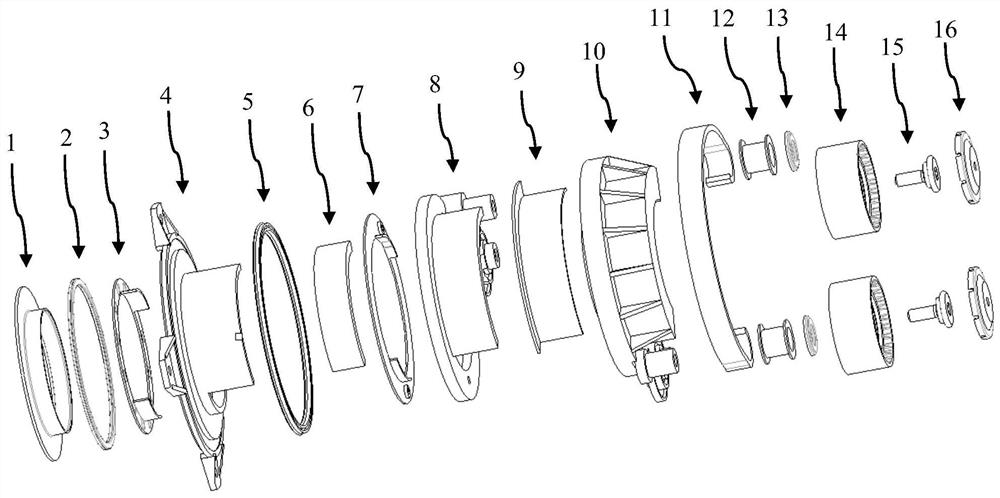

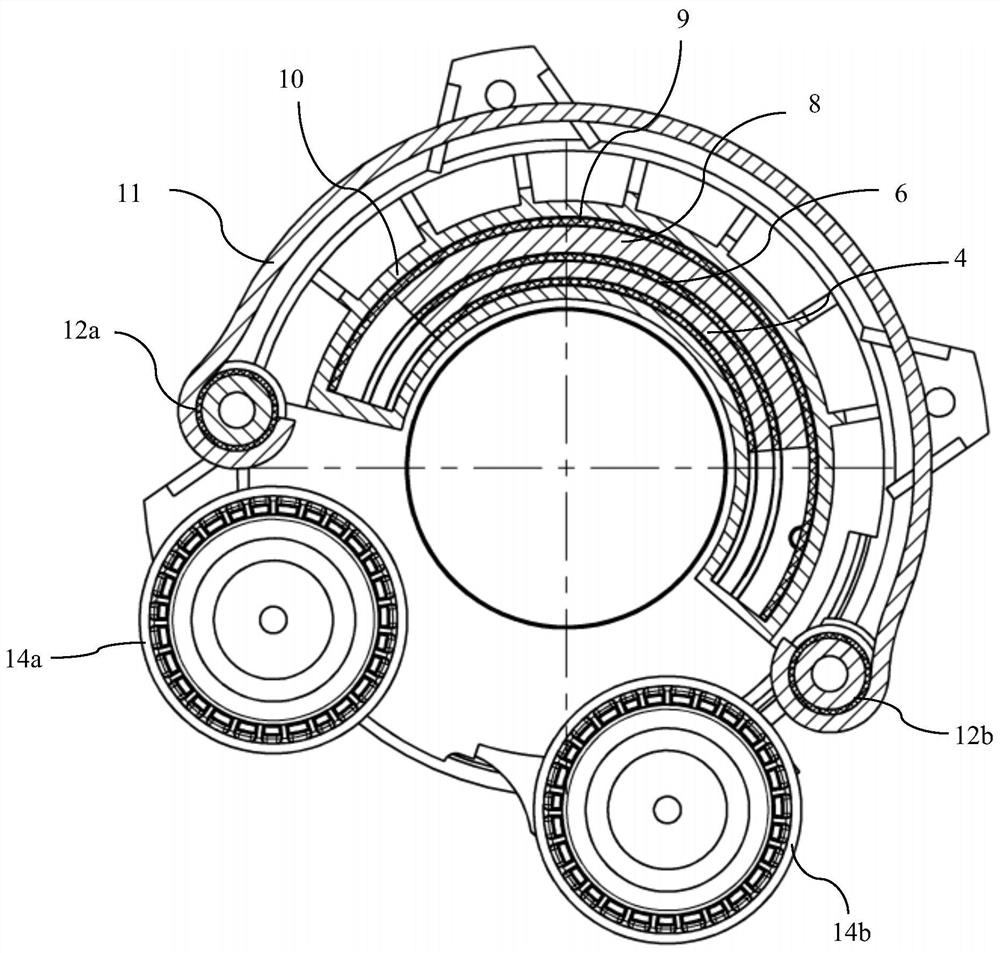

[0032] figure 1 with figure 2 A schematic perspective view and an exploded view of a belt tensioner according to a preferred embodiment are shown in each case. The belt tensioner can be used, for example, in a belt drive system in a hybrid vehicle, in particular a micro-hybrid vehicle. The belt drive can transmit power by means of its belt between the starter generator, the crankshaft of the internal combustion engine and the auxiliary equipment.

[0033] In this embodiment, the belt tensioner is mounted on the starter generator. to combine figure 1 with figure 2 It can be seen that the belt tensioner is formed overall as a ring, which can surround the motor shaft of the starter generator (not shown). The belt tensioner comprises a base element 4 , a first tensioning arm 10 , a second tensioning arm 8 and a spring element 11 . The base element 4 of the belt tensioner, the first tensioning arm 10 and the second tensioning arm 8 are each configured as a ring-shaped compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com