Fiber grating displacement sensor

A technology of displacement sensor and optical fiber grating, which is applied in the field of sensors, can solve the problems of easy fracture damage, poor applicability, vertical displacement, etc., and achieve the effects of wide application range, low cost and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

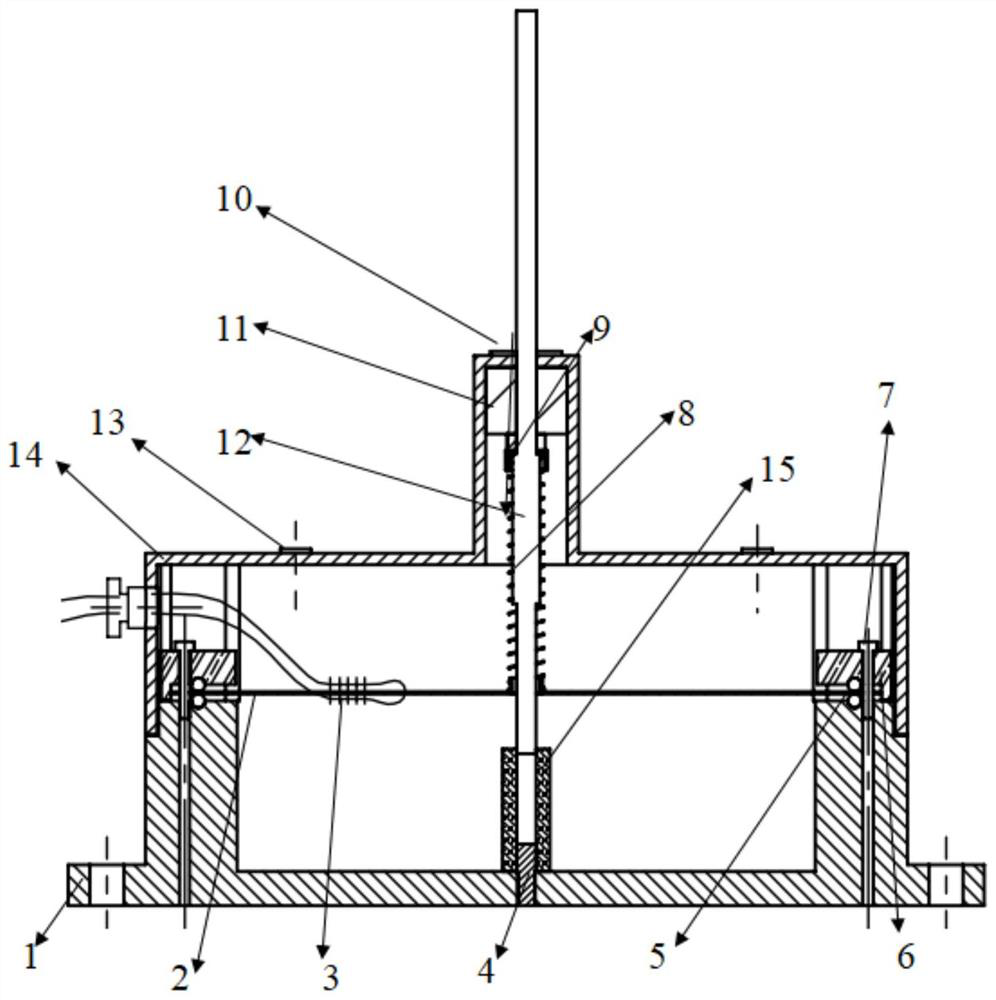

[0028] Attached below Figure 1-2 The present invention is further illustrated with specific examples.

[0029] Such as figure 1 As shown, a fiber grating displacement sensor, including:

[0030] The shell, the shell is divided into a base 1 and a top cover 14, the base 1 is a hollow structure and has an opening at one end, and the top cover 14 detachably encapsulates the opening of the base 1;

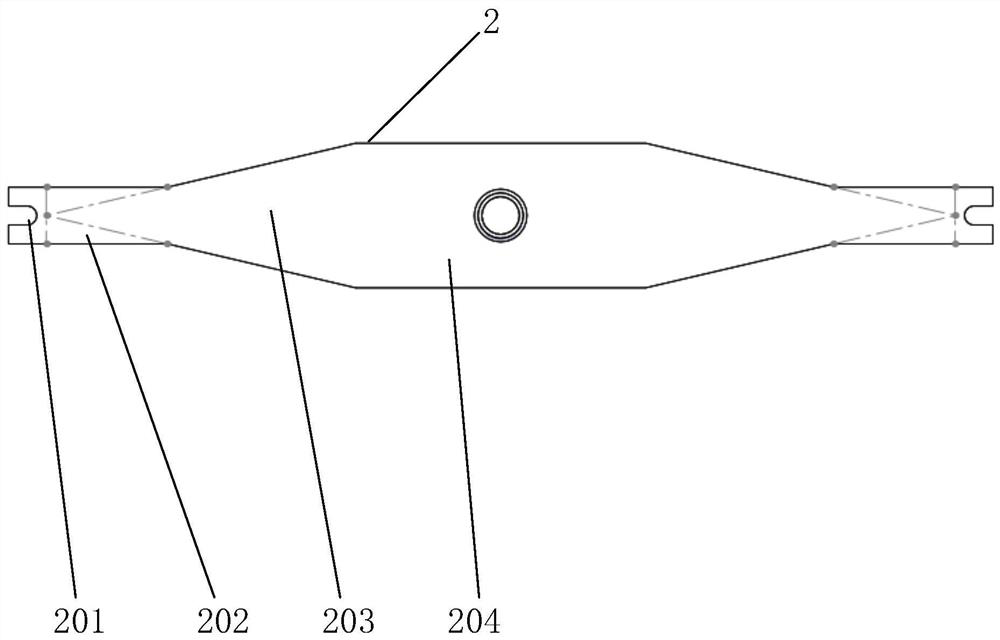

[0031] An elastic element 2 made of elastic material, the two ends of the elastic element 2 are installed on the base 1;

[0032] An axially arranged and slidable displacement measuring rod 12, the displacement measuring rod 12 axially passes through the top cover 14, a part of the displacement measuring rod 12 is in the inner cavity of the housing and passes through the middle part of the elastic element 2, and the other part extends out of the housing and rigging moving or deforming objects;

[0033] Spring 8, the spring 8 is set on the displacement measuring rod 12 and is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com