Method for producing charging pile cable by using composite flame retardant, and charging pile cable

A composite flame retardant and charging pile technology, applied in the direction of conductor/cable insulation, power cable with shielding layer/conductive layer, charging station, etc., can solve the problem that the charging cable cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

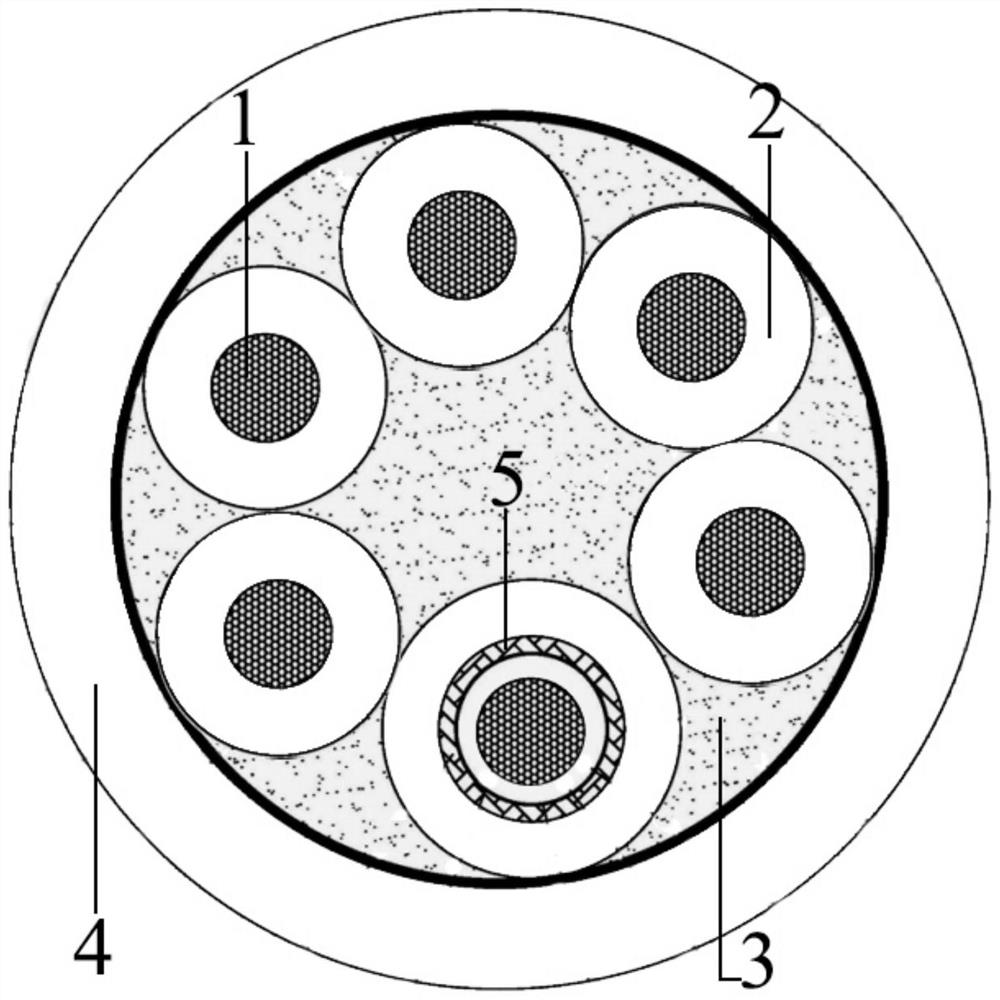

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

[0021] It should be noted that the steps shown in the flowcharts of the accompanying drawings may be performed in a computer system, such as a set of computer-executable instructions, and that although a logical order is shown in the flowcharts, in some cases, The steps shown or described may be performed in an order different than here.

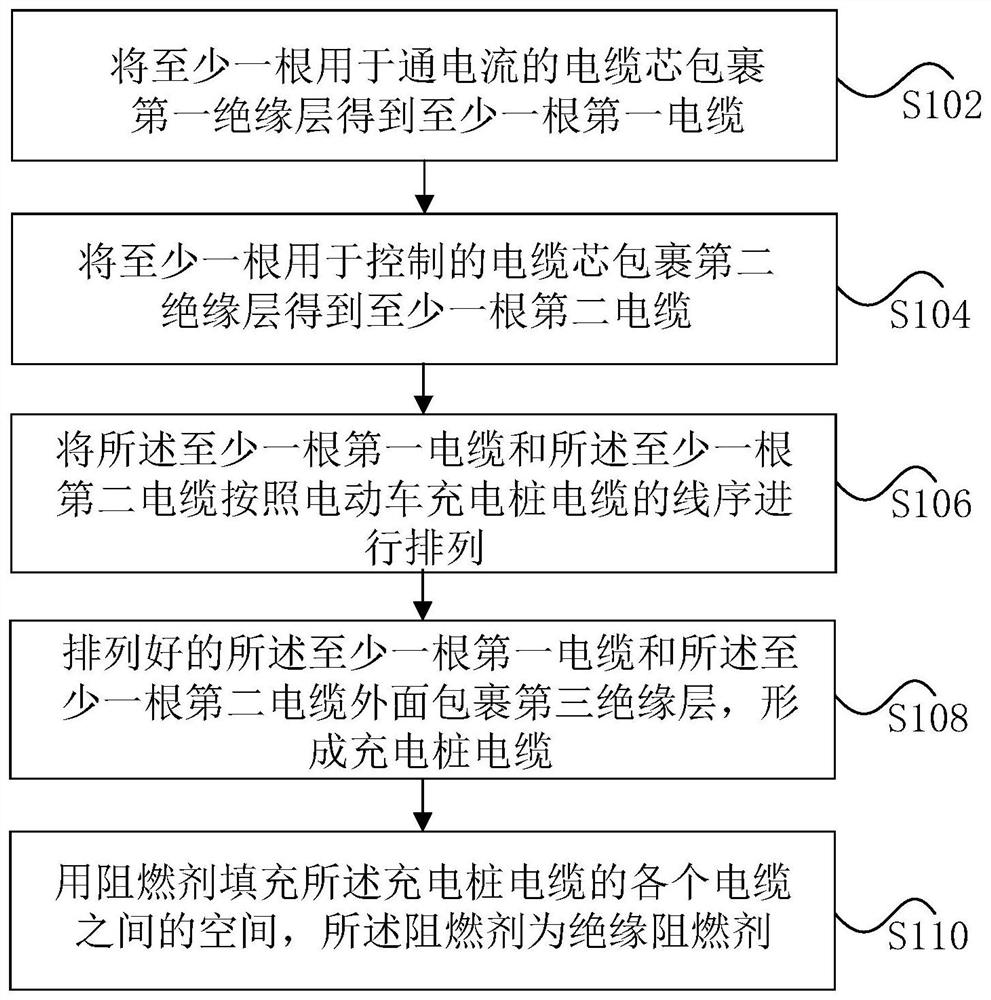

[0022] In this embodiment, a method of using a composite flame retardant to produce a charging pile cable is provided, figure 1 It is a flowchart of a method for producing a charging pile cable using a composite flame retardant according to an embodiment of the present application, such as figure 1 As shown, the process includes the following steps:

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap