Self-adaptive clamping device of vibration damper and implementation method of self-adaptive clamping device

A technology of clamping device and anti-vibration hammer, applied in the direction of cable suspension device, mechanical vibration damping device, etc., can solve the problems of inconvenient adjustment and non-adjustment, and achieve the advantages of improving adjustability, preventing detachment and increasing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

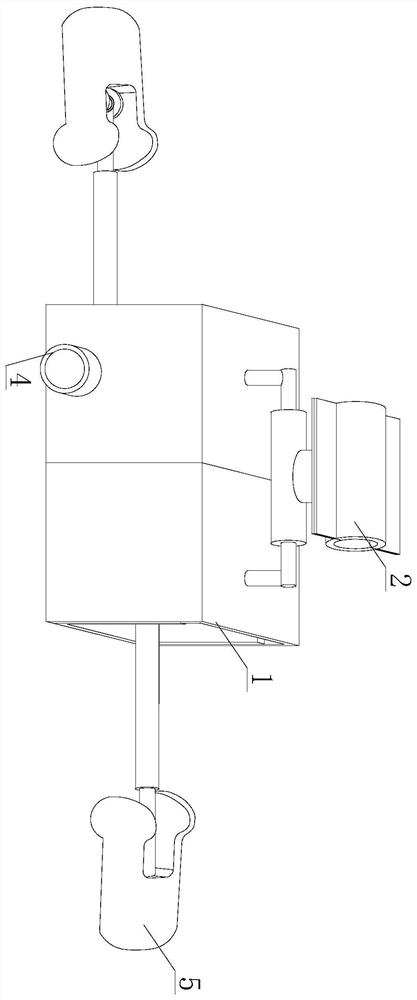

[0040] In order to better demonstrate the process of realizing an adaptive clamping device for an anti-vibration hammer, this embodiment proposes an implementation method for an adaptive clamping device for an anti-vibration hammer, including the following steps:

[0041] Step 1: Place the steel rod 51 connected to one end of the hammer head 52 between the upper clamping claw 34 and the lower clamping claw 36, and rotate the clamping motor 37 to drive the lower clamping claw 36 and the upper clamping claw 34 below Clamping is carried out between, the steel rod 51 is clamped and fixed;

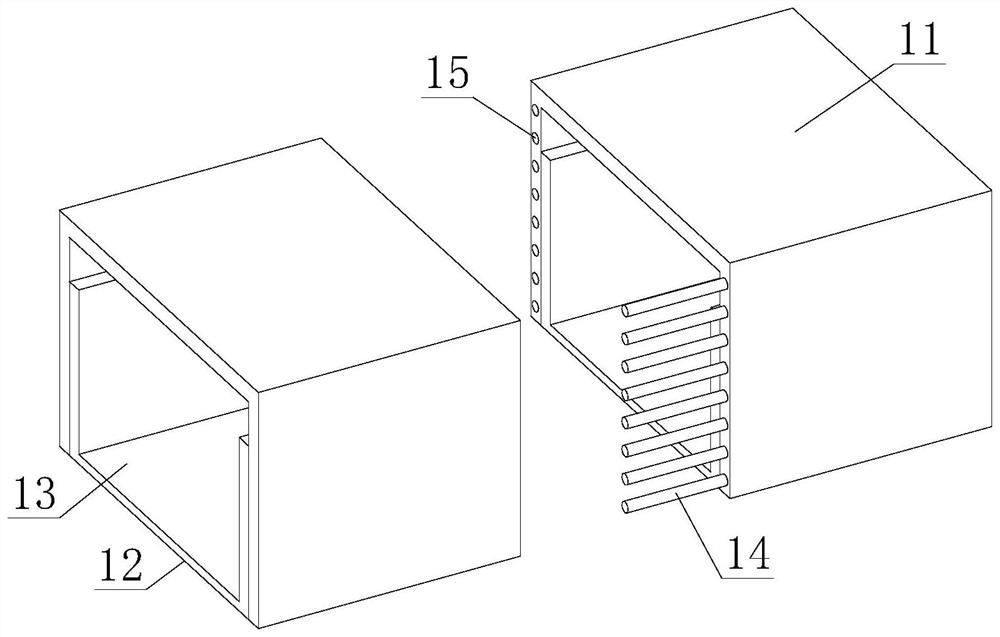

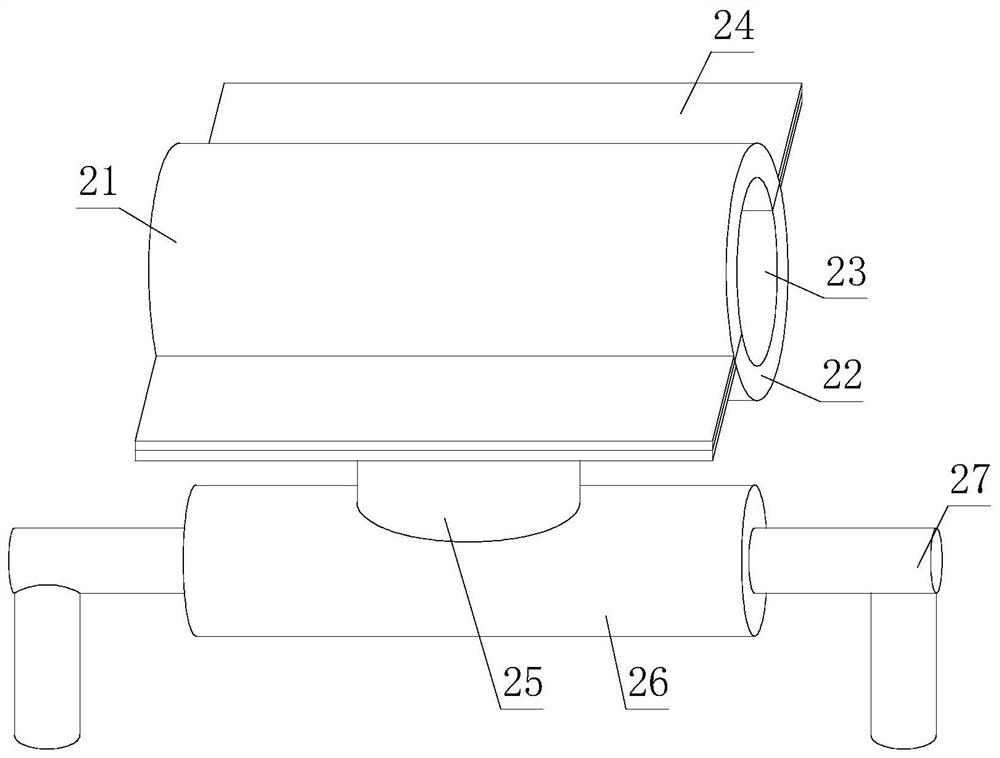

[0042] Step 2: After the anti-vibration hammer assembly 5 is installed, it is hoop-mounted on the wire through the upper hoop 21 and the lower hoop 22, and the two-way cylinder 26 drives the segmented upper cladding casing through the split connecting rod 27 11 and the inner casing 12 expand and contract, thereby adjusting the transverse spacing between the anti-vibration hammer assemblies 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com